The story of 4-vinylcatechol starts back before industrialized organic chemistry found its feet. Early work with phenols and their derivatives opened a door for experimenting with modifications that added vinyl groups to aromatic rings. Researchers found out, through classic reflux setups and plenty of patience, that introducing a vinyl group onto catechol changes more than just its chemical address—it sets off an array of new reactions. By the middle of the last century, interest grew in the material for its potential in polymer and pharmaceutical research. This shift happens every time a niche chemical shows new promise, and 4-vinylcatechol got special attention for the rich set of possibilities created by its two hydroxyl groups and a double bond sitting close together. Over the decades, new preparation methods, often safer and more efficient, brought it to the lab bench and production floor in greater volumes.

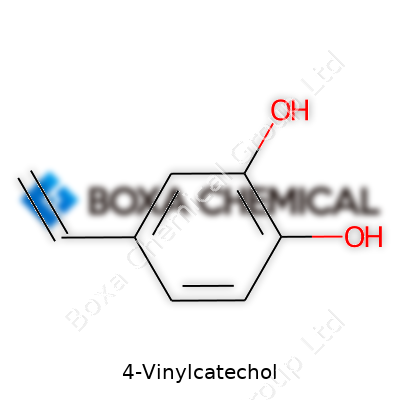

Chemists see 4-vinylcatechol as a useful tool in both research and industrial settings. At its core, this molecule has a benzene ring, two hydroxyls (on the 1 and 2 positions), and a vinyl group tucked onto the 4-position. That setup makes it more than just a building block. It's a reactive intermediate, a monomer for specialty polymers, and a fine-tuned piece for making antioxidants or pharmaceuticals. Industries such as coatings, advanced resins, and fine chemicals look at 4-vinylcatechol as both a target and a turnstile—a way to make and modify things you use every day, whether you're handling formulas or working on the production line.

4-Vinylcatechol comes in as a crystalline solid or can be found as a pale yellowish powder. It melts at low-to-moderate temperatures, depending on purity. Its scent brings to mind faint phenolic notes, which makes sense given its structure. Solubility stays moderate in water thanks to the two hydroxyls, but you see greater solubility in organic solvents like ethanol, acetone, or ethyl acetate. Chemically, it stands ready to join in with addition and condensation reactions, and the double bond in the vinyl group adds plenty of room for polymerization or specific functionalization. As someone who's spent time in synthesis labs, working with compounds like this requires knowing how easily they can oxidize, and 4-vinylcatechol reminds users to work quickly and store carefully.

Suppliers label 4-vinylcatechol under strict guidelines, because handling phenols and vinyls comes with real safety stakes. Purity matters a lot, and you’ll see grades from technical to 99% pure or higher, depending on application and supplier. Material safety data sheets stress the need for chemical-resistant gloves, eye protection, and good ventilation, which match my own hands-on experience. Labels track batch number, date of manufacture, shelf life, and chemical identifiers, with clear hazard pictograms reflecting its irritant and potentially more serious health risks if handled carelessly. Some manufacturers also assign specialized internal catalog numbers for tracking and compliance.

The classic route to 4-vinylcatechol starts with catechol itself. Most pathways introduce the vinyl group through ortho-lithiation followed by reaction with vinyl halides, or rely on palladium-catalyzed cross-coupling that brings in the vinyl moiety at the right place. Skipping steps or rushing through the work-up leads to oxidation or messy byproducts, so time and temperature control take priority. Advances in green chemistry push for milder, safer reagents and less hazardous procedures, reflecting the ongoing dance between performance and process safety. Experienced chemists know that getting a clean product takes patience with recrystallization and attention to the atmosphere around the reaction.

Few molecules handle functional group transformations as flexibly as 4-vinylcatechol. You can polymerize it using free-radical initiators to create dense, heat-stable films. The aromatic ring and vinyl group both respond to electrophilic attack, letting researchers attach new side groups with precision. Its dihydroxy pattern offers anchor points for esterification, etherification, or metal complexation—handy for tailoring physical properties and reactivity. Those modifications feed into making tailored resins or catalytically active materials, where shelf stability and controlled cross-linking pay off for industry and research. Handling the molecule means keeping it dry and out of strong light, as oxidation turns it into colored quinones fast.

Look for names like 1,2-dihydroxy-4-ethenylbenzene or 4-ethenylpyrocatechol in catalogs. Some specialty suppliers brand it with code numbers for their own tracking—if you’re sourcing for scale-up, keeping track of synonyms prevents mix-ups in orders or shelf storage, which makes a difference in busy labs and plants where time and resources run tight.

Handling comes with the same common-sense warnings seen with other low-molecular-weight phenols—don’t touch bare skin, keep it away from open flames, and vent your workspace well. Its irritant properties aren't just laboratory legend; it gets to skin and eyes, so splash goggles and gloves pair up with fast clean-up for any spills. Emergency guidelines call for eye-wash stations and protocols for accidental exposure. Regulatory standards, like those from OSHA or REACH, require careful record-keeping for handling and disposal, and batch traceability supports both safety audits and quality management. In my own practice, storing it away from oxidizers and acids made a real difference in shelf life.

4-Vinylcatechol weaves through specialty coatings, advanced adhesives, antioxidants, and pharmaceutical intermediates. Its double bond entices polymer chemists looking for cross-linkable functionality, while both hydroxyls anchor metal ions, turning it into a useful ligand in coordination chemistry. Antioxidant manufacturers appreciate its radical-scavenging capacity, helping in the preservation of rubbers and food-grade plastics. Medicinal research explores it for modifying lead compounds, improving bioactivity or solubility. Its unique reactivity shapes specialty resins used in electronics and high-performance composites, where reliability and fine-tuned response to stress matter every day on the production floor or in the lab.

Research circles stay interested in 4-vinylcatechol because of what it allows and the barriers that remain. Scientists explore new polymerization conditions, stepping up to block copolymers or hyperbranched frameworks that bring targeted properties—biodegradability or conductivity, depending on the additives or co-monomers. Drug development sniffs out modified catechols for links to enzyme inhibition and antioxidant potential. R&D teams invest in greener synthesis, cutting out toxic metals from catalysts and replacing volatile solvents with water or supercritical fluids. Having worked on some green chemistry projects, it’s clear that each of these steps rides a balance between practicality and regulatory approval.

Studies point out that 4-vinylcatechol can act as a moderate irritant for both skin and respiratory systems, with its structure suggesting possible cytotoxicity if exposure runs too long or at high enough levels. Animal studies delve into LD50 numbers, and cell models test its effect on enzyme function, oxidative stress, and genetic material. Toxicity data inform safe limits for workplace exposure—established through tried-and-true methods paired with modern analytical chemistry. Environmental persistence shows up in research, too, as catechols can influence aquatic toxicity if released accidentally. Health and safety teams draw lines in the sand for exposure, while disposal practices tie back into broader hazardous waste management.

Looking ahead, 4-vinylcatechol sits on the line between new materials and safer processes. Its readiness for further chemical tuning appeals to researchers aiming for next-generation antioxidants, resin modifiers, or pharmacologically relevant frameworks. Industry looks for bulk production at lower cost using bio-based feedstocks, while regulatory drivers push for transparent risk evaluation and lifecycle analysis. Researchers hunt for stable, green reaction conditions and structures with improved performance in specialty coatings or biomedical devices. Collaborations between academia and industry spark new uses that only show up after careful testing and patient iteration. Having seen what a thoughtfully developed chemical can do from both sides of the supply chain, future steps with 4-vinylcatechol will keep balancing clever chemistry against the need to keep workers and the environment safe.

Chemistry has shaped how things get built, protected, and improved across just about every industry you can imagine. Take 4-Vinylcatechol. The name may not roll off the tongue, but this compound pops up in research and manufacturing with surprising frequency.

Anyone who has spent time in a lab knows the frustration of searching for a compound that checks all the right boxes: reacts smoothly, adds features to a molecule, survives a tough process. 4-Vinylcatechol earned a spot on that shopping list. Scientists reach for it when they're after a chemical building block that brings both a handy vinyl group and reactive catechol structure to the table.

What does this look like outside an academic article? I’ve seen 4-Vinylcatechol take on a leading role in making polymers tougher and smarter. The catechol part clings to surfaces, almost like natural glue—you see it in mussels and other shellfish. This property translates well when people want coatings to stick to metals, glass, or plastics.

Industrial researchers learned a lot from nature’s approach. The vinyl group lets chemists attach 4-Vinylcatechol to other chemicals or into long polymer chains through a process called polymerization. That’s the backbone of new adhesives and coatings engineered for use in aerospace, medical equipment, or even construction—anywhere you want a material to cling without breaking down over time.

Drug developers also take interest. 4-Vinylcatechol acts as a stepping stone for pharmaceuticals that fight disease or reduce inflammation. In those labs, they tweak its structure and use those vinyl and catechol features to add new “branches” to molecules or link them together in precise ways.

People sometimes forget how much hinges on tiny improvements in materials. Upgraded adhesives mean electronics hold together longer. Better coatings help ships survive saltwater and harsh weather, shrinking repair costs. New approaches to pharmaceuticals, even using building blocks like 4-Vinylcatechol, push treatments for cancer and chronic inflammation further than older medicines could reach.

Some of the best progress in sustainable chemistry also starts with simple molecules like 4-Vinylcatechol. Because the catechol group comes from a familiar plant-based compound, there’s a path—though it still faces challenges—for manufacturing that could rely less on fossil fuels and more on renewable sources. The push for biodegradable plastics and greener production doesn’t hinge on just one molecule, but tools like this one put those goals within sight.

The story isn’t all smooth sailing. Handling this compound in factories or labs involves risk—you don’t want it drifting into the water supply, and the reactivity that makes it useful can turn into a headache if not managed with careful procedures. That’s where strong regulation and experienced chemical engineers pay off. Good ventilation, responsible waste treatment, and clear protocols for workers mean safety and less environmental impact go hand in hand.

Successful companies invest in staff training, constantly upgrade safety gear, and double-check that every step, from sourcing raw material to finished material, meets the latest standards. For the public, holding manufacturers accountable matters. Communities can ask questions, demand transparency, and push for updates whenever a facility brings in new chemicals like 4-Vinylcatechol.

From high-performance glues in manufacturing to modern approaches in medicine, 4-Vinylcatechol proves that even a single molecule can influence progress in real, tangible ways. With the right mindset and practices, the benefits outweigh the headaches and keep new solutions coming.

Everyday products often trace their roots back to basic molecules. One striking example is 4-Vinylcatechol, a molecule you won’t likely see advertised on a supermarket shelf, but you’ll probably run into its cousins in adhesives, coatings, or even flavors. Its molecular formula—C8H8O2—might look simple. Breaking it down: eight carbon atoms, eight hydrogen atoms, and two oxygen atoms. If you've ever worked with chemicals or taken a chemistry class, you know these numbers can change the story, shifting how a compound behaves, reacts, or helps develop something new.

Experience in laboratory settings has shown me that a small structural change, like placing a vinyl group on a catechol ring, transforms how that molecule works. Catechol itself is a building block in polymers, dyes, and even pharmaceuticals. By attaching a vinyl group at the number-four position, chemists created a compound with more flexibility. It can act as a monomer in making synthetic materials. Its two hydroxyl (–OH) groups on the benzene ring handle hydrogen bonding, changing solubility, and reactivity—all traits that made it valuable for practical uses.

The story of 4-Vinylcatechol is a reminder that chemistry doesn’t stay in the lab. Companies developing specialty resins or new coating technologies often turn to unique molecules for an edge. C8H8O2 gives them a starting material that supports chemical modification. It plays a role in push-pull innovation—balancing performance, environmental safety, and cost. During work on safer adhesives, my team saw that substituting in dihydroxybenzene-based monomers improved performance and cut toxic byproducts. Synthetic variations built on this simple catechol structure supported a safer path for industrial growth. That’s the bridge between molecular structure and better products.

Students, manufacturers, and researchers ask the same foundational question: how do we get from a raw molecule to something truly useful? You need trust in those starting materials. C8H8O2 doesn’t just define what’s in the flask. It sets safety standards, influences reactivity, and helps ensure reproducibility. In my experience, stronger background knowledge led our team to work faster and avoid costly mistakes. We checked every new compound against known molecular formulas, cross-referencing sources like the National Center for Biotechnology Information for accuracy. Mistakes in a formula snowball through batch lab work, regulatory documentation, and even safety protocols. Accuracy in chemistry translates to reputation, quality, and worker safety.

A molecule as simple as 4-Vinylcatechol sometimes gets ignored, lost among more exotic compounds. Truth is, foundational data like its formula, properties, and uses mean more than trivia—they give teachers and students tools for practical learning. Fact-checking and clear communication underpin all reliable chemistry work. A proven approach, in my experience, involves direct links to reputable science databases and asking precise questions whenever doubts arise. Open databases and clear label policies help the larger chemistry community. These steps reflect a foundation of expertise and care, shaping the work of everyone from high school teachers to industrial researchers.

Knowing the formula to 4-Vinylcatechol—C8H8O2—sounds straightforward, but it’s not just about memorizing numbers. It’s about connecting scientific accuracy with real value, giving people the tools to make better products and safer processes. Clear answers and responsible information-sharing shape a more transparent and innovative community—starting with something as small as eight carbon atoms, eight hydrogens, and two oxygens.

Spending years in a chemistry lab, I’ve come across a fair share of finicky chemicals. Some folks underestimate the day-to-day risks that 4-Vinylcatechol brings. It seems low-key, but this compound can become dangerous if stashed carelessly. The key lies in paying respect to its reactivity and tendency to oxidize, which can lead to safety headaches and ruin research-grade material.

From experience, 4-Vinylcatechol reacts with oxygen much faster than people expect. Left on a bench, the solid can turn brown, clump, and sometimes even heat up. Given these traits, storage in an airtight container makes sense. Polyethylene bottles with heavy-duty seals work best—glass jars pick up moisture and sometimes allow air to slip through unnoticed. After one too many ruined batches, I now fill containers almost to the brim, squeezing out as much air as possible. Some colleagues seal theirs under nitrogen for long-term storage, and I’ve seen that keep the chemical bright and active for months.

Leaving 4-Vinylcatechol at room temperature speeds up trouble, especially in humid climates. Warmth nudges oxidation along, and humidity increases the risk of clumping and degradation. I keep the bottles in a dedicated chemical refrigerator, away from the door, so temperature swings don’t zap the contents with every opening. Between 2°C and 8°C gives the right balance—freezer temperatures are overkill and encourage condensation when someone retrieves the bottle.

Even in a refrigerator, direct light shouldn’t hit the sample. I’ve wrapped opaque tape around clear containers in emergencies, but the safest approach uses brown or black bottles. Light, especially UV, speeds up side reactions, and any contaminant from a previous experiment can start chain reactions. Clean tools every time and never dip a used spatula into the sample. I’ve personally lost good material after a distracted grad student used the same scoop on two different chemicals.

More than one accident starts with a lazy label. A container holding 4-Vinylcatechol needs a clear date, hazard symbols, and the name spelled out. No abbreviations or scrawls. Respirators and gloves become essential in handling, since skin absorption and inhalation both cause trouble. Spills on benchtops or inside refrigerators get cleaned up with cold, dilute solutions—never with warm water—because the heat and dilution can kick up hazardous fumes or splashes.

Old or questionable stock shouldn’t linger on the shelf. I’ve gotten into the habit of scheduling quarterly audits—anything brown at the edges or with off smells goes to hazardous waste. Pushing materials past their prime doesn't save money or time; it invites more problems. Sharing protocols and safety tips within a team helps keep everyone sharp and reduces the odds of slip-ups. The stakes add up: improper storage doesn’t just spoil chemicals, it threatens health and research progress.

Whether you’re managing a small teaching lab or a big industrial inventory, these small details keep everyone safer. Proper storage for 4-Vinylcatechol doesn’t demand fancy equipment, just consistent practice, teamwork, and honest respect for the material. Once people see the difference these habits make, they rarely go back to shortcuts.

Most people outside of chemistry circles haven’t heard about 4-Vinylcatechol, but those who work in chemical plants or are involved in research probably have come across it. In day-to-day life, the risks that come with handling or exposure to synthetic chemicals often get lost in technical jargon, but a closer look can inform better choices about health and safety.

Everyone at some point picks up food containers or cleaning supplies filled with ingredients neither pronounceable nor easily understood. It can feel overwhelming. In the case of 4-Vinylcatechol, its story is similar to a range of industrial compounds. It’s typically created as an intermediate during the synthesis of certain polymers and specialty chemicals, and only a handful of professionals actually come into direct contact with it.

Scientific studies have shown that 4-Vinylcatechol can be irritating to skin and eyes. Breathing in the vapors or fine mists could lead to coughing or discomfort in the respiratory system. Toxicity studies from animal models hint at deeper risks: repeated or long-term exposure may impact organs like the liver or kidneys. There’s no room for sugar-coating — nobody wants to develop health complications after a careless spill in the lab or a chemical accident at work.

Governments across the board, including agencies like OSHA and the European Chemicals Agency, keep a close eye on substances like this. They demand clear labels and require companies to provide protective equipment and implement proper ventilation if 4-Vinylcatechol gets used onsite. This isn’t just bureaucracy. Clear rules often draw a line between a routine workday and a hospital visit.

My time working in a polymer chemistry lab opened my eyes to the reality of hazardous substances. During those years, I saw how even small chemical spills led to uncomfortable symptoms. Nitrile gloves, lab coats, and fume hoods weren’t just formalities; they let us walk out of work each day healthy. You come to appreciate the safety data sheets and the alarms that seem to go off for the tiniest issue. A few colleagues ignored warnings, thinking gloves get in the way. They often ended up with rashes, mild burns or, in one case, an allergic reaction that took days to settle down.

No piece of equipment can totally remove risk, but layers of protection do save skin, lungs, and long-term health. I always felt grateful for the regular training sessions — not because the rules seemed fair, but because I saw what happened when shortcuts got taken.

Risk from 4-Vinylcatechol isn’t theoretical. The substance brings dangers that need respect, not just compliance. Strong ventilation, proper storage, and clear labeling keep accidents rare and manageable. Outside big laboratories or manufacturing plants, most people don’t face direct risk. Making sure only trained professionals work with 4-Vinylcatechol, and that they speak up whenever something feels off, builds better safety culture.

Companies do best by limiting unnecessary use of hazardous chemicals wherever possible and seeking less dangerous alternatives. Routine health monitoring and easy access to first-aid supplies also go a long way. Nobody expects to have an accident, but planning for one, and training staff on what to do, can make all the difference between a minor mishap and a tragedy.

People deserve honest, up-to-date information about chemical risks. Knowledge should not get buried inside dense technical papers or hidden behind corporate processes. Making safety a practice, not just a policy, protects workers, families, and entire communities.

Few things shape lab work and manufacturing quite like reliable supply chains. For those working with specialty chemicals like 4-Vinylcatechol, finding a trustworthy source feels a lot like finding a critical tool for your toolbox. This particular compound shows up in advanced synthetic chemistry, pharmaceuticals, and even some materials science research. If the batch quality slips, so do results. If you’ve worked on R&D or scale-up projects, you’ve probably seen delays and extra costs pile up when starting materials don’t measure up. On top of that, purity issues can throw off whole experiments or production runs.

Deciding where to buy usually starts with the basics: purity, consistency, and traceability. From firsthand experience, ordering rare chemicals can feel like rolling dice, especially from suppliers with spotty reputations. Quality matters even more with 4-Vinylcatechol because impurities might react or interfere downstream. That’s not just theoretical. In my own lab work, we once spent weeks tracing a failed reaction back to a contaminated starting material. That lesson sticks.

Large, established suppliers—think Sigma-Aldrich, TCI, or Alfa Aesar—tend to deliver reliable grades and full supporting data sheets. Those data sheets help users double-check the specs before an order goes out. They also usually handle shipments across borders without drama. In regulated or safety-sensitive labs, that kind of assurance matters. If audits or compliance checks are part of your workflow, cutting corners on source can turn small problems into major headaches.

Sticker shock hits hard with rare chemicals. Price jumps aren’t only about grade or amount. Import costs, safety fees, and special packaging all ramp up the number on final invoices. Smaller, niche suppliers sometimes promise big discounts. It’s worth double-checking them on trade registries, industry forums, or even with a quick call to local university procurement contacts. Some groups I’ve worked with keep a running list of who delivered quality versus who sent lots needing extra testing.

Local sourcing seems attractive due to shipping speed. Yet local doesn’t always mean stricter oversight. Some start-ups cut costs by relabeling or reselling from dubious sources. Unless the reseller offers real traceability, I stay cautious. Check for ISO certification, batch retention, and whether customer service can answer technical questions. That builds trust and saves hours chasing down missing paperwork for compliance.

Chemicals like 4-Vinylcatechol don’t travel without paperwork. Import restrictions, hazardous material classifications, and end-use declarations all come into play—especially if you’re moving material cross-border or working with larger volumes. Following up with a supplier’s compliance team at the quoting stage smooths the process. If they can produce safety data sheets, purity certificates, and a simple import process, they stand a notch above in my book.

Reputation, documentation, and direct communication with suppliers shape the real experience of chemical sourcing. Online directories, peer-reviewed vendor lists, and word from trusted colleagues often beat out flashy websites. Reliable suppliers welcome technical questions, provide full documentation, and offer return policies for off-spec material. For those who depend on every reagent living up to its claims, diligence pays off with every shipment.

| Names | |

| Preferred IUPAC name | 4-ethenylbenzene-1,2-diol |

| Other names |

3,4-Dihydroxystyrene 4-Ethenylbenzene-1,2-diol 4-Vinyl-1,2-benzenediol 4-Vinylpyrocatechol 4-Vinyl-1,2-dihydroxybenzene |

| Pronunciation | /ˈfɔːr vaɪˈnɪlˌkætɪkɒl/ |

| Identifiers | |

| CAS Number | 1204-36-6 |

| Beilstein Reference | 1200236 |

| ChEBI | CHEBI:34313 |

| ChEMBL | CHEMBL368271 |

| ChemSpider | 134780 |

| DrugBank | DB04143 |

| ECHA InfoCard | ECHA InfoCard 100.040.258 |

| EC Number | 1.1.1.33 |

| Gmelin Reference | 85948 |

| KEGG | C06198 |

| MeSH | D018099 |

| PubChem CID | 12022836 |

| RTECS number | GF8925000 |

| UNII | 0HWR44PFXA |

| UN number | UN3437 |

| Properties | |

| Chemical formula | C8H8O2 |

| Molar mass | 138.15 g/mol |

| Appearance | Brown to dark brown solid |

| Odor | phenolic |

| Density | 1.159 g/cm3 |

| Solubility in water | soluble |

| log P | 0.95 |

| Vapor pressure | 0.022 mmHg (25 °C) |

| Acidity (pKa) | 9.32 |

| Basicity (pKb) | 12.51 |

| Refractive index (nD) | 1.605 |

| Viscosity | 1.504 mPa·s (25 °C) |

| Dipole moment | 1.41 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 89.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -4.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3137 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | D02AE06 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes severe skin burns and eye damage. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Danger |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-3-2-~ |

| Flash point | 100 °C |

| Autoignition temperature | 460 °C |

| Explosive limits | Explosive limits: 1.1–7% |

| Lethal dose or concentration | LD50 (oral, rat): 220 mg/kg |

| LD50 (median dose) | LD50 (median dose): 610 mg/kg (rat, oral) |

| NIOSH | GV0725000 |

| PEL (Permissible) | No PEL established |

| REL (Recommended) | 25 mg/L |

| Related compounds | |

| Related compounds |

Catechol 4-Ethylcatechol 4-Methylcatechol 4-Vinylphenol Guaiacol |