Chlorophenol has a deeply rooted history that goes back to the late 1800s, a period marked by rapid industrial growth and early discoveries in organic chemistry. Early researchers pushed hard to understand how chlorine interacted with phenols and other aromatic compounds, often motivated by a need for better wood preservatives and disinfectants. By the 1930s and 1940s, the growth in pesticides and antiseptics helped push chlorophenol into broader industrial use, especially in timber and leather sectors. The growing realization of its environmental footprint, thanks to pioneering toxicity studies, forced industries to rethink methods and uses through the following decades.

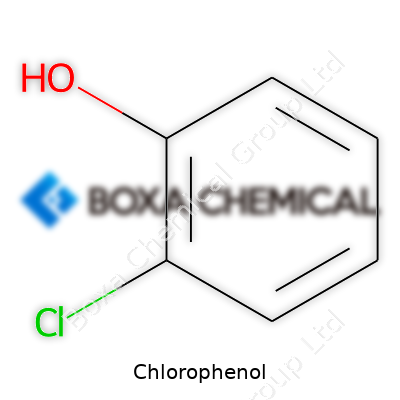

Chlorophenol isn’t just a single compound—it represents a whole family of chemicals. These include monochlorophenols, dichlorophenols, trichlorophenols, and even pentachlorophenol. Each member of this group comes with its own set of uses and hazards. The differences stem from the number and placement of chlorine atoms around the phenol ring. In the real world, trade names and synonyms like Dowicide, Santophen, or Penta keep popping up, which can muddy regulations or shipment labeling if you’re not careful.

Unlike many other bulk chemicals, chlorophenols often stand out because of their sharp, medicinal odor. You’ll find them as colorless crystals or yellowish solids, depending on the specific type and purity. Most dissolve easily in organic solvents like ethanol or diethyl ether but only mix slightly with water unless the temperature is boosted. Chemically, adding chlorine atoms makes these compounds harder to break down. That’s a gift for long-term industrial processes but trouble for environmental safety. Their melting and boiling points tend to rise with more chlorine atoms on the ring.

In plant environments, keeping quality consistent is a tough job. Chlorophenol’s technical specs cover purity (often above 99%), specific gravity, and color index. Labels look complicated but, in my experience, the most important things to get right are the UN/NA shipping numbers, hazard diamond, and CAS number, which prevent confusion when shipping or responding to a safety incident. For pentachlorophenol, even small batch differences can show up as crystal shape or smell—a headache for those evaluating product quality in the warehouse.

Manufacturers make chlorophenol by introducing chlorine gas or other chlorinating agents like sodium hypochlorite to phenol, all under controlled conditions of pressure and temperature. Sometimes the reaction takes place with a catalyst, often iron or sometimes aluminum chloride, to control where the chlorine ends up on the ring. The specific solvents, temperature, and time settings often become trade secrets. In small labs, the method is straightforward. On a plant scale, designers wrestle with corrosion, gas handling, and purification of end products to keep up with both local and international standards.

Chlorophenol exhibits a pretty active chemistry. It reacts with bases to make phenolate salts, which help extract or clean up spills in industry. It can serve as a foundation for more complex molecules after modifications, usually through etherification or nitration reactions, turning it into something like herbicides or dyes. Heating or subjecting to UV exposure can promote further breakdown—sometimes good, sometimes leading to persistent environmental problems. This chemical's role as a precursor in syntheses matters for those in agrochemical or pharmaceutical manufacturing.

If you’ve bought or sold industrial chemicals, you know how quickly synonyms become confusing. 2-Chlorophenol is called o-chlorophenol, and there’s also 4-chlorophenol or p-chlorophenol. For bulk shipments, the full IUPAC name usually goes on documents. In older warehouses, labels stuck with trade names: Dowicide 1, Santophen 20, or Termiticide, depending on the sector. International commerce managed to bring some clarity with registries, but local habits in naming still trip people up in the field.

Dealing with chlorophenol in a lab or production facility keeps safety managers on their toes. Prolonged exposure brings up skin, eye, and lung irritation risks. Chronic exposure or spills, especially with pentachlorophenol, links directly to organ damage and increased cancer risk, according to EPA assessments and IARC monographs. Protective gear—full-face respirators, gloves, and chemical suits—are non-negotiable in any plant handling more than a few kilograms. Local exhaust ventilation and regular medical checks for workers keep operations safer. Regulations under the OSHA Hazard Communication Standard and EU REACH ensure emergency services and workers get real training, not just a checklist.

Timber preservation dominates chlorophenol’s industrial history, especially in North America and Europe. Utility poles, railroad ties, and marine timbers soaked up pentachlorophenol to fend off fungi and termites. You’ll see traces in old water treatment plants, leather tanning, and specialized herbicides. Smaller volumes end up in laboratories looking to synthesize new pharmaceuticals or conduct scholastic toxicology experiments. The tide shifted after 1980, as new pest resistance and a better understanding of toxicity pressures began shifting the focus toward less persistent products.

Research carried out after the widespread uses of chlorophenol turned up plenty of unintended problems. Labs started developing better degradation techniques, like advanced oxidation, to fix contaminated soil and water. For those inside university research communities, figuring out safe and economically viable alternatives brought together chemists, ecologists, and safety experts. Most industrial labs now try to optimize synthesis for selectivity, cutting down on hazardous byproducts and shrinking waste streams. Public health advocates keep pushing for more transparent environmental monitoring and product lifecycle tracking.

Long-term health studies showed that chlorophenol doesn’t just cause temporary irritation. Researchers tracked links between occupational exposure and increased cancer rates, especially in workers handling pentachlorophenol. Environmental scientists keep reporting on its stubbornness in groundwater, leading to contamination fears in both urban and farm communities. The EPA has flagged several members of the chlorophenol family as persistent bioaccumulative toxins (PBTs), leading to tough limits in both discharge permits and end-of-life product disposal.

As companies face tighter regulations and growing public worries about chemical safety, the role of chlorophenol will keep evolving. Ongoing innovation focuses on finding less toxic, biodegradable alternatives for timber and leather treatments. The next generation of manufacturing methods aims for cleaner, more energy-efficient processes, cutting the footprint that kept growing for over a century. Advanced monitoring of groundwater and air quality promises to bring past abuses out in the open and help clean up legacy sites. For future uses, the shift leans toward tightly regulated specialty chemistry, away from widespread bulk application. Experience shows that greener, safer materials aren’t just possible—they’re now market expectations for anyone hoping to stay relevant in a changing industry.

Chlorophenol doesn’t always get headlines, but this chemical pops up in more daily products and industries than most realize. The simple act of flipping on a light or opening a medicine cabinet brings us into contact with products where manufacturers rely on this compound. Chlorophenols come in several forms, depending on how many chlorine atoms hook onto a phenol ring. This slight change in chemistry means it can do a lot—the reason so many companies find value in it.

Walk through a hardware store and the scent of fresh cut lumber greets you. Preserving that wood against rot, mold, and bugs remains a challenge. Chlorophenol steps in as one of the agents that keep telephone poles, railroad ties, and fenceposts out in the elements longer. It doesn’t only protect wood—the same ability to destroy bacteria, fungi, and pests makes it a regular pick for disinfectants and antiseptics.

Hospitals rely on strong disinfectants. Surgeons want a clean environment to cut infection risk. Chlorophenol formulas, especially those called “chloroxylenol” or “PCMX,” land in surgical soaps, surface sprays, and even some wound cleaners. At home, products like certain antibacterial soaps and household cleaners contain related ingredients.

Beyond keeping buildings safe and people healthy, chlorophenol works as a building block in chemical manufacturing. Factories use it to create pesticides, dyes, and even drugs. For example, I’ve noticed that over-the-counter throat lozenges, anesthetic sprays, and topical medications often list derivatives of chlorophenol on their labels. In agriculture, these chemicals help fight blight and pests on crops, which means grocery stores can offer bigger yields without all produce going bad.

Nobody wants harmful byproducts in drinking water or the air. Because of its strength, chlorophenol can pose real risks if released into the environment. Workers processing wood or working in certain plants report headaches or irritation when exposed to the fumes. Long-term exposure, especially at high levels, can even affect organs. Recent studies show links to breathing issues, skin irritation, and some increased cancer risks with chronic exposure. Waste streams from plants that treat wood or produce pesticides have, in the past, led to contaminated soil or waterways.

Cleanup remains tough. Chlorophenol doesn’t break down easily under sunlight or bacteria. Regulations in countries like the US and UK set strict limits on how much can enter the air, water, or finished products. The EPA and other watchdogs demand control systems and regular checks.

Responsible use of chlorophenol comes down to two efforts: better handling and exploring alternatives. Workers in industries that use these chemicals depend on protective gear, good ventilation, and waste capture systems. Tech advances now bring safer options for many uses—some companies have switched to alternative preservatives, like copper or organic compounds, especially for indoor applications. Shoppers looking for “green” cleaning and garden products have broader choices than a decade ago, and stricter labeling on most over-the-counter products adds transparency.

Chlorophenol isn’t going away soon. Its efficacy, history, and cost keep it in use. Yet research and innovation continue, pressuring producers to find safer, smarter ways to achieve the same goals. Understanding what’s in our products helps push the conversation forward.

People rarely think about what happens after cleaning the kitchen or using disinfectants. Chlorophenol, found in some cleaning products, preservatives, and pesticides, often slips under the radar. It seems helpful at first glance, but the real story unfolds in small print: this chemical carries risks most people don’t recognize. My years working in environmental journalism taught me to question the safety of everyday substances, especially those that linger in air, water, and even food.

Skin contact with chlorophenol brings a fast response—irritation, redness, maybe even a burn with higher concentrations. I once spoke with a worker from a wood-treatment plant who described skin blistering and an odd, sharp smell that stuck to his clothes. Inhaling the vapor or dust may provoke headaches, dizziness, and a foul taste in the mouth. At higher exposure, nausea and vomiting kick in, sometimes making small tasks unbearable. Medical case studies echo the same symptoms, as emergency rooms have seen industrial workers stumble in after prolonged chemical contact.

The real trouble comes from slow buildup. Chlorophenol breaks down slowly in the environment and the human body. Repeated exposure—breathing contaminated dust, drinking polluted water, or handling tainted materials—lets the chemical accumulate in fatty tissue. Over time, people start to notice symptoms that mimic chronic illness: fatigue, joint pain, and sometimes even changes in liver function. This stuff doesn’t just pass through and disappear; it leaves a mark that can last for years.

Research links chlorophenol to more than just short-term illnesses. Scientists have reported a higher cancer rate in people with regular, long-term exposure. The World Health Organization flags certain types of chlorophenols as possible human carcinogens. Animal studies hint at links to immune suppression and hormone disruption. Data pulled from communities living near sawmills and waste sites add to the worry, connecting groundwater contamination with higher reports of illness. This evidence kicks up concerns beyond basic allergies or irritation—it’s about real, life-changing health impacts across generations.

People have options to steer clear of chlorophenol. Reading product labels and swapping cleaners for less hazardous alternatives cuts risk at home. Workplaces that still use this chemical must give staff protective gear and solid training. Installing proper ventilation keeps fumes out of lungs, while regular monitoring of water and work surfaces catches contamination before it becomes a widespread problem. On a broader scale, supporting stricter regulation and pushing companies toward safer preservatives moves the needle over the long term. The EPA and similar agencies have started tightening rules, but action from everyday people helps push those efforts further.

Stories like these always remind me to look past marketing claims and dig into the facts. Chlorophenol isn't just a technical word—it's a real threat in certain doses or situations, demanding smart choices from both consumers and industry leaders. Watching out for this chemical helps safeguard families, workers, and future generations from its hidden health risks.

Chlorophenol doesn’t belong on a regular shelf in the back of the janitor’s closet. It helps kill bacteria and fungi, finds its way into disinfectants, and even lends a hand in chemical manufacturing. The trouble starts when its risks get overlooked. Breathing its vapors can cause headaches, dizziness, and lung problems. Skin exposure leads to irritation or burns. Over time, poor handling and careless storage cause fires, health problems, and hefty cleanup bills.

Growing up in a rural town, I saw how “just leave it in the shed” thinking put people in danger. Once, a leaking bottle gave off strong medicinal smells for weeks, nobody realized the risks until someone ended up coughing near the door. The lesson stuck with me: no chemical, especially one as strong as chlorophenol, should get the casual treatment.

The rules aren’t just red tape. There’s real science behind safe chemical storage. Keep chlorophenol in tightly sealed glass or high-density polyethylene containers. Ordinary plastic might turn brittle or leak over time, so it pays to check every container for signs of damage. Never use recycled food containers or anything not made for chemicals.

A locked, ventilated room works better than an open shelf in a warm warehouse. Chlorophenol releases toxic vapors if it heats up or sits in the sunlight. Inhaling these fumes can put workers at risk. Vents should pull fumes outside, not just circulate them in the room.

Temperature makes a difference. Store chlorophenol somewhere cool and dry. Moisture can react with the chemical, creating stronger fumes or even corrosion on metal shelves. Fire risk climbs if the storage gets too warm. Install temperature alarms, and check them regularly.

Fires caused by poorly stored chemicals spread quickly. Keep chlorophenol away from open flames, sparks, and oxidizers. Metal shelving without drip pans creates a perfect storm for spills, so invest in chemical-rated shelves with built-in containment. Ground every container to prevent static electricity—the shock you barely feel can ignite fumes.

In my first job at a hardware store, a small bottle of solvent leaked onto an overloaded power strip. That mess could’ve started a serious fire. Chlorophenol demands more respect.

Have fire extinguishers designed for chemical fires, not just general ones. Place spill kits and absorbent materials nearby. Post clear safety signs where everyone can see them—the kind that uses words people understand, not just tiny hazard symbols.

Even the best storage won’t work if people skip steps or ignore problems. Regular safety drills help workers spot trouble. Supervisors should walk the storage area often and fix any leaks or damaged containers.

Keep a written log of what comes in and out. Real accountability means everyone signs off. If your business stores chlorophenol, teach every worker to read the label and follow handling instructions. Don’t assume people know what “hazardous” really means.

Good habits prevent disaster. The more people respect the dangers, the fewer health scares or emergencies show up down the line. Chlorophenol isn’t something you hide out of sight and forget— you secure it, watch it, and treat it with the caution it demands.

Anyone who grows up near old factories or rail yards probably has stories about strange-smelling water or dead fish floating in rivers after a heavy rain. Chlorophenol sits behind some of these memories. For years, it has punched its way into rivers and soil from leaking drums, discarded wood treatment, and old industrial sites without many folks thinking twice. That habit left a heavy mark on ground and water.

Chlorophenol breaks down slowly in nature. That’s a problem for fish, frogs, and even insects whose lives begin beneath the surface. When chlorophenol leaks into waterways, fish struggle to breathe and spawn. I once saw a creek where minnows washed up gray and still after a rainstorm carried runoff from a nearby lumber yard. The scientific consensus backs up those eyes: studies show chlorophenol damages fish gills and disrupts their hormones.

Plants do not stand a chance when soil picks up too much chlorophenol. Crops in contaminated fields take on stress, yellow, and sometimes fail outright. The soil’s tiny workers—bacteria and worms—also take a hit. With less life in the dirt, soil becomes crusty and less fertile. Over time, this builds up, leading to fields that yield less and struggle to bounce back. The U.S. Environmental Protection Agency points to legacy lumber and chemical manufacturing as sources of this quiet problem.

Not every problem lies hidden underfoot. Anyone who’s walked near an improper dump or an old, treated wood plant will tell you about the chemical tang in the air. Chlorophenol doesn’t just stay put; it evaporates and moves downwind. Short bursts can annoy your nose, sting your eyes, or give headaches. For communities near legacy dump sites, it hangs around and affects daily life and the ability to enjoy outdoor spaces.

Chlorophenol isn’t just a problem for biologists or folks who test water. Once chlorophenol gets loose, it sneaks onto dinner plates through contaminated crops or fish. People facing long-term exposure run higher risks for certain cancers and liver damage, especially kids. Thinking of my own backyard garden, I’d never want to wonder if my tomatoes soaked up something toxic from the ground.

Better monitoring makes a difference. Agencies can test river sediments, city water intakes, and schoolyards near old industrial sites. Some towns made good progress by removing contaminated soil, replacing it with clean fill, or building lined ponds to trap runoff. Local activists often push hardest for this work, as I’ve seen in towns along the Ohio River. They knock on doors, organize river cleanups, and press city hall to keep safety checks honest.

Banning certain applications matters too. Many countries already block the use of chlorophenols in household disinfectants and wood preservatives. Industry needs clear rules and strong fines to keep these chemicals where they belong, which means sealed, audited storage or proper hazardous waste facilities. Regular community meetings create the space for neighbors to speak up if something smells or looks off.

We all share a stake in cleaner water, better crops, and air not tainted with decades-old chemical mistakes. By keeping the conversation honest, staying vigilant, and pushing for sensible laws, people can make a dent in the damage chlorophenol leaves behind.

Chlorophenol turns up in places that most people will never see—industrial plants, power stations, and old pesticide drums. This chemical stays stubborn in the environment and causes real trouble, from fish kills in rivers to breathing problems in workers who handle it without protection. Keeping chlorophenol out of the water supply means communities keep their drinking water safer and people stay healthier.

Many of us remember labs in school with their sharp chemical smell. Now imagine gallons instead of grams. Chlorophenol spills can spread fast and soak into the ground, and groundwater doesn’t have a reset button. Any effective disposal plan puts safety upfront. Full-face respirators, chemical gloves, and no shortcuts give people a better chance of getting home healthy. Splash goggles and well-ventilated spaces aren’t optional—they are the difference between safe handling and a crisis.

Commercial high-temperature incineration breaks apart chlorophenol molecules in a way that simple burning at low heat can’t touch. A proper hazardous-waste incinerator hits temperatures above 1,100°C. At that heat, even stubborn chlorinated molecules split down to safer parts. But smoke stacks and ash need checking for pollutants before leaving the facility. Dioxins form if a furnace runs too cool or if filters get neglected. Good oversight and reliable permits matter here much more than any shiny brochure promises.

Some plants use chemical treatments—think sodium hydroxide mixed with chlorine—to break down chlorophenol. This approach requires experience. Get the ratios wrong and toxic byproducts pop up. Wastewater experts stress that timing and agitation affect what forms at the end, so hands-on knowledge carries weight. Landfill disposal has fallen out of favor: this chemical sticks around for decades, seeping outward. As a worker at a remediation site, I’ve seen how containment “fails” and monitoring wells light up with warning signs months after the last load gets dumped.

Regulators put weight on cradle-to-grave tracking of hazardous waste. Documentation, sealed containers, and copy-after-copy of manifests hold people accountable. Digital tracking can speed response if something goes wrong, though smaller sites still lean on paper. It helps when plant managers open lines of communication with waste companies and local emergency staff. If a spill happens, calling for public notice—not hoping nobody notices—builds more trust and helps catch issues early. Training updates push standards higher, and seasoned workers can help newcomers avoid simple but serious mistakes.

Chlorophenol doesn’t forgive lazy disposal. One shortcut can leave a community’s well water unusable for generations. Disposing of chemicals safely costs time and money, but those costs stack up much slower than cleanup, legal battles, and lost health. People who do this work well keep disasters off the front page—sometimes their quiet care shapes better outcomes than any headline ever will.

| Names | |

| Preferred IUPAC name | Chlorophenol |

| Other names |

para-chlorophenol p-chlorophenol 4-chlorophenol p-chlorohydroxybenzene 4-hydroxychlorobenzene |

| Pronunciation | /ˌklɔːr.əˈfiː.nɒl/ |

| Identifiers | |

| CAS Number | 95-57-8 |

| Beilstein Reference | 1329379 |

| ChEBI | CHEBI:27314 |

| ChEMBL | CHEMBL84941 |

| ChemSpider | 23478 |

| DrugBank | DB11367 |

| ECHA InfoCard | 100.003.263 |

| EC Number | 1.11.1.7 |

| Gmelin Reference | Gmelin Reference: 804 |

| KEGG | C01444 |

| MeSH | D002704 |

| PubChem CID | 8449 |

| RTECS number | SN4300000 |

| UNII | P34DQ6J2FW |

| UN number | UN2021 |

| Properties | |

| Chemical formula | C6H5ClO |

| Molar mass | 128.56 g/mol |

| Appearance | Colorless to pale pink crystalline solid |

| Odor | Strong, penetrating, aromatic odor |

| Density | 1.36 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 2.39 |

| Vapor pressure | 0.4 mmHg (20°C) |

| Acidity (pKa) | 8.5 |

| Basicity (pKb) | 8.5 |

| Magnetic susceptibility (χ) | -67.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.542 |

| Viscosity | 2.34 mPa·s (25 °C) |

| Dipole moment | 1.73 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 129.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -37.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3840.7 kJ/mol |

| Pharmacology | |

| ATC code | D08AE01 |

| Hazards | |

| Main hazards | Toxic if swallowed, in contact with skin or if inhaled; causes severe skin burns and eye damage; may cause respiratory irritation. |

| GHS labelling | GHS02, GHS05, GHS06, GHS08 |

| Pictograms | GHS05,GHS06 |

| Signal word | DANGER |

| Hazard statements | H301 + H311 + H331: Toxic if swallowed, in contact with skin or if inhaled. H314: Causes severe skin burns and eye damage. H410: Very toxic to aquatic life with long lasting effects. |

| Precautionary statements | P260, P262, P273, P280, P303+P361+P353, P304+P340, P305+P351+P338, P310, P405, P501 |

| NFPA 704 (fire diamond) | '3-2-0' |

| Flash point | 76°C |

| Autoignition temperature | 335°C |

| Explosive limits | 3.6–10.6% |

| Lethal dose or concentration | LD₅₀ oral rat 820 mg/kg |

| LD50 (median dose) | LD50 (median dose): 177 mg/kg (Oral, Rat) |

| NIOSH | B015 |

| PEL (Permissible) | 5 ppm (skin) |

| REL (Recommended) | 0.5 ppm |

| IDLH (Immediate danger) | 50 ppm |