M-Ethylphenol has a long track record in organic chemistry, tracing its roots back to the surge of phenolic chemistry in the late 19th and early 20th centuries. As chemists started to harness the potential of aromatic hydrocarbons, m-ethylphenol found its place in both laboratory benchwork and industrial synthesis. Its journey began in coal tar processing, where extraction techniques first laid the ground for purity demands in production. Over the decades, the compound found new relevance when the scent and chemical industry began seeking stable, customizable building blocks for more complex molecules. The history of using m-ethylphenol stands as an example of how an initially modest byproduct evolves alongside shifting scientific focus.

M-Ethylphenol, or 3-methylphenol, lands in the category of substituted phenols, offering unique chemical behavior because of its methyl group positioned meta to the hydroxyl. Manufacturers and researchers value it for its consistent reactivity and achievable purity. Its relevance doesn’t rest only in theoretical or industrial circles—its presence appears tangibly, from antiseptic blends to resin synthesis routines and flavor development. Products often benefit from this compound’s moderately volatile nature and manageable reactivity, paving the way for controlled downstream processing.

Typical samples of m-ethylphenol manifest as colorless to pale yellow liquids, each batch carrying the sharp, medicinal odor reminiscent of phenolic derivatives. With a melting point near 11°C and a boiling point approaching 202°C, handlers find flexibility both for storage and transformation. Solubility trends show moderate interaction with water, improving in alcohols or organic solvents, which means practical cleanup and formulation steps don’t demand aggressive measures. Its molecular formula C7H8O, coupled with a molecular weight of 108.14 g/mol, provides an approachable structure. The electric dipole created by the methyl and hydroxyl groups maintains a balance, accounting for the compound’s strong attraction in electrophilic substitutions.

Producers offer m-ethylphenol typically at purities exceeding 98%, in quantities that fit kilo-lab, pilot, or plant scales. Labels show not just concentration but also specific gravity, acid dissociation constant, and a certificate of analysis for impurities such as ortho- and para-isomers. Batch-to-batch verification remains a big point—no user wants an unexpected reaction profile or reduced yield just because of an overlooked contaminant. Properly marked containers indicate both the chemical name and a list of plausible physical hazards, such as flammability and corrosiveness, as dictated by international transport and storage standards.

Most large-scale production of m-ethylphenol follows the methylation of phenol using methylating agents under controlled temperature and pressure. Friedel–Crafts alkylation remains a workhorse process, featuring catalysts like aluminum chloride, but newer green chemistry techniques are gaining ground, focusing on selectivity and lower environmental footprint. The challenge always revolves around separating the meta-isomer efficiently from ortho and para products, as the underlying reaction doesn’t inherently favor one over the others. Fractional distillation at precise conditions often closes the gap, followed by crystallization for purity upgrades.

The methyl group and phenolic hydroxyl together open m-ethylphenol up to a versatile range of transformations. Electrophilic substitution at the remaining ortho and para positions gives access to further alkylated or halogenated derivatives, useful in customizing resins and dyes. The hydroxyl permits etherification, esterification, or oxidation to quinones, each of these transformations building new commercial outlet channels. Its moderate acidity enables mild reactions, preventing overreaction in multi-step syntheses—a consistent reason why it shows up in fine chemical catalogs.

In the marketplace and literature, m-ethylphenol also goes by 3-methylphenol and m-cresol. CAS number 108-39-4 typically shows up on product data sheets. Other historical or specialized sources might refer to it as 3-hydroxytoluene. These names often slip into documentation, regulatory filings, and material safety data sheets, creating a web of references for users to navigate, especially when sourcing globally.

Handling m-ethylphenol requires a steady respect for both personal and environmental safety. Direct exposure risks include skin sensitization, respiratory irritation, and potential organ system impacts in high doses. Industries stress the use of gloves, splash goggles, and controlled ventilation. Regulatory frameworks, such as those from OSHA and the European Chemicals Agency, enforce exposure monitoring and rigorous documentation at each processing step. Spill response plans save time and reduce risk, as this compound’s mobility can turn a minor leak into a costly decontamination if left unchecked. Waste must be managed by incineration or specialized treatments—no one wants residual phenolics entering groundwater or soil.

Demand for m-ethylphenol comes from several directions. Producers of phenolic resins rely on its reactivity and cost-effectiveness when tailoring adhesives or coatings for construction, automotive, and electronics. Its antimicrobial nature, in combination with other phenols, leads to roles in cleansers, antiseptics, and even some anesthetic preparations. In flavor and fragrance chemistry, its nuanced aroma fills gaps between smoky, medicinal, and sweet profiles, adding complexity to processed foods and scented products. Research laboratories frequently turn to m-ethylphenol as a feedstock or intermediate when probing the behavior of substituted aromatics or testing new catalytic systems.

From my own work in chemical synthesis, tracking innovations around m-ethylphenol shows both traditional and frontier science. Universities and institutes have tried to refine catalytic efficiency, reduce energy costs, and minimize byproducts, all to ease downstream processing and lower the environmental load. The drive for selective methylation or cleaner solvent systems keeps researchers busy, as the cost and regulatory climate constantly shift. Some recent efforts focus on biosynthetic pathways, leveraging microbial enzymes to produce m-ethylphenol from renewable substrates—an exciting move that might eventually sidestep some of the current pollution concerns.

Toxicologists focus on short-term and chronic effects of m-ethylphenol in both industrial settings and environmental outflows. Acute exposure typically brings respiratory irritation, headaches, and contact dermatitis. Over longer periods, some rodent studies suggest potential impacts on the central nervous system and organ function at elevated concentrations. Despite its value in manufacturing, m-ethylphenol’s ability to bioaccumulate in aquatic organisms stirs concern. Regulatory bodies call for continuous updates to permissible exposure limits and demand toxicological reevaluation as new data becomes available. On-site monitoring, employee training, and adoption of engineering controls offer the best defense against unexpected incidents.

The road ahead for m-ethylphenol reflects bigger trends in chemical production and sustainability. Efficient separation and greener methylation methods promise lower production costs and improved safety. Regulatory tightening on volatile organic compounds and waterborne contaminants applies pressure, but also spurs needed change in process design and waste handling. Markets show no signs of abandoning m-ethylphenol—demand grows for engineered resins, complex organic molecules, and fine fragrances. With more attention on renewables, engineered biosynthetic routes might grow into a commercial reality, making aromatic chemistry more sustainable for future generations.

M-Ethylphenol makes regular appearances in industrial chemistry, hiding behind more common neighbors like its cousins, ortho- and para-cresol. Chemists and industry pros often call it 3-Ethylphenol, owing to the position of its ethyl group on the benzene ring. This compound carries a sharp, phenolic smell and pops up most often as a colorless to pale yellow liquid. That odor alone tells anyone in the lab it belongs among a family of active, sometimes pungent, feedstocks.

Factories that build resins know M-Ethylphenol well. Phenolic resins rely on compounds like this for their heat resistance, electrical insulation, and strength. Sometimes, a tweak in the molecular mix improves resin flow or changes the final product’s flexibility. My experience in a small specialty coatings plant taught me that even a single percentage change in M-Ethylphenol makes certain lacquers easier to work with. These are not abstract details—a better resin recipe can mean safer circuit boards or stronger plywood.

Dyes and pigments call for phenolic compounds as building blocks. M-Ethylphenol lands right in the middle of this process. Color chemists use it for making intermediates that end up in printing inks or clothing dyes. The color-fastness of certain blues and reds owes a fair bit to this raw material. I’ve seen textile suppliers shift to products that use more reliable intermediates like M-Ethylphenol because mistakes in dye formulation show up as faded T-shirts or shoddy signage, embarrassing for both maker and customer.

Preservatives and disinfectants tap into M-Ethylphenol’s ability to break down cell walls. It shows up in several standard mixtures, especially those for industrial cleaning or tank sanitization, where bacteria and fungi can cause costly setbacks. Years ago, in a water treatment facility, I saw how switching to a stronger phenolic disinfectant helped curb biofilm clogs. That move cut maintenance in half for several months.

The pharmaceutical supply chain leans on it for specific API synthesis—sometimes as a starting point, sometimes as a modification tool for molecular tweaking. The FDA keeps an eye on any route that involves phenolic intermediates, so batch records and traceability stay ironclad. I remember a partner lab losing a lucrative contract when they let records slip. The importance of responsible handling and documentation can’t be overlooked with M-Ethylphenol, considering risks like irritation or, in rare instances, toxicity.

Production workers dealing with phenolic chemicals demand real PPE—gloves, goggles, and proper ventilation. I recall the sting of a careless splash during a late shift; no safety talk prepares you for a chemical burn that lingers for weeks. Proper containment, spill plans, and regular training make a huge difference in keeping teams safe.

Many regions regulate phenolic discharges closely, knowing these compounds can upset aquatic life. Factories invest in scrubbers and neutralization pits. It might sound obvious, but the cost of cleanup or fines from ignored oversight can wipe out a year’s profit.

Developers now look for ways to cut environmental impact. Some push into green chemistry—less waste, friendlier byproducts, and tighter recycling of spent phenols. These changes don’t just tick a compliance box; they keep local waterways cleaner and make neighborhoods less wary of industrial sites. Sustainable practices mean fewer accidents, easier permitting, and products that fit modern buyer expectations.

The first thing worth thinking about with M-Ethylphenol is its punchy character. This isn’t a substance to take lightly. Anyone who’s ever walked into a lab with an open container of M-Ethylphenol knows that sharp, almost medicinal scent. That bite to the nose does more than warn of a chemical—it tells you to keep your wits about you. Studies have pointed out its volatility and flammability. If spills or poor ventilation crop up, you risk more than an unpleasant workday; you’re playing with headaches, eye irritation, and sometimes a fire hazard.

Experience in busy labs underlines one thing: airtight containers matter. M-Ethylphenol doesn’t just linger in the air, it moves quickly and disappears if left out. Aromatic vapors build up quickly, and with a low flash point, one spark from an old electrical outlet or a careless lighter brings real trouble. Good practice means keeping bottles sealed, labeling everything properly, and never reusing old containers. It’s not just about regulatory paperwork—it’s about keeping operations safe and headaches at bay.

M-Ethylphenol demands a cool, dark home, away from heat or sunlight. It makes sense: sunlight can mess with chemical stability, and warmth pushes volatility higher. Throwing a flammable liquid near sources of ignition, even something as mundane as a break room toaster, risks disaster. In the labs I’ve worked in, flammable storage cabinets with grounded doors acted as the line of defense between normal operations and a risky situation. Don’t stash it near oxidizers, acids, or even strong bases. I remember a close call where stacking incompatible solvents led to a chemical reaction—quick thinking averted injury but left a lasting lesson.

Personal protective equipment isn’t a formality with M-Ethylphenol. Gloves, goggles, lab coats: they’re the front line. This isn’t just about avoiding stains on your clothes. Take it from an old lab tech who ignored a glove tear—skin contact burns. Splashes hurt eyes, vapor bothers lungs. Professional societies and chemical safety boards stress using nitrile gloves, not bare hands or thin disposable types. Chemical splash goggles, not cheap plastic face shields, stop rogue droplets. Every spill cleanup kit should include neutralizing agents and absorbent materials. Nobody ever forgot the day a spill kit lacked the right supplies; the downtime and paperwork alone set us back.

Even seasoned chemists benefit from regular reminders. New hires make mistakes—old hands pick up bad habits. Refresher training on safe handling often makes the difference between an average year and a major incident. Safety data sheets (SDS) can seem dense, but knowledge beats guesswork every time. Rolling eyes at repetitive training is common, but ask any safety officer, and they’ll tell you the same thing: consistent habits save lives.

Extra attention goes into handling chemicals like M-Ethylphenol because real-world consequences pile up quickly. It’s not about making life harder with more rules; it’s about working smarter. Investing in good storage cabinets and keeping up with training isn’t just bureaucracy. These are thoughtful steps rooted in stories, lessons learned, and a sometimes hard-earned respect for potent chemicals. Above all else, it’s a culture of responsibility—one that’s built by doing things right every single time.

Working with chemicals in labs or factories brings a long list of warnings, but M-Ethylphenol deserves a closer look. I’ve seen small mistakes go a long way, and this chemical proves unforgiving if handled carelessly. M-Ethylphenol gives off a strong odor that can fill a room quickly, making the first health threat pretty obvious—breathing in its vapor isn’t just uncomfortable; it upsets the central nervous system. Short exposure sometimes brings headaches, dizziness, or even nausea, but take in more, and the real trouble starts with coordination loss and trouble breathing.

Most folks worry about skin; M-Ethylphenol doesn’t waste time causing burns. Even through thin gloves, contact leads to redness, swelling, and painful irritation. Once, I watched a coworker shrug off a spill—within the hour, blisters were forming. Eyes stand little chance either. A small splash burns and blurs vision, with tearing and stinging lasting long after washing.

The danger creeps in with repeated exposure. A person may begin to notice skin getting dry, cracked, and more sensitive with every small accident. A study published in the International Journal of Occupational Medicine found regular contact raised the odds of dermatitis in chemical plant workers. Chronic inhalation can harm the liver and kidneys over months or years, giving organ health a slow beating that’s easy to ignore at first.

Big problems call for quick response, not panicking. If someone gets this on their skin, don’t waste minutes—strip off contaminated clothing and flush the area with lots of running water, not just a splash. Soap helps, but water comes first. I learned from experience that using hot water often worsens the problem; stick with cool, gentle streams.

Eye exposure means getting to a rinsing station fast; hold lids open and flush for at least fifteen minutes. Even if the pain fades early, keep rinsing—chemicals linger. Contact lenses just trap irritants, so get them out if you can. Afterward, get checked by a medical professional no matter how well you think you rinsed.

Inhaling vapors brings its own steps. Move to fresh air without delay. Let the person sit and breathe slowly; don’t force them to walk far until they feel better. If breathing problems begin—or the person passes out—call for emergency help right away.

Accidental ingestion seems unlikely, but paint-stained hands and a quick lunch add up to risk. If swallowed, never provoke vomiting. Give small sips of water if conscious, but skip milk or activated charcoal unless a doctor specifically says to use them.

Gloves and goggles sound basic, but they're crucial. Chemical splash goggles work better than plain safety glasses, and lab coats with snug cuffs act as the first barrier. Fume hoods and proper ventilation mean less vapor in breathing zones. I’ve noticed simple training makes all the difference—teach teams what to do before exposure occurs, not just after.

Chemicals like M-Ethylphenol shine a light on the gap between awareness and safety. Quick response works, but prevention wins the day. Organizations who enforce regular training and provide quality safety gear save people from regretful moments. Handling risks means remembering the basics and never letting routine dull respect for a chemical’s power.

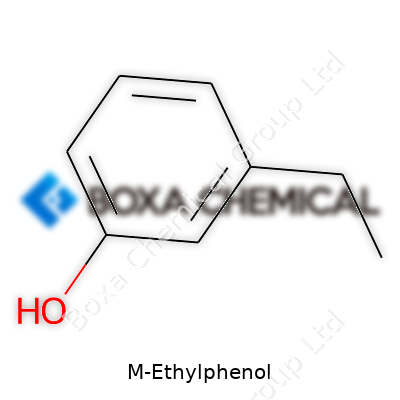

Chemistry unlocks a lot of mysteries in everyday life. M-Ethylphenol, also called 3-Methylphenol or meta-cresol, offers a good example of how a small change in a molecule’s structure can influence its features. The chemical formula for M-Ethylphenol is C7H8O. Its makeup includes a benzene ring, which is a hexagon of carbon atoms. A methyl group (CH3) connects to the third spot on the ring, and a hydroxyl group (OH) grabs position number one. So, you get a molecule that chemists often draw as a flat ring, with the methyl and hydroxyl decorations placed three carbons apart.

Looking closer, C7H8O tells you there are seven carbon atoms, eight hydrogen atoms, and a single oxygen. Each atom’s position shapes how this chemical acts with others. The systematic name, 3-methylphenol, points to the methyl group on the third carbon of the aromatic ring. The chemical’s structure makes it part of the larger phenol family.

During my time in a teaching lab, metacresol caught my eye for its distinct medicinal smell and its role in practical organic chemistry lessons. Teachers valued it when discussing antiseptics, because it’s not just about learning theory—students could actually observe its properties and chemical reactions. I remember a student accidentally using the wrong isomer and ending up with a product that missed the mark. It drove home how a single shift in a ring changes function dramatically.

M-Ethylphenol works behind the scenes in several industries. You’ll spot it helping to create antioxidants, resins, fragrances, and even preservatives. Disinfectant makers prefer it for strength and reliability. These uses depend on its unique family ties: the aromatic ring brings stability, while the methyl and hydroxyl groups boost activity. Its presence in creosote shows its place in wood preservation too.

Research over the years, published by organizations like the National Institutes of Health, links exposure to health risks if not handled properly. You want gloves and a fume hood on the job. Inhalation of vapors or skin contact irritates and poses longer-term threats if exposure climbs. Various safety datasheets point to its flammability and toxic nature in high concentrations. Knowing the molecular structure gives safety professionals a clearer guide on how to reduce harm.

Safer handling starts with clear labeling and education, not just for industry insiders but for anyone who may encounter it at work. Science keeps pushing for alternatives where toxicity outweighs benefit, and researchers work with green chemistry to design molecules with the same punch, minus the danger. My experience in research labs suggests that simple steps—like substituting safer reagents or limiting quantities—often pay off, but only if staff and students understand the “why” behind the structure.

In science, knowledge works best when it’s shared and discussed, not locked behind jargon. M-Ethylphenol’s molecular features shape its usefulness and its risks. Anyone working with it, whether in university or a factory, wins by treating chemical knowledge as more than lines on paper. Every atom counts.

Years working around chemicals taught me something simple: safety isn’t optional, and the real world punishes shortcuts. M-Ethylphenol shows up as a flammable, strong-smelling liquid. So, most companies use steel drums—usually 200 liters or thereabouts. I’ve helped set up shipments and watched crews check that the drums seal tightly and that gaskets don't show even the smallest wear. Polyethylene linings sometimes bolster the steel, keeping the product from gnawing at the metal. Smaller runs might arrive in high-density polyethylene bottles. Folks handling those rely on solid screw caps, shrink seals or even tear bands to fend off leaks.

A missed gasket or half-turn on a cap spells trouble—nobody enjoys walking into a warehouse hit by the scent of escaped alkylphenol. Even minor spills draw cleanup crews and fire marshals. So, real effort goes into triple-checking every closure and ensuring drums carry proper labels for contents, hazards, and regulatory info. Globally, those United Nations orange and black diamonds mean more than paperwork—customs won’t entertain unmarked drums. After incidents in an older plant, trucks leaving our lot always carried spill kits and visible hazard placards.

Supply chains use a mix of trucks, rail, and ocean freight. I’ve seen drivers get jumpy about alkylphenol drums. That’s based on harsh lessons—a bump or dropped drum can spark vapor releases. Crews use spill pallets and plastic wrap to keep things tight during travel. Specialized tank trucks handle large bulk transfers, but only with pressure relief systems and vapor return lines in place. In the past, missing even one hose meant trouble during off-loading, so training operators never gets shortchanged.

Rules from international bodies like the IMDG Code and US DOT dictate strict guidelines. Drivers must have clear paperwork, and every drum or tank sports a shipping manifest that spells out technical names, hazard classes, and emergency info. Enforcement isn’t gentle. I once saw a whole consignment turned away at a port due to faded hazard labels on just two drums.

Incidents with M-Ethylphenol usually tie back to human decisions, not the ingredient itself. Untrained staff, cost-cutting on containers, or missing signage causes more headaches than faulty equipment. Real transparency matters. Factories with a “don’t ask questions” mentality run into spills, fires, workplace injuries. After one local incident, our shop began linking bonuses to crew safety training and zero-leak records.

Technology nudges progress. Remote sensing tags now track drum movement and temperature. If a load gets too hot or tilts the wrong way, warehouse managers see alerts on their phones. I’ve seen insurance rates drop for companies with these trackers. The chemical world needs more of this open data flow, not less.

Every headline about chemical mishaps chips away at public trust. Neighbors see the fire trucks and wonder if their water supply is safe. In my experience, face-to-face talks with local responders and regular open-door days at the plant do more for real risk reduction than press releases. A shipment done right involves people watching out for one another, not just for the product in the drum.

| Names | |

| Preferred IUPAC name | 3-Ethylphenol |

| Other names |

3-Methylphenol m-Cresol m-Methylphenol |

| Pronunciation | /ɛm-ˈɛθɪlˌfiːnɒl/ |

| Identifiers | |

| CAS Number | 100-67-4 |

| Beilstein Reference | 636246 |

| ChEBI | CHEBI:77639 |

| ChEMBL | CHEMBL499 |

| ChemSpider | 67692 |

| DrugBank | DB14009 |

| ECHA InfoCard | 100.063.496 |

| EC Number | 203-585-2 |

| Gmelin Reference | 7416 |

| KEGG | C01575 |

| MeSH | D015555 |

| PubChem CID | 7309 |

| RTECS number | SJ3325000 |

| UNII | 7B94Q5SF1U |

| UN number | UN2529 |

| CompTox Dashboard (EPA) | DTXSID9044247 |

| Properties | |

| Chemical formula | C8H10O |

| Molar mass | 122.17 g/mol |

| Appearance | Clear colorless to pale yellow liquid |

| Odor | Phenolic |

| Density | 1.02 g/mL at 25 °C (lit.) |

| Solubility in water | slightly soluble |

| log P | 2.06 |

| Vapor pressure | 0.46 mmHg (25°C) |

| Acidity (pKa) | 10.1 |

| Basicity (pKb) | 10.7 |

| Magnetic susceptibility (χ) | -53.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.532 |

| Viscosity | 4.32 mPa·s (25 °C) |

| Dipole moment | 1.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 216.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -26.4 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3690.1 kJ/mol |

| Pharmacology | |

| ATC code | D02AE02 |

| Hazards | |

| GHS labelling | GHS02, GHS07, GHS08 |

| Pictograms | GHS02,GHS07 |

| Signal word | Danger |

| Hazard statements | H226, H302, H312, H315, H318, H332, H335 |

| Precautionary statements | P210, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | 81 °C |

| Autoignition temperature | 515 °C (959 °F; 788 K) |

| Explosive limits | 1.8–9.5% |

| Lethal dose or concentration | LD50 oral rat 820 mg/kg |

| LD50 (median dose) | LD50 (median dose): 620 mg/kg (rat, oral) |

| NIOSH | B203 |

| PEL (Permissible) | PEL: 5 ppm |

| REL (Recommended) | 0.5 mg/m³ |

| IDLH (Immediate danger) | 150 ppm |

| Related compounds | |

| Related compounds |

Cresol Phenol M-Xylene Ethylbenzene |