The story of m-cresol stretches back to the 19th century, tracing its roots to the expansion of coal tar chemistry. Early organic chemists recognized m-cresol’s presence as one of the three cresol isomers—along with o-cresol and p-cresol—isolated during the distillation of coal tar. The drive for synthetic dyes, antiseptics, and new materials pushed researchers to refine isolation and purification, shifting m-cresol production from unpredictable byproduct to targeted manufacture. By the 20th century, demand from the phenolic resin industry and pharmaceuticals powered broader applications, shifting industrial chemistry and carving a spot for cresols far beyond the laboratory bench. This evolution tells a story of industry’s push for reliable building blocks, never content to let the leftovers of coal tar distillation collect dust.

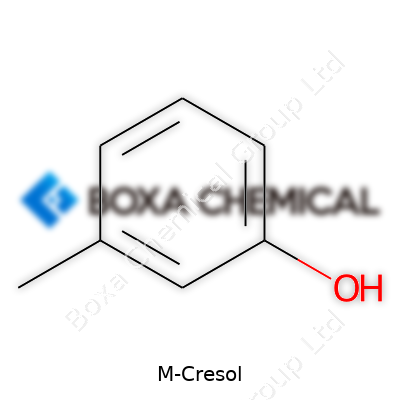

M-cresol, also known as 3-methylphenol, rides the line between specialty chemical and workhorse raw material. It shows up as a colorless to faint yellow liquid, developing a distinct medicinal smell that sticks around even with tight lids and careful handling. Today, you see m-cresol packed in steel drums or high-density polyethylene containers, ready for pharmaceutical labs or chemical plants. Distributors often flag its purity, with technical-grade and high-purity (above 99%) options available. The value grows whenever accuracy in chemical composition makes or breaks a process—pharmaceuticals, agrochemicals, resins, and antioxidants all lean on m-cresol for reliable synthesis work.

M-cresol melts at about 12°C and boils near 202°C, showing decent solubility in water. Its phenolic ring and methyl group supply both reactivity and resistance—making it suitable for substitution reactions while withstanding mild acids or bases. With a flash point around 86°C and vapor pressure that inches upward with temperature, workers need to pay attention to fire and inhalation risks. Density clocks in at about 1.03 g/cm³. The compound’s ability to mix with ether, ethanol, and chloroform gives it steady footing in countless reaction media. Corrosive nature and volatility call for safe storage, but these same traits help power its chemical versatility, letting it serve double duty as both solubilizer and reactant.

Labels for m-cresol bring transparency into handling and application. High-purity standards stress low levels of ortho- and para-cresol, low iron and non-volatile residue, and strict limits on water content. Chemical supply catalogs mark UN numbers, hazard symbols, and REACH compliance. Spec sheets often list acidity (in mg KOH/g), color (APHA), and major impurity thresholds. Shipment labels highlight toxicity and flammability. Safety Data Sheets (SDS) from major providers straightforwardly outline emergency responses, signaling a shift in recent decades toward worker protection and traceability over industrial expedience. Full documentation on batch purity and origin helps customers and regulators alike keep tabs on this headstrong chemical’s journey from plant to plant.

Coal tar distillation still provides some of the world’s m-cresol, but most producers favor the synthetic route. Alkylation of phenol with methanol using basic catalysts creates a controlled cresol mixture, which then runs through fractional distillation and sometimes further purification by crystallization or solvent extraction. Modern plants optimize reaction conditions for methylphenol yield, using catalysts like sodium hydroxide under high temperature and pressure. With advances in catalysis and process control, output quality has improved, while environmental regulations force plants to tackle waste by-products—limiting the spread of phenolic residues. These streamlined processes help ensure tight control over batch consistency and reduce the health risk and ecological footprint once rampant in earlier manufacturing eras.

M-cresol serves as a launching pad for downstream chemistry. Its phenolic function undergoes electrophilic substitution, allowing manufacturers to bolt on sulfonic, nitro, or halogen groups, pushing out intermediates for dyes or antiseptics. The methyl group resists oxidation but can convert—under tough conditions—into aldehyde or acid functions. Etherification and esterification with alcohols and acids expand m-cresol’s toolkit. Industrial chemists often run oxidative coupling or condensation reactions to build multi-ring phenolic resins, turning m-cresol into transparent plastics, laminates, circuit boards, or adhesives. These chemical transformations rarely occur in isolation; the compound’s reactivity weaves it into the fabric of modern synthetic chemistry.

Across catalogs and research reports, m-cresol appears under names like 3-methylphenol, meta-cresol, 3-hydroxytoluene, and, less commonly, m-toluol. Some pharmaceutical or electronic material producers use trade names, edge-marking specialty blends or high-purity grades to distinguish from generic stock. The proliferation of names mirrors m-cresol’s broad use and the drive by suppliers to stamp their product with an identity tailored to distinct markets. But underlying each naming convention, the foundation remains the well-characterized m-cresol molecule, keeping chemists aligned across borders and time zones.

M-cresol walks a tightrope between usefulness and risk. It acts as a potent irritant—skin, eyes, and lungs take hits on contact or inhalation. Prolonged exposure takes a toll on the central nervous system, liver, and kidneys. Chemical hygiene programs require protective gloves, goggles, and dedicated ventilation during transfer, mixing, or storage. Spill kits, fire extinguishers, and neutralizing agents need to be close at hand since vapors can ignite if conditions slip. Globally, agencies like OSHA, NIOSH, and ECHA set clear exposure limits: for example, 5 ppm as an 8-hour time-weighted average. Training matters here—I’ve seen facilities where routine practice lines up with safety codes, and the workers appreciate straightforward rules that keep accidents down. A culture built on clear protocols, accurate labeling, and regular review earns trust in the long run.

M-cresol keeps busy across sectors. Resin manufacturers depend on it for making phenolic and epoxy resins; these turn into brake pads, circuit boards, adhesives, and coatings. In the pharmaceutical field, m-cresol stabilizes formulations, acting as a preservative in insulin and vaccines. Agrochemical plants draw on its ability to synthesize herbicides and fungicides cost-effectively. Metal finishing operations reap antimicrobial benefits from cresol-based cleaners and disinfectants, though regulations limit concentrations. Dye and pigment makers borrow its backbone for color development. Over the years, I’ve seen safety and purity requirements intensify, especially in pharma—highlighting just how central m-cresol has become to both everyday products and critical medical supplies.

The research scene around m-cresol has seen remarkable transformation. Older studies centered on extraction, purification, and optimizing reaction efficiency. Today’s focus leans on green chemistry—developing catalytic systems that cut waste, energy consumption, and hazardous by-products. Newer projects examine m-cresol-based materials for use in high-performance coatings or medical devices, often leveraging its dual reactivity and biocidal nature. Analytical chemists work to improve detection and quantification, supporting forensic science and environmental monitoring. Nanotechnology and electronics researchers also push m-cresol as a building block for conductive polymers and advance materials that demand stringent purity and performance metrics. Open communication with regulators eases development cycles, as teams anticipate both performance and safety needs right from the outset.

Early toxicologists unearthed risks of m-cresol when researchers and workers developed dermatitis and respiratory effects. Laboratory studies on animals highlighted damage to organ systems, especially liver and kidneys, with oral or dermal exposure. Human case reports established acute poisoning risk during accidental ingestion or workplace mishaps. Modern toxicity studies now map out metabolic pathways, using precision biomarkers to spot low-level chronic exposure. Longitudinal data guide safer handling, pushing down workplace limits and steering industry toward ever-lower emission and exposure. Ecological studies confirm that m-cresol breaks down slowly in soil and water, affecting aquatic life—prompting tighter effluent controls. The challenge remains to balance utility with public and environmental health, requiring ongoing monitoring and innovation in detection, containment, and worker training.

Looking forward, m-cresol isn’t fading off the industrial radar. Demand stays strong in high-tech resins and next-generation medical preservative applications as those fields only grow more complex and regulated. Green chemistry stands out as a frontier, with ongoing investments into recyclable catalysts, water-based processes, and bio-based feedstocks that all promise to lighten m-cresol’s environmental load. Digital manufacturing and data-driven supply chain management help trace purity and safety, letting producers react faster to quality swings and regulatory shifts. Greater focus on exposure science and real-time detection could lower health risks further, helping industries keep pace with both productivity targets and rising safety expectations. Legacy and innovation now push chemical makers to aim higher both for efficiency and stewardship.

Walk down the drugstore aisle, and you may not spot m-cresol on any label, yet this simple-sounding chemical quietly shapes medical and industrial products many people use daily. I first heard of m-cresol through a conversation with a pharmacist friend. She mentioned it matter-of-factly, explaining its role in stabilizing some injectable medications, especially insulin. Turns out, m-cresol helps keep these formulas safe from bacteria until people are ready to use them.

That insight stuck with me, especially when news broke several years ago about insulin shortages. The key ingredients—including the preservatives—stood out as unsung heroes in getting people the medication they depend on. People whose lives rely on a steady supply of insulin trust that every shot stays safe and effective. Without a preservative like m-cresol, that reliability would crumble.

Looking outside healthcare, this chemical plays a role in some familiar, less obvious places. Manufacturers count on m-cresol to make antioxidants in lubricants and plastics. Mechanics and factory technicians see its value in prolonging machinery life, keeping engines running smoother through tough seasons. Companies also use it for synthesizing herbicides and disinfectants, helping keep farms and cities cleaner and less disease-prone.

I grew up on a farm where weed control kept crops healthy and yields predictable. Farmers and land managers know the value of chemical tools like those built with m-cresol. They make a tough job more manageable—not perfect, but certainly better than letting nature run unchecked and threaten months of hard work.

Every tool comes with trade-offs. M-cresol doesn’t fit easily on home kitchen shelves, and with good reason. Direct exposure can irritate skin, damage tissue, and even lead to more serious health problems through inhalation or absorption. Several workplace safety agencies, including OSHA and the European Chemicals Agency, outline safe handling rules for any factory or lab working with it.

Stories from the industry remind me that knowledge isn’t just for scientists. I remember hearing about an incident at a small manufacturing site where inadequate protective gear led to a worker’s hospital visit. Training, robust protocols, and protective clothing aren’t just boxes to check—they make a world of difference for people working around these substances every day.

The presence of m-cresol in so many fields doesn’t mean businesses or individuals should ignore risks. Solutions come from regular training and improved plant designs that minimize direct contact with harmful chemicals. Many companies invest in high-efficiency air filtration and spill containment. Mobile detection units and rapid response teams serve as early alarms to prevent minor exposure from turning into a health crisis.

Innovative chemists keep searching for new preservation methods in medicine, looking for alternatives that reduce potential side effects. The right balance means respecting the capabilities of m-cresol while working toward safer, cleaner options in the future. Each batch of insulin, each plastic part, every controlled weed—these owe a debt to clever chemistry and the people making it work in the real world.

M-cresol turns up in places nobody expects. Manufacturers use it to make preservatives, herbicides, and certain plastics. Some insulin solutions even include m-cresol as a stabilizer. The chemical smells sharp, like tar or medicinal oil, which isn’t surprising since it comes from coal tar or petroleum refining. People might run into m-cresol if they work in a lab, run certain industrial machinery, or take injectable medicines with this ingredient listed in the fine print.

Handling m-cresol without much care can be a rough lesson. I remember a colleague once brushed against a small spill on a lab bench. His skin stung, reddened, then peeled over the next few days. That episode stuck with everyone in the room and left behind a healthy sense of caution. Direct contact matters; m-cresol is corrosive and quickly damages skin and eyes. Even brief exposure through the air stings the nose and throat, and chronic inhalation may hit the nerves and lungs.

The data from studies back up these first-hand warnings. The Centers for Disease Control and Prevention (CDC) reports that people exposed to m-cresol in the workplace have faced headaches, dizziness, and trouble breathing. Severe cases linked to swallowing or large-scale skin exposure sent people to emergency rooms with burns, unconsciousness, and even kidney or liver problems. Everyone relaxes a little after hearing m-cresol evaporates fast, but evaporation spreads fumes, and those can build up if the room doesn’t breathe enough.

Health isn’t just the job of scientists in white coats. Parents at home, workers stocking shelves, people giving themselves injected medicine—so many rely on trust. Trust in industry, in regulators, and in labels that don’t hide nasty surprises. M-cresol, used carelessly, turns that trust on its head.

Take, for example, the community clusters near big chemical plants, where m-cresol appears in air or drinking water after a spill. People living nearby reported more breathing problems and skin issues. Environmental Protection Agency (EPA) tests keep a close watch, but resources run thin, and families sometimes spend weeks waiting for clean-up or for straight answers.

Practical safeguards work better than panicked warnings. Wearing sturdy gloves, real safety goggles, and using chemical fume hoods lets workers handle m-cresol without drama. Regular training, spill kits, and solid reporting systems stop accidents before they grow into headlines. At home, folks using insulin that contains m-cresol should never improvise with container swaps or expired medicine. Each new syringe or vial must stay sealed and stored the way pharmacists say.

Health regulators can help most by ensuring factories report how much m-cresol they release. Local health departments must keep lines open so people can ask questions and get straight talk, not just legal disclosures. Companies should invest in better air monitoring and waste treatment so that communities don’t wake up coughing or end up on bottled water after every heavy rainstorm.

Most risks tied to m-cresol come from carelessness or from not knowing what’s in that strangely labeled drum in the corner. Honest labeling, modern safety gear, and constant info-sharing take away much of the danger. With some effort, communities and industries can keep both the jobs and safety that everyone deserves.

M-Cresol stands out as a crucial compound for anyone working in chemistry, pharmaceuticals, and even some industrial manufacturing. Its chemical formula is C7H8O. That simple string of letters and numbers unlocks a lot of information, especially if you find yourself concerned with the safety, function, or environmental impact of certain chemicals.

A few years ago, during a project involving antiseptics, I kept running into cresols as ingredients. Many people, including some colleagues, didn’t look beyond the name on the bottle or the SDS sheet. The formula—C7H8O—makes it instantly clear that m-cresol is a methylated phenol, so it’s both an aromatic ring and has that well-known OH group that marks phenols. That’s the core reason why it acts as an antimicrobial: the hydroxyl group disrupts cell membranes in bacteria.

It’s not just microbiology that gets impacted. Factories use m-cresol in resins, herbicides, and even the production of vitamin E. Knowing its formula, you can work out potential byproducts, check for hazardous reactions, and decide the best type of storage. If you understand those seven carbons arranged in a ring, with one methyl group and one hydroxyl on adjacent positions, handling the substance makes more sense. People have faced accidents or product recalls because they didn’t check physical and chemical properties tied to the formula.

Every time a debate on chemical safety pops up, m-cresol’s formula creeps into the discussion. C7H8O tells you about its volatility and why it’s hazardous if inhaled or spilled; it evaporates quickly, and that aromatic ring structure adds toxicity. Decades of studies show cresols can irritate the skin, respiratory tract, and eyes, and they carry some risk of long-term toxicity. Because of this, regulators like OSHA and EPA have poured years into setting limits for exposure.

People still occasionally underestimate cresols, either by amateur use in cleaning products or in agricultural pesticides. I remember seeing a case at a local farm, where workers weren’t told what was in a particularly strong herbicide solution. The result? A set of unnecessary hospital visits that could have been avoided if the staff had proper labeling, explained the chemistry, and clarified what C7H8O actually means for everyday work.

Talking with industry veterans reminds me that chemical education doesn’t just belong in the classroom. By spelling out formulas, proper storage protocols, and health impacts in plain language, everyone from a farmer to a chemical engineer stands a better chance of making good decisions.

One practical move is better training for people handling cresol-based chemicals. Labels should put the formula up front and pair it with real-world advice, not just technical warnings or jargon-filled data sheets. Technologies like digital inventory tools could flag substances based on their formula and cross-check their compatibility with others, giving an extra layer of safety.

A compound like m-cresol isn’t just a lab curiosity. Its formula—C7H8O—serves as both a warning and a guide. It’s a small string that packs a punch, shaping decisions in health, safety, production, and research. Knowing it, applying it, and honoring what it means can prevent tragedy and lead to smarter questions at every step.

M-Cresol pops up in plenty of places, from making resins and plastics to acting as a preservative in some medicines. It helps with real problems, but it packs a punch when it comes to health risks. Get a little on your hands, and the burn reminds you why caution comes first. Breathing in vapors can irritate the lungs or worse. For anyone working around chemicals, M-Cresol commands respect and clear protocols.

Good storage makes all the difference with this chemical. Letting it sit in thin plastic containers, shoved in the back of a storeroom, only asks for trouble. The best practice uses tightly sealed glass or stainless steel containers. Proper labeling stands out as more than a rule—it keeps coworkers from accidental contact or using the wrong material in a hurry. Temperature matters too. Heat spikes lead to pressure buildup, so a cool and dry place away from direct sunlight works best. It helps to add clear signs and set that space aside just for chemicals like M-Cresol.

Spills once left stains on my steel-toed boots after an old coworker ignored the guidelines and used a cracked jug. The mess called for a full shutdown while everyone grabbed gloves and goggles. Accidents like that eat into productivity and morale. Good storage won’t guarantee perfection, but it stops most emergencies before they start.

No one likes putting on itchy gloves and snug goggles, but dealing with burns or a trip to the hospital proves far worse. Nitrile gloves hold up well against M-Cresol, along with a long-sleeved lab coat. Splash-proof goggles do more than earn a checkmark—they stop the stinging and scarring that comes from hurried mistakes. Working under a fume hood knocks out harmful vapors, keeping headaches and respiratory issues off the list. Clear, written steps posted nearby help everyone remember what matters when opening, pouring, or transferring the chemical.

Skin burns, headaches, and even long-term harm to liver and kidneys show the need for constant care. Long exposure to vapors or droplets causes harm before most people realize it. Secure storage and sensible handling lower these dangers to almost zero. For those managing a site or lab, routine training and practice drills build habits that last.

Routine inspections matter. Checking seals, storage temperatures, and expiration dates helps find problems before someone tries to fix a leak on the fly. Spill kits near the storage area save time when someone tips a container. Clear recordkeeping means everyone knows who used what and when, lowering the risk of mistakes. Good ventilation—simple fans or full fume hoods—reduce vapor build-up.

Storage and handling of M-Cresol can be tackled without high-priced technology. Attention to detail, the right protective gear, and routine safety checks give peace of mind and cut down on scary accidents. It all boils down to habit. Build a routine, stick to it, and serious incidents become rare instead of routine.

M-Cresol serves plenty of purposes in labs and industry. Folks mix it into resins, carve it into disinfectants, even use it to preserve certain pharmaceuticals. Don’t let that everyday presence fool you—it packs more punch than most household chemicals. One drop can irritate skin, sting eyes, and, when inhaled, burn the lungs. Over time or with enough exposure, it can cause headaches and kidney stress, with little warning. These risks don’t just exist on paper; even trained workers who ease up on safety practices regret lapses pretty fast.

My own experience in chemistry research drilled one habit above the rest—personal protective equipment comes out first, every time. Gloves, splash goggles, and a sturdy lab coat mean the stuff won’t get straight to your skin or eyes. Thin, single-use gloves melt fast with solvents like M-Cresol, so only thick, chemical-resistant gloves do the trick. Most folks don’t realize latex or vinyl often disintegrate during longer contact. Bringing a full-face shield makes even more sense if spills or fume bursts are possible.

A good lab fume hood pulls away fumes before anyone breathes them in. Relying on open windows or fans misses the mark. Direct inhalation won’t just mean coughs—in higher doses, cresols have put people in the hospital. Respirators rated for organic vapors add another level for workers who can’t avoid fumes.

M-Cresol does fine in a cool, dry cupboard away from strong acids and metal powders. What does trouble starts with weak seals or makeshift containers. It can eat through some plastics, so only glass or certain heavy-duty plastics with airtight seals belong in the storage room. Labels need clear, rugged writing—no faded sharpie or peeling stickers—so even a drowsy coworker at midnight can spot what’s inside. The only mishap I’ve ever had with cresols came from a mislabel, not from the user but the last shift’s rush.

For a spill, no one should go solo. Training means teammates know who fetches the absorbent pads, who blocks off the area, and who calls for help if it splashes onto skin or in the eyes. Every high school lab has an eyewash, but I’ve seen labs stash cresol far from working sinks. Any contact with skin or eyes asks for fifteen minutes flushing, not just a quick rinse—and people often stop too soon.

Ventilating an area after a spill keeps headaches and breathing trouble from coming on, even if all liquid gets mopped up. Used gloves, pads, or contaminated lab coats need designated, closed disposal bins—municipal waste won’t cut it because cresols linger and can seep out over time.

Most safety breakdowns don’t start with reckless behavior but with regulars who “have done it a hundred times.” Nobody likes to sit through another safety review, but those run-throughs transform theory into habit. Newcomers shadowing a careful veteran pick up quick tricks—like setting out spill kits before opening containers or wet-wiping counters for stray drops. Safety rules stick when they’re shared, rehearsed, and reinforced by experience instead of just tacked to a bulletin board.

Mistakes happen less when everyone—from new hires to chiefs—calls out shortcuts or missing gear on the spot. Rounds of outside safety audits help too, not as inspections to dread, but as chances to spot worn gloves, expired eyewash bottles, or cluttered exit paths.

Taking care with M-Cresol never feels optional for anyone who’s seen what it can do. Mixing good habits, solid gear, fresh labels, and honest training goes further than any warning label to keep people healthy and work safe.

| Names | |

| Preferred IUPAC name | 3-methylphenol |

| Other names |

3-Methylphenol meta-Cresol m-Cresylic acid 3-Hydroxytoluene m-Hydroxytoluene |

| Pronunciation | /ˈɛmˈkriːsɒl/ |

| Identifiers | |

| CAS Number | 108-39-4 |

| Beilstein Reference | 1209229 |

| ChEBI | CHEBI:17250 |

| ChEMBL | CHEMBL1409 |

| ChemSpider | 5349 |

| DrugBank | DB11345 |

| ECHA InfoCard | 100.011.521 |

| EC Number | 200-39-6 |

| Gmelin Reference | Gmelin Reference: **83215** |

| KEGG | C01444 |

| MeSH | D003436 |

| PubChem CID | 780 |

| RTECS number | GO6430000 |

| UNII | Y3632606TY |

| UN number | UN2076 |

| Properties | |

| Chemical formula | C7H8O |

| Molar mass | 108.14 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | sweet, tarry, phenolic |

| Density | 1.034 g/cm³ |

| Solubility in water | slightly soluble |

| log P | 1.98 |

| Vapor pressure | 0.11 mmHg (25°C) |

| Acidity (pKa) | 10.09 |

| Basicity (pKb) | 10.21 |

| Magnetic susceptibility (χ) | -7.72e-6 cm³/mol |

| Refractive index (nD) | 1.546 |

| Viscosity | 11 mPa·s (25 °C) |

| Dipole moment | 1.26 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 96.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −26.8 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -3523 kJ/mol |

| Pharmacology | |

| ATC code | D08AE03 |

| Hazards | |

| Main hazards | Toxic if swallowed, toxic in contact with skin, causes severe skin burns and eye damage, toxic to aquatic life. |

| GHS labelling | GHS02, GHS05, GHS06, GHS08 |

| Pictograms | GHS02,GHS06 |

| Signal word | Danger |

| Hazard statements | H226, H301, H311, H314, H331 |

| Precautionary statements | P261, P264, P270, P271, P273, P280, P301+P310, P302+P352, P304+P340, P305+P351+P338, P310, P321, P330, P362+P364, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-0 |

| Flash point | 88 °C |

| Autoignition temperature | 540 °C (1004 °F; 813 K) |

| Explosive limits | Explosive limits: 1.3% to 7% (in air) |

| Lethal dose or concentration | LD50 oral rat 242 mg/kg |

| LD50 (median dose) | LD50 (median dose): 200 mg/kg (oral, rat) |

| NIOSH | K0347 |

| PEL (Permissible) | 22 mg/m³ |

| REL (Recommended) | 20 mg/m³ |

| IDLH (Immediate danger) | 250 ppm |

| Related compounds | |

| Related compounds |

Phenol o-Cresol p-Cresol Thymol Xylenol Cresolsulfonic acid |