Nonylphenol has been around for decades. Chemists chasing better surfactants found nonylphenol by tweaking phenols with branching nonyl groups back in the early 20th century. As plastics and detergents grew in industrial use, so did nonylphenol-based surfactants. You’ll spot the fingerprints of the chemical revolution of the 1960s all over nonylphenol’s story. Demand soared as cleaning products and plastics boomed. What looked like an answer to industrial needs soon brought new problems along for the ride. As environmental awareness grew in the 1970s, scientists began questioning nonylphenol’s downstream effects, especially where rivers were turning toxic near chemical plants. Industry grew up around the stuff, but so did the calls to limit its harm. In my own research, I've seen how fast regulations shift once the public catches wind of the risks. Some companies adapted regulatory hurdles, while others stuck with what they knew as long as possible.

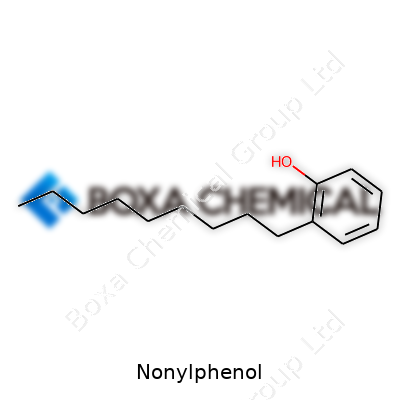

Nonylphenol isn’t one thing; it's a blend, a basket of similar molecules with that core phenol ring and long, nine-carbon nonyl group that branches out. It’s oily, sticky, and persistent. The mix makes it perfect in some ways for detergents and emulsifiers, but that same persistence is why it sticks around in soil and water. Factories produce nonylphenol in bulk. You’ll see big tanks labeled NONYLPHENOL, gear-up crews in thick gloves—they know spills linger for a long time. It's all about balance: what works for pulling grease from fabric, or homing oil mixtures, can unleash a headache for anyone tracking pollution.

Slippery, slightly yellowish, with a sharp, phenolic smell that makes you back away fast if you get too close—nonylphenol’s physicality stands out in any chem lab. At room temperature, it’s liquid, though thicker than water, and it doesn’t dissolve easily unless you use organic solvents. You can feel that greasy texture even through gloves. Boiling point? Expect a climb above 290°C—pretty high for anything you might work with daily. Nonylphenol doesn't break down easily under sunlight or heat, and that's a big part of the environmental problem. In chemical handling, you notice it has a moderate vapor pressure, meaning there’s always a whiff in the air if you're around a lot of it. These characteristics give nonylphenol its performance edge in manufacturing but its tenacity in the environment.

Labeling mandates have tightened up since the 90s. All containers need to mark concentration, UN number, hazard symbols, and clear handling instructions. The color-coded drums you see in warehouses help workers keep the right distance. In technical sheets, nonylphenol content is important—most industrial blends run between 85% to 90% nonylphenol, with the rest made of isomers and trace impurities. Shelf life stretches for years if you keep the drum sealed and out of sunlight. Specifications require regular checks for purity and water content since both affect how the product acts in downstream mixes. Safety data sheets warn about keeping it away from acids and oxidizers, since you can spark strong exothermic reactions.

Nonylphenol springs from alkylation chemistry. You start with phenol, react it with nonene—a nine-carbon alkene—using strong acid catalysts like sulfuric acid or solid resin. Inside a high-pressure reactor, the mixture heats and churns for hours. The batch turns dark, smells sharp, and the end product needs careful purification. Distillation pulls off lighter fractions, and base neutralization washes clean the acid traces. Factories push for efficiency, but they still get a soup of branched nonylphenol isomers because nonene itself is not a single thing. Each batch means careful testing before a shipment heads to a customer, since impurities can mess up downstream performance and safety. Most producers spend decades refining how to make the batches consistent while dealing with hazardous waste safely.

Chemists don’t use nonylphenol just as-is. The trick is turning nonylphenol into nonylphenol ethoxylates. You tether ethylene oxide molecules onto the phenol, working in reactors with strict temperature and pressure controls. Those nonylphenol ethoxylates turn into the workhorses of cleaning and emulsification: they break up dirt, suspend oil, and help plastics grab color. The ethoxylation process opens a toolbox for tweaking how well a detergent foams or how fast it breaks down. Some teams have tried sulfonating nonylphenol or adding other functional groups, but the core business still revolves around cleaning and dispersing benefits from ethoxylation.

Nonylphenol goes by a lot of names. Commercial invoices and chemical supply chains tag it as NP, p-nonylphenol, or para-nonylphenol. MSDS documents may list synonyms: Isononylphenol, Nonoxinol, or sometimes just “alkylphenol.” Brand names depend on the manufacturer—Dow, BASF, and other giants have their house brands and grades, but underneath the trade dress, it's similar chemistry. Some product codes help buyers know how pure a batch is or what kind of isomer makeup it has, which matters for getting the properties a customer wants.

Working with nonylphenol pulls a heavy focus on safety. Companies train staff to use splash goggles, chemical gloves, and keep ventilation running strong. In the loading docks, written procedures cover every step: double-checking label numbers, following spill drills, storing drums on spill mats. You can’t underestimate the potential damage from accidental exposure—skin contact burns, inhalation irritates the lungs, and swallowing brings a rush to the first-aid cabinet. Fire response teams keep dry chemical extinguishers near storage areas, as water just spreads a burning puddle. Environmental codes demand that spilled nonylphenol never heads into the sewer; it gets captured for special waste treatment.

Nonylphenol’s fingerprints show up everywhere from factory floors to suburban kitchens. It plays a major role in manufacturing detergents, industrial cleaners, pesticides, some plastics, and automotive fluids. Paper mills use nonylphenol formulations to help inks spread evenly, while textile plants improve dye uptake using these surfactants. Construction industries rely on its emulsifiers in concrete additives, giving products a consistency that lands on job sites all over. Small amounts end up in lubricants and hydraulic fluids. Every time you use a cleaning spray, there’s a good chance some ingredient downstream once passed through a nonylphenol reaction.

Teams worldwide keep pushing for greener, safer replacements. The labs I've visited at universities and specialty chemical makers are packed with trials to swap out nonylphenol for alternatives with less environmental baggage. They blend plant-based surfactants or create new polymer substitutes, running them through endless wash tests and degradation studies. Researchers track nonylphenol content in rivers, lakes, and sewage; the data keep piling up, showing stubborn persistence. In some countries, you see tight regulations forcing companies to switch, while other markets continue the old way, mostly due to limited testing infrastructure and high costs of change. R&D budgets skew bigger each year for this kind of 'chemical phase-out,' but sheer volume keeps nonylphenol on the shelf for now.

The alarm bells started ringing as soon as scientists began noticing nonylphenol hanging around long after factories dumped rinse water. Ecotoxicologists ran fish studies—some right in the discharge zones near chemical plants—and started linking exposure to reproductive disruptions in fish. It doesn’t stop with wildlife; researchers found traces in sewage sludge, river mud, even groundwater used for farming. Health concerns center on nonylphenol's ability to mimic hormones, especially estrogen, raising flags for both wildlife and humans. Europe and North America kicked research into high gear, tracking bioaccumulation in food chains. EPA reports and academic reviews paint a tough picture—nonylphenol lingers, travels, and disrupts long after industrial use. The sheer stubbornness of the molecule in soils and sediments means bans alone don't fix the legacy problem. In my own career, I’ve spoken with groundwater experts who spent years tracing contaminated aquifers back to spills decades old, showing how deep this issue runs.

Nonylphenol’s days look numbered in most affluent markets, with legislative pressure building for total bans or tight controls. The chemical industry knows reform is on the agenda; lobby meetings center on cost, workable timelines, and technical substitutes. Faster adoption for green surfactants comes with a price: new factories, product development, and regulatory reviews that drag for years. While nonylphenol still moves in global supply chains, especially in markets with lighter rules, consumer awareness grows with each report of fish kills or tainted water. Responsible players in the business shift research budgets toward new molecules or look to repurpose existing ‘greener’ tech for cleaning and production. I’ve noticed honest conversations growing between regulators, industry, and environmental groups—everybody wants performance, but nobody wants the mess. Until a new standard product reaches everywhere, the patchwork between advanced and emerging markets will continue, and the environmental legacy—soils, rivers, and wildlife still carrying traces decades from now—won't shake free quickly. In labs and offices alike, the work continues, driven by data, regulation, community health, and a deepening sense that the age of easy chemistry now comes with a heavy bill.

Walk through a hardware store and pick up a bottle of industrial cleaner. Odds are good, nonylphenol played a role somewhere in its production. Nonylphenol acts as a building block for certain chemicals called surfactants. These surfactants help break down grease and dirt, making them key to powerful detergents, paints, and emulsifiers. Homeowners probably don’t recognize the name, but large-scale farming and textile businesses buy up tons of nonylphenol-based products to clean equipment and process materials.

Manufacturers lean on nonylphenol because it cuts through oils and helps other chemicals blend easily. Pulp and paper mills, for example, add nonylphenol derivatives to bleach and treat raw fiber. Textile plants add it to dye baths so colors hold fast and don’t fade. Some plastics plants use nonylphenol compounds to mold products like rubber belts and hoses, giving those items flexibility and strength. Even paints use it to keep pigments smooth and surfaces shiny.

I once toured a factory that made industrial detergents. Staff wore heavy gear to handle chemicals, but runoff from cleaning tanks left puddles in the parking lot. That stuck with me, because nonylphenol doesn’t just stay in the plant. Once it flows into waterways, fish and other small creatures start showing strange behavior. Nonylphenol can build up in the food chain, and studies show it affects hormone systems in both animals and humans.

Research from the United States Environmental Protection Agency highlights that nonylphenol lingers in soil and water longer than many everyday pollutants. The substance likes to stick to particles and doesn’t break down quickly, leading to long-term exposure risks in rivers and lakes. The European Union placed serious limits on its use, citing the harmful effect on aquatic life and possible threats to drinking water.

Cost drives a lot of decisions here. Nonylphenol does its job efficiently at a lower price than many alternatives. Small companies, running on tight budgets, rarely jump to newer, more expensive chemicals if regulators still allow nonylphenol. Engineers know it’s reliable and easy to source. Chemists trust its performance in blends they have used for years, making the switch to safer chemistry a big ask.

Switching away from nonylphenol won’t happen overnight. Industry needs more practical, affordable ingredients that do the same job without harming wildlife or drinking water. Some companies have tried safer alternatives, like alcohol ethoxylates. These break down faster and leave fewer traces in rivers and fields. Governments can encourage change with clear rules and support for research. Consumers can help too—by choosing certified eco-friendly cleaners or writing to brands about chemicals in their products.

Each person who reads a label or pushes for cleaner products makes a small difference. With shared effort between policymakers, manufacturers, and regular people, a cleaner, less toxic future isn’t just an abstract wish—it can become reality. I’ve seen communities clean up rivers and demand accountability from local plants. That kind of action stands as proof: people make better choices when they have the facts.

Nonylphenol finds its way into a lot more corners of our lives than many folks realize. It's tucked into industrial detergents, laundry pods, all-purpose cleaners, and even some personal care products. Walk past a factory, a recycling plant, or down the aisle of strong-smelling floor-cleaners, and it’s easy to catch a trace. Nonylphenol acts as a surfactant—helping oil and water mix, lifting up grime, and making products look cost-effective for big operations.

Scientists started raising flags about this chemical back in the late 1980s. I remember talking to a wastewater engineer who practically groaned when the topic came up—he’d seen what Nonylphenol does in water, especially after rainstorms sweep out city drains. Fish started changing sex in polluted streams, and certain frog species saw weird drops in numbers.

People sometimes shrug off these changes in wildlife, thinking it doesn’t touch human health. It does. Nonylphenol acts as an endocrine disruptor, which means it tinkers with hormones in both animals and people. Studies show Nonylphenol mimics estrogen, the hormone that steers everything from reproduction to mood swings. One report from the US Environmental Protection Agency linked repeated exposure to Nonylphenol with reproductive problems and developmental issues in lab animals. A study out of Europe linked it to lower sperm counts and delayed puberty in boys.

It builds up in fat tissue, so over time, even trace levels turn into bigger worries. Cooking, cleaning the house, even washing athletic gear—all can chip away at long-term health if these products rely on Nonylphenol. The risk isn’t about instant poisoning; it’s the slow build-up, generation after generation, that makes the picture more urgent. People with immune issues, or pregnant women, are hit harder.

Researchers measured Nonylphenol in breast milk, drinking water, and even fresh produce. Some cities tested municipal water supplies and caught traces. Europe moved fast—by 2003, most countries banned its use in household cleaners and many industrial processes. China and the US took longer but now keep their own growing lists of restrictions and product recalls.

The science keeps shifting, too. In one field study, a river near an industrial park showed Nonylphenol at levels strong enough to knock out half the fish population in a few years. Yet clean-up groups managed to cut background levels by switching to safer alternatives like alcohol ethoxylates and better plant filtration. I volunteered in water testing projects, and it’s wild to see the difference just a few years of smart policy and consumer pressure can make.

People often wait for the government to act, but consumers have power at the register. Look for household brands that switch to safer surfactants. Read ingredient labels, push store managers for safer options, send emails to companies. For cities and factories, swapping in less-harmful alternatives takes up-front investment, but less money gets spent down the line on healthcare and environmental cleanup.

There’s something honest about paying attention to the products we use, knowing where they end up after we flush or rinse them, and pushing for changes that ripple through the whole supply chain. Nonylphenol’s story comes down not just to chemistry, but to choices—whether we keep relying on short-term cost savings or invest in healthier communities for the next generation.

Nonylphenol has a bit of a reputation, and for good reason. Used in everything from detergents to plastics, it can sneak into water supplies and stick around longer than you’d like. Research from the U.S. Environmental Protection Agency points out links between nonylphenol and hormone disruption in wildlife. In my days working at a wastewater facility, seeing the warning placards gave me more than a hint that this was not a substance to stash away like corn syrup.

I remember one colleague describing the smell—strong, sharp, not something you forget once you’ve come across it. Nonylphenol creeps through the air, so one key step: keep it sealed up tight. Tanks and drums must stay shut. Leaky valves or careless caps send vapors rolling through a warehouse fast. Skip the casual approach here—dedicated, labeled containers beat makeshift buckets every time.

In a chemical storeroom, workers avoid bright lights for more than mood. Nonylphenol burns at high temperatures, and a little spark can ruin a good day. Fire codes call for placement far away from ignition sources, and plenty of ventilation. From firsthand experience, grouping incompatible chemicals leads to accidents, not just warnings on paper. Shelves marked for only flammable liquids or acids send a clear message: mix-ups cause trouble.

The stuff stings skin and eyes, so gloves, aprons, and goggles become standard kit. I never met anyone who enjoyed getting splashed by it. Fact sheets list nitrile gloves as a must, and I’ve seen people skip this only to rush for the eyewash station. Spills don’t just harm one person—vapors spread out, so simple surgical masks won’t help. Proper respirators, checked and fitted, should come out any time there’s a risk of a splash or spill.

Spills happen. Once, a drum rolled the wrong way and dumped its load. Because we’d rehearsed spill cleanup, absorbent pads and spill kits came out fast. No one stood around asking what to do—someone shut the door, someone else called the supervisor. Getting lazy about this step just makes a bad situation worse. Having emergency showers and eyewash stations within reach seems obvious, yet many older buildings still lack them.

Nonylphenol doesn’t just evaporate and disappear. European regulations have brought tighter controls, limiting how much can escape into the environment. Here in the US, rules spell out storage volumes and container types. But no guideline beats a walk-through: check storage logs, inspect seals, and lock up the area at every shift change. Training matters, and nothing replaces hearing from someone who has dealt with a real mess. In my experience, the best safety policies get updated after a near miss, not just after reading the latest regulation.

Some companies look for safer alternatives that break down faster and don’t linger in groundwater. Newer surfactants with less environmental impact may reduce reliance on nonylphenol, helping both workers and the planet. Regular training, strict labeling, and reliable ventilation don’t just follow best practices—they protect families living near plants and workers heading home at the end of the day. Keeping a hazardous chemical tucked away isn’t enough; those who work around it know the true value of respect and preparation.

Nonylphenol turns up in detergents, plastics, pesticides, and a long list of household and industrial goods. Its use isn’t just a technical detail—this stuff follows the water. It enters rivers, streams, and lakes, surviving sewage treatment in ways that raise questions about priorities and safeguards. I’ve seen reports from community monitoring groups that show fish and tiny aquatic creatures struggling or vanishing where nonylphenol levels spike. That’s not a blip. Over time, the chemical resists breaking down, building up in sediment and wildlife. Many communities downstream feel the effects, even if they rarely hear its name.

Science points to nonylphenol acting like a hormone once in the environment. Fish exposed to it change, sometimes developing both male and female traits. This isn’t just a lab curiosity. Over years, reproductive cycles break down. Commercial fishers in some regions end up with empty nets, while native fish vanish from old fishing holes. Fewer creatures in these food webs means more algae blooms, muddier water, and a sharp drop in nature’s resilience.

Eating local fish and shellfish used to mean a fresh, affordable meal. Now, over time, traces of nonylphenol move up the food chain. Lab analyses of fish, shellfish, even water birds and farm animals, frequently pick up residues. Families living close to affected waters face uncertain health risks with every bite, especially children. Nobody wants toxic chemicals in their dinner, but with nonylphenol, it’s not always a choice.

Nonylphenol slips past many old-school wastewater plants almost unchanged. Factories and urban runoff add more to the mix. Some countries ban or restrict it, but others lag, including places with fast-growing cities and industry. I remember seeing a river in the dry season, foam collecting downstream of an industrial area, while officials claimed the water met standards. High rainfall just spreads the load further, and no regulator actually tracks every backyard drain or small business. Every small input sums into a bigger mess farther downstream.

Companies have swapped nonylphenol out for safer replacements in some products, especially after stricter regulation in Europe and parts of North America. Green chemistry offers options: scientists work on surfactants that break down quickly and don’t mess with hormones. Responsible brands have moved to public ingredient lists and third-party certifications to reassure families and buyers.

But stronger oversight alone won’t solve everything. People ask more questions about what goes into soaps and cleaners at the grocery store. Community groups test their creeks and push for better treatment systems. Local governments can prove what real transparency looks like. Industry can fund water restoration, not just advertise a new recipe. These changes often start with neighbors—not big announcements. Nonylphenol pollution can shrink when everyone pushes for clear labeling, next-generation water treatment, and open data. I’ve seen places where this teamwork works, with cleaner water and healthier fish just a few years after new rules kick in.

People don’t talk about nonylphenol much, yet this chemical traces through so many goods in stores and under sinks. Factories use it in detergents, paints, pesticides, and plastics. Its value to manufacturers is clear—nonylphenol helps clean, break down grease, and acts as an effective surfactant. Yet this very chemical has a knack for flowing into waterways once it leaves our homes or ends up in runoff from factories.

Concerns about nonylphenol start stacking up the moment it hits the water cycle. Fish and aquatic life face real risks from even small amounts. The substance likes to build up in tissues, and piles of evidence link it to hormone disruption in fish populations. The European Chemicals Agency pointed out how nonylphenol acts like estrogen in fish, throwing off breeding patterns and wreaking havoc on ecosystems. Many people couldn’t name the chemical, but its side effects ripple through lakes and streams.

Scientists started flagging nonylphenol’s dangers in the ’80s, noting how it persisted for ages in water and soil. Studies showed nonylphenol could even end up in human food through contaminated fish and crops. Health agencies and environmental groups pushed for limits. The European Union stepped in with strict restrictions, banning nonylphenol in many products since 2003. Europe’s REACH regulations limited the use and focused industry attention on finding safer alternatives, especially for detergents and household cleaners.

By the early 2010s, Canada and Japan also tightened controls, cutting back industrial releases. They set maximum levels in drinking water and placed it on lists of substances companies must track. In the United States, the Environmental Protection Agency pressed for voluntary reductions from industry, then went further, including nonylphenol on its list of chemicals requiring close review. In some states, regulators started setting surface water quality standards, keeping nonylphenol beneath levels considered safe for aquatic life.

Cleaning up nonylphenol from wastewater remains tricky and costly. Facilities with outdated treatment systems let much of it slip through. Some manufacturers moved to alternative detergents, but not every replacement is safer or proven in the long run. Smaller companies sometimes struggle to switch, balancing costs against customer expectations and regulatory pressure.

As shoppers, we rarely get to see what’s in our cleaning products or household goods. Other countries push for better labeling, and a few retailers commit to removing suspect chemicals from store shelves. Knowing what goes down the drain each day needs more attention from all of us—folks who buy, use, and toss these products.

Cleaner waterways don’t just hinge on one rule or one agency. Stronger laws must meet honest enforcement, along with research into safer chemicals that do the same work. Facilities that treat wastewater need upgrades, and industrial audits catch careless releases before rivers pay the price. On top of that, real education about what risks come with daily use makes a difference.

I’ve seen firsthand in towns with legacy pollution—change doesn’t come overnight. Still, mounting science points the way. When policies actually shift buying habits and manufacturing choices, fish and people both gain. Regulators, industries, and communities each shoulder a part in the puzzle, but clearer rules and greater transparency can cut the risks tied to toxic chemicals like nonylphenol.

| Names | |

| Preferred IUPAC name | 4-nonylphenol |

| Other names |

isononylphenol p-nonylphenol 4-nonylphenol nonyl phenol |

| Pronunciation | /ˌnɒnɪlˈfiːnɒl/ |

| Identifiers | |

| CAS Number | 25154-52-3 |

| Beilstein Reference | Beilstein Reference: 2041465 |

| ChEBI | CHEBI:28619 |

| ChEMBL | CHEMBL111 |

| ChemSpider | 6549 |

| DrugBank | DB13877 |

| ECHA InfoCard | 03d3e6e5-05e6-4199-94ed-f430c08aef47 |

| EC Number | 203-984-1 |

| Gmelin Reference | 68218 |

| KEGG | C06537 |

| MeSH | D009746 |

| PubChem CID | 31248 |

| RTECS number | RB8020000 |

| UNII | 3I913P585S |

| UN number | UN 3082 |

| Properties | |

| Chemical formula | C15H24O |

| Molar mass | 220.35 g/mol |

| Appearance | colorless to pale yellow liquid |

| Odor | Phenolic odor |

| Density | 0.953 g/cm³ |

| Solubility in water | 5.43 mg/L (25 °C) |

| log P | 4.48 |

| Vapor pressure | 0.3 mmHg (20°C) |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 7.89 |

| Magnetic susceptibility (χ) | -7.6e-6 |

| Refractive index (nD) | 1.541 |

| Viscosity | 11-15 mPa.s (at 25°C) |

| Dipole moment | 4.63 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 389.06 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -435.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6040.7 kJ/mol |

| Pharmacology | |

| ATC code | D08AX99 |

| Hazards | |

| GHS labelling | GHS07, GHS05, GHS08, GHS09 |

| Pictograms | GHS05,GHS07,GHS08,GHS09 |

| Signal word | Danger |

| Hazard statements | H302, H314, H400, H410 |

| Precautionary statements | P260, P273, P280, P301+P310, P305+P351+P338, P308+P313 |

| NFPA 704 (fire diamond) | NFPA 704: 2-2-4 |

| Flash point | 158°C |

| Autoignition temperature | 330°C |

| Explosive limits | Explosive limits: 2.3–11% |

| Lethal dose or concentration | LD50 (oral, rat): 1620 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Nonylphenol: "580 mg/kg (rat, oral) |

| NIOSH | SDC6300000 |

| PEL (Permissible) | 5 mg/m3 |

| REL (Recommended) | 0.5 mg/m³ |

| IDLH (Immediate danger) | 50 ppm |

| Related compounds | |

| Related compounds |

Bisphenol A Nonoxynol-9 Octylphenol Phenol Alkylphenol Nonylphenol ethoxylate |