Chemistry textbooks rarely spend much time on sodium phenoxide, yet its history reflects the steady march of industrial science. Born from the efforts of early chemists tinkering with phenol and alkalis in the nineteenth century, sodium phenoxide emerged as a workhorse for the burgeoning dye and pharmaceutical trades. In my own lab days, stories about the early German dye factories still echoed among older colleagues. Steam, glass flasks, and a dash of sodium hydroxide often marked the starting line for an army of derivatized organics, sodium phenoxide among them. The simplicity and reliability of its preparation made it a staple, even as more exotic reagents took over much of synthetic organic chemistry.

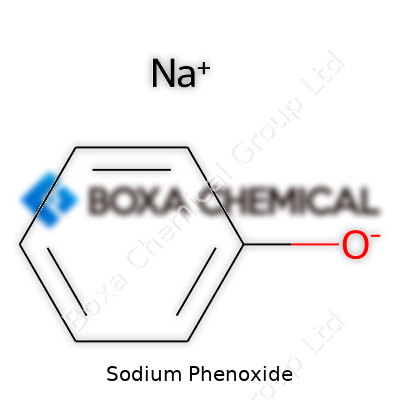

Sodium phenoxide stands as the sodium salt of phenol, carrying substantial utility wherever chemistry crosses paths with production lines. With a white to off-white crystalline appearance and a sharp odor that brings to mind household disinfectants, this compound doesn’t hide its origins. It’s the backbone in several chemical syntheses—dyes, pharmaceuticals, fragrances—thanks to its reactivity and its ready solubility in water and polar solvents. These features keep it on the shelves of industrial and academic labs alike, where it serves in everything from pilot-scale organic reactions to bulk synthesis.

This compound melts around 290°C and dissolves in water to form an alkaline solution—a trait that brings out its base-like properties. The sodium ion partners up with the phenoxide anion, taking what is otherwise a moderately acidic weak base (phenol) and transforming it into a much more reactive participant in organic chemistry. Its formula, C6H5ONa, hints at the transformation from a neutral aromatic molecule to one ready for nucleophilic attack and other sidechain substitutions. Its solutions show decent stability under normal conditions, but any exposure to acids sends it straight back to phenol.

Buyers expect sodium phenoxide to reach their doors at no less than 98% purity. Impurities, especially traces of sodium carbonate, can mess with yields in sensitive applications, so reputable producers list residual bases and moisture content on labels. Packaging tends to feature airtight, light-resistant containers—solid sodium phenoxide absorbs moisture and pulls in carbon dioxide from the air far too easily. HazCom labels warn users about the risks of burns and inhalation, reflecting its caustic nature and potential to irritate the skin and respiratory tract.

The most direct route still wins: reacting phenol with sodium hydroxide. Mix the two under gentle heating, and phenol’s weak acidity hands over a proton, crafting sodium phenoxide and water. In industrial installations, continuous flow reactors handle tons of reactants, but even a student can run this in a flask with decent ventilation and a mild exotherm. Alternative routes include sodium metal with phenol—this takes far more caution, as metallic sodium doesn’t play nice with moisture or organics except under the strictest controls.

Sodium phenoxide drives many textbook substitution reactions. The aromatic ring, now packed with extra electron density, jumps into Williamson ether syntheses—one classic route to phenyl ethers. In the dye industry, this same nucleophilicity gets tapped for coupling with diazonium salts, building azo dyes that earned their place during the early color revolutions of the Victorian era. Besides these, sodium phenoxide serves in preparing esters, polymers, and other functionalized aromatics, always thanks to the activation from deprotonation of the phenolic oxygen.

Other names float around in catalogs: sodium phenate, phenol sodium salt, sodium monophenolate. Each points to the same core product, though “sodium phenate” crops up most often in older literature and European registrations. Checking synonyms proves essential in regulatory paperwork or global procurement, as harmonized systems may give the impression of multiple chemicals when it’s one and the same.

Open a fresh bottle of sodium phenoxide without gloves and you’ll quickly appreciate its hazards. Chemical burns, skin irritation, and respiratory tract issues follow careless handling. I’ve seen rush-hour moments in the student lab where fume hoods save the day. OSHA guidelines demand eye shields, gloves, and proper ventilation, and with good reason: the powder becomes airborne easily and reacts vigorously with acids, strong oxidizers, and moisture. Disposal guidelines emphasize neutralization and dilution; collecting even small spills keeps workspaces safe. Properly run facilities drill their staff yearly on handling caustics like this to avoid costly or dangerous mistakes.

Walk through a dye or pharmaceutical plant, and sodium phenoxide turns up in batch lists for numerous products. It acts as a nucleophile in aromatic substitution, builds ethers, produces herbicides, goes into antioxidants, and sometimes turns up in resin synthesis. In the electronics sector, it helps produce intermediates for epoxy curing agents. Across my own experience assisting in organic synthesis scale-ups, the versatility and predictability of sodium phenoxide meant fewer surprises on the workbench or in the plant—a trait valued everywhere from R&D labs to commercial reactors.

Recent patents highlight tweaks on its preparation and reactivity. Some teams chase greener methods, using milder conditions or substituting phenol with biosourced derivatives. Spectroscopists use sodium phenoxide to probe aromatic substitution patterns, looking for substitution in the ortho-, meta-, and para- positions. Academic curiosity still digs into reaction mechanisms, refining the conditions for cleaner, higher-yielding reactions. I’ve also seen studies on resin hardeners and antioxidant additives that gave new roles to sodium phenoxide, reinforcing the compound’s long-standing utility in synthesis circles.

Researchers have scrutinized the effects of sodium phenoxide on animal and cell models. Acute oral exposure, even at modest doses, causes a range of effects: digestive upset, skin and eye corrosion, and, at higher doses, central nervous system symptoms. Chronic exposure presents broader risks, with focus on the potential for kidney and liver effects. Environmental impact studies show that sodium phenoxide, once in water, rapidly converts back to phenol—a substance regulated for its toxicity to aquatic organisms. Facilities working with this salt must document every aspect of their handling and emissions, both for worker safety and environmental protection.

Green chemistry points toward cleaner, safer, and more sustainable methods for making and handling sodium phenoxide. Teams working in process innovation keep tinkering with solventless reactions or using recycled sodium hydroxide. Future prospects include broader use in biosourced synthesis—where phenol and sodium hydroxide come from sustainable sources—and in high-tech applications such as specialty polymers, high-performance adhesives, and OLED precursors. Advances in encapsulation and microreactor technology might let producers scale down hazardous handling and boost precision, reducing exposure for workers and waste for communities. Even as new reagents come and go, sodium phenoxide’s utility, ease of preparation, and deeply studied chemistry will keep it relevant in many industrial and research landscapes.

Walk into a pharmacy, look around at pain relievers or fever reducers, and chances are, you’re seeing the indirect handiwork of sodium phenoxide. Most people outside chemical industries might not recognize the name, but this compound plays a role behind the scenes in making common medications. Sodium phenoxide helps produce phenol, which serves as a base for making acetaminophen and aspirin. In my undergraduate chemistry lab, we prepared a batch of phenol from sodium phenoxide, transforming powder into substance that matters for millions. Seeing the process firsthand, I realized not all important ingredients get a spotlight; still, their contributions filter down to the everyday things we rely on.

Sodium phenoxide enters the conversation wherever chemical synthesis crops up. In factories, technicians use it to make dyes for textiles, perfumes for daily use, and even some plastics that go into electronics. During my stint as a chemical research intern, we used sodium phenoxide for small-scale reactions, but in industry, they go big: it acts as a nucleophile, which makes it attractive for joining molecules together. Chromatic brilliance on your shirt and the scents in colognes trace back to compounds synthesized with its help.

Working in industrial chemistry, I noticed how sodium phenoxide’s reactivity can either speed up or slow down entire production lines. For example, creating salicylaldehyde—a starting material for fragrances and certain pharmaceuticals—counts on this compound to get the job done swiftly. Without it, companies would either need to shell out more for specialty reagents or settle for slower, pricier methods.

Researchers constantly tweak chemical reactions, hunting for cleaner pathways and fewer waste products. Sodium phenoxide steps in as a key intermediate to achieve those greener results. It reacts well with organic molecules, particularly in forming ethers and esters, which appear everywhere from industrial solvents to plastics. Chemists value the control it provides, making lab work safer and more reliable.

My own postgraduate work relied on sodium phenoxide derivatives when making ligands for metal catalysts. Small differences in preparation led to big changes in performance, showing how much rides on getting the starting materials right. It taught me that even a tweak at the beginning echoes throughout a project, impacting everything from costs to environmental impact.

Handling sodium phenoxide comes with its challenges. On its own, it can irritate the skin and lungs, so folks working with it suit up with gloves and goggles. Failures in training or ventilation can lead to bigger problems, especially inside factories where dust control isn’t optional. One solution connects directly to workforce investment: regular safety drills and updated equipment. In my experience, companies often resist short-term spending, but cutting corners backfires. Healthier workers and fewer accidents lead to smoother operations and reliable compliance with safety regulations.

Demand for sustainable products pushes chemists to find inventive ways to make and apply basic compounds like sodium phenoxide. Investing in processes that lower waste not only helps the bottom line, but also answers wider calls for cleaner manufacturing. From turning oil-derived phenol into something useful, to crafting safe, affordable medicine, sodium phenoxide doesn't attract headlines, yet it shapes dozens of products we rely on every day—often without us ever noticing.

Sodium phenoxide shows up in places where folks blend chemicals, develop dyes, and tinker with pharmaceuticals. It’s handy for making perfumes and certain medications. But convenience doesn’t erase its sharper edges. As someone who’s had more than a few run-ins with caustic chemicals, I’d never call sodium phenoxide a gentle companion. It can burn skin and eyes at the first splash. When mixing it in open air, the fumes can sting your nose and throat, leaving you wishing you’d given your goggles and gloves more respect.

This stuff won’t just dry out your hands; the burn can go deep. Even a light touch on damp skin can cause ulcers that hang around for days. Inhaled dust or mist leads to coughing and headaches, sometimes worse. According to the National Center for Biotechnology Information, exposure above 2 mg/m3 can trigger serious respiratory problems. Several animal studies tie repeated contact to liver and kidney damage. Unprotected eyes can take weeks to recover from a splash, sometimes never regaining full strength.

In my own lab days, the rules around sodium phenoxide always felt stricter than necessary. One spill changed my mind. It spread across a steel workbench, then lifted off with just a breath of air, giving two of us hacking coughs for hours. The warning labels ask for dry storage and sealed containers for good reason.

Workers handling sodium phenoxide every day face more than a few burns. Studies show traces of this compound in wastewater and lab drains can poison aquatic life. Even plants lose their shine when exposed to runoff. Drinking water can become contaminated if disposal isn’t strict, causing nausea and organ trouble for people nearby.

Exposure over weeks or months makes trouble inside the body, not just on skin. Nausea, dizziness, rapid heart rate—all these can come after breathing the dust or swallowing by accident. Research from the European Chemicals Agency points to possible genetic damage with high doses, connecting repeated exposure to a higher risk of mutations in test animals.

Folks sometimes trust thin gloves or a cheap mask, but sodium phenoxide shrugs those off. Thick nitrile gloves and heavy splash-proof goggles make all the difference. Good ventilation matters more than a fancy air filter. In workplaces, quick access to eyewash stations and showers saves a lot of pain. I always kept baking soda handy—old advice, but still useful for neutralizing accidental spills on skin.

Strict rules on labeling, storage, and disposal prevent sodium phenoxide from striking twice. Spill kits with absorbent powder, tight-lidded barrels for waste, and training for new staff mean fewer emergencies and less harm. Companies sticking close to OSHA guidelines see lower injury rates and cleaner records with inspectors, too.

People living near chemical plants, labs, or waste sites need clear updates about the chemicals in use, especially when it comes to hazards like sodium phenoxide. Local workshops, updated signage, and honest dialogue help everyone stay out of harm’s way. Trust grows stronger when companies and labs show neighbors exactly how risks are managed.

Sodium phenoxide won’t go away anytime soon, given its wide range of uses. That said, the risks run deep enough to demand real respect. Safety gear, tight lab protocols, and honest conversations about hazards all help stop simple mistakes from turning into permanent injuries or illnesses.

Growing up around construction and chemical work, you learn early that what you store and how you store it can make the difference between a safe day and a disaster. Sodium phenoxide plays an important role in labs and factories, used for dyes, pharmaceuticals, and as an intermediate in chemical syntheses. It reacts easily with water and can irritate skin and eyes. So, storing it safely never feels like overkill—it just makes sense.

No one wants to deal with a sodium phenoxide spill. The compound reacts with acids to produce toxic phenol and reacts with moisture to form caustic solutions. The dust can irritate the lungs. Improper storage raises risks for workers and the environment. Experience shows that even a small amount left open on a humid day will draw in water from the air and quickly cake up, or worse, start degrading—sometimes releasing those unmistakable sharp phenolic fumes that signal trouble.

The right container makes a world of difference. Airtight, corrosion-resistant containers like high-density polyethylene drums or glass with plastic screw-tops work well. Avoid metal, which may corrode or react. Avoid flimsy bags or poorly-sealed lids. A shelf stacked with leaky or mismatched containers turns a storeroom into a hazard, especially if acids or oxidizers are shelved nearby.

A dry place helps more than anything. High humidity speeds up decomposition and can make containers bulge or leak. Silica gel packs and desiccators keep excess moisture away, especially in coastal or rainy regions where humidity never really disappears. Never store sodium phenoxide anywhere near acids, oxidizers, or halogen compounds—one knocked-over bottle could set off a chain reaction.

Clear, easy-to-read labels with the date and hazard icons go a long way. Workers grabbing a canister at the end of a shift can’t guess at faded or vague markings. Labels cut down mistakes. The United Nations Globally Harmonized System (GHS) symbols aren’t there for decoration; they remind everyone what’s inside and what can go wrong.

Personal protective equipment isn’t just for newbies or for lab examiners. Gloves, goggles, and dust masks offer basic protection against accidental spills or splashes. In my experience, the most seasoned hands don’t get careless—they get careful from seeing firsthand what happens if you take shortcuts.

Routine checks matter. Look for signs of leaking, swelling, or corrosion. Rotate older stock first. Get rid of deteriorating material responsibly, using local hazardous waste programs. Reporting problems straight away keeps others safe; silence only compounds mistakes.

Any workplace dealing with reactive chemicals builds trust through good habits and simple routines. Proper storage of sodium phenoxide isn’t just about following rules. It’s about respect for the people working there, the neighbors nearby, and the water and wildlife outside. That mutual sense of responsibility, built day by day, keeps small mistakes from turning into big ones, and reassures everyone that the job is getting done right.

Sodium phenoxide stands out not just as an entry in a chemistry textbook. It’s a substance that gets used for real, practical reasons. In its usual form, it shows up as a white to slightly yellow, crystalline powder. If you pick up a container of it in a lab, you’ll notice it packs a bit of a punch—stored airtight to keep out carbon dioxide and moisture, since this stuff reacts quickly with both. This vulnerability says a lot about its basic nature. Sodium phenoxide belongs to a group called organic sodium salts, but its reactivity goes deeper than that label.

Add sodium phenoxide to water and you get a strong reaction. It dissolves pretty quickly, not quietly. The dissolved phenoxide ions respond by snapping up protons from the water, kicking out hydroxide ions and pushing the solution to become alkaline. That’s the kind of basic behavior that commands respect—and caution—when mixed with acids or materials sensitive to high pH. Even in storage, it can suck carbon dioxide out of regular air, forming sodium carbonate and phenol. This means even a carelessly sealed jar in a humid room starts breaking down, losing its punch for a chemist who counts on consistency.

Sodium phenoxide doesn’t take heat lightly. If you crank up the temperature, it doesn’t melt easily under normal conditions—heat instead encourages it to give off phenol vapors. Anyone who has gotten a whiff of phenol knows that isn’t pleasant and, in large amounts, it’s dangerous. This risk underlines the importance of smart handling in both laboratories and industry. Working around it means gloves, fume hoods, and plenty of respect for basic lab safety—not just for your own health, but for the whole facility.

This compound shows a whole other side in chemical synthesis. Its phenoxide ion is a strong nucleophile, making it a go-to ingredient for forming aryl ethers or synthesizing dyes, pharmaceuticals, and fine chemicals. Teams in labs rely on that nucleophilic power, but they also run into headaches. Sodium phenoxide reacts swiftly with acids, breaking apart and spewing out phenol. Control over concentration, temperature, and environment gives chemists the upper hand, but only with close attention. Skip a step and the reaction runs away—sometimes ruining a batch or raising safety concerns.

Some get too comfortable because sodium phenoxide sounds routine. The truth is, direct contact brings a risk of skin burns, and breathing dust or vapors can irritate the lungs. That’s not fearmongering—it’s what the evidence and accident records show. Chemical makers and lab researchers need proper training. That includes fast cleanup of spills and using protective equipment, not just for personal comfort, but for legal and health reasons. Storage protocols matter, too. Tight-sealing containers, cool rooms, and clear hazard labeling can stop a minor spill from turning into a major headache.

Having mishandled sodium phenoxide during my student years, I can attest that skipping over safety results in nasty surprises. Once, chasing a runaway reaction with this compound made it clear just how much a few overlooked details can snowball. Now, that experience hammers home why workers need thorough training and patience—especially when prepping solutions, measuring out reagents, or storing chemicals for months on a crowded shelf.

Sodium phenoxide steps into many labs as a trusted chemical for organic synthesis, dyes, and pharmaceuticals. Its power to react quickly earns it regular use, but this same reactivity brings serious hazards. Handling it carelessly can spark fires or send irritating vapors into the air. It can burn skin, eyes, and even corrode metal. The risks mean that every person working with it needs to show real respect for what it can do.

Speaking from experience, nobody walks away from a sodium phenoxide spill without learning something. Gloves, goggles, and lab coats aren’t optional extras; they’re essentials. One time, a bottle slipped from a classmate’s gloved hands. The powder scattered, and a whiff of that sharp odor quickly stung our noses. That day, only quick thinking—opening windows, using the eyewash station, grabbing the spill kit—kept it from becoming a bigger disaster. Afterward, we all remembered to double-check our grip and protect our faces, not just our hands.

Every set of safety rules starts with the basics: Nitrile gloves go on first. Heavy cotton or synthetic gloves can give a false sense of security; sodium phenoxide slips through thinner materials and burns before you realize it. Safety goggles need to shield side and front—not just cheap reading glasses. For those who deal with the chemical often, a full-face shield brings extra peace of mind. Wearing a buttoned-up lab coat with long sleeves cuts down on accidental splashes and skin contact.

Breathing in vapors or dust is no joke. Even a small dose can irritate throat and lungs, and over time repeated exposure links to lasting respiratory trouble. Masks rated for chemical dust and good ventilation work together. Relying on an old or broken fume hood basically means risking lung health; working without any hood means gambling with every breath.

Handling sodium phenoxide isn’t just about donning safety gear. Keeping the workspace dry and clear of clutter stops accidents before they start. Since the compound reacts with water, a tiny splash can trigger a violent response. Any storage area ought to stay cool, dry, and clearly labeled. There’s a reason experienced lab workers always check labels twice, and keep incompatible materials far apart—mixing sodium phenoxide with acids, oxidizers, or moisture leads to fire or toxic gas.

Years in the lab taught me the value of detailed training. Nothing replaces that—a clear procedure, step-by-step, and a team ready to help if things go wrong. Newcomers often rush, but patient mentors stop that impatience. Training sessions never get skipped. Emergency eye washes and showers stay clean and easy to reach. Spill kits live close to the workspace, not buried in a cabinet.

Accidents in labs come from shortcuts, missing labels, and forgotten safety drills. Clearest improvements keep people safer: upgrading gear, checking fume hoods often, running regular emergency drills, and teaching practical first-aid. Labs where everyone feels responsible for their safety see fewer incidents. Sharing real stories, not just reading rulebooks, gets the point across. People remember stories—especially the ones that almost went wrong.

In the end, sodium phenoxide asks for respect. Know how it acts, give it space, protect skin and lungs, and review safety steps again and again. Treating it lightly means risking far more than a ruined experiment. The right habits save hands, eyes, and sometimes, lives.

| Names | |

| Preferred IUPAC name | Sodium phenolide |

| Other names |

Sodium phenate Phenol sodium salt Sodium monophenoxide Sodium oxybenzenide |

| Pronunciation | /ˈsəʊdiəm fɪˈnɒksaɪd/ |

| Identifiers | |

| CAS Number | 139-02-6 |

| Beilstein Reference | 1365053 |

| ChEBI | CHEBI:40585 |

| ChEMBL | CHEMBL142411 |

| ChemSpider | 54661 |

| DrugBank | DB09437 |

| ECHA InfoCard | 100.004.483 |

| EC Number | 205-281-5 |

| Gmelin Reference | 6763 |

| KEGG | C01842 |

| MeSH | D010724 |

| PubChem CID | 8659 |

| RTECS number | SJ3325000 |

| UNII | 09H2W3205K |

| UN number | UN2879 |

| Properties | |

| Chemical formula | NaOC6H5 |

| Molar mass | NaOC6H5: 116.09 g/mol |

| Appearance | white powder |

| Odor | characteristic |

| Density | 1.21 g/cm³ |

| Solubility in water | Soluble |

| log P | 0.98 |

| Vapor pressure | Negligible |

| Acidity (pKa) | pKa ~10 |

| Basicity (pKb) | 9.88 |

| Magnetic susceptibility (χ) | -47.5 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.512 |

| Viscosity | 1.12 mPa·s (at 25 °C) |

| Dipole moment | 2.50 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 110.3 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -395.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -523.5 kJ/mol |

| Pharmacology | |

| ATC code | N02BE05 |

| Hazards | |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H318, H335 |

| Precautionary statements | P280, P305+P351+P338, P310, P264, P270, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 1,2,0 |

| Flash point | 79°C |

| Autoignition temperature | 685°F (363°C) |

| Lethal dose or concentration | LD50 oral rat 980 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50: 980 mg/kg |

| NIOSH | MW8225000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 mg/m3 |

| Related compounds | |

| Related compounds |

Phenol Potassium phenoxide Sodium hydroxide |