Chemists working in the 19th century spent plenty of time figuring out how phenolic compounds shaped organic synthesis, human health, and industrial production. 4-Methoxyphenol, better known by names like hydroquinone monomethyl ether or MEHQ, came into focus as researchers tinkered with phenolic cores and simple substituents. Early studies into its structure and reactivity showed chemists the benefits that methoxy groups could bring, especially when attached to the para position. As dye makers and polymer producers grew more ambitious in the early 20th century, this compound popped up in labs and factories as a stable antioxidant and a useful building block. It is odd, looking back, how quickly this modest-looking molecule went from an academic curiosity to a practical workhorse for diverse chemical industries.

4-Methoxyphenol, formula C7H8O2, appears as white crystalline flakes or fine powder, sparingly soluble in water but mixing easily with ethanol, ether, and other organics. Industries rely on it for its role as a polymerization inhibitor in monomer storage and transport – for example, in keeping methyl methacrylate and acrylates from going haywire during shipment or storage. In photographic processing, this molecule acts as a preservative for developing agents. Pulp and paper processors use it as part of antioxidant formulations keeping paper from yellowing. It toes the line between essential industrial additive and specialized laboratory tool, which sums up its reach better than any marketing brochure.

You notice right away that 4-Methoxyphenol displays a melting point near 54-57°C, and it boils at about 243°C. Its molecular mass comes in at 124.14 g/mol, and its density measures around 1.09 g/cm3 at room temperature. The pKa hovers around 10.2, making its phenolic proton acidic enough for targeted deprotonations, yet its methoxy group slows down oxidation compared to plain hydroquinone. This tweak helps it hang around longer under harsh industrial conditions. Its mild aroma gives away its aromatic nature, and under UV light, its benzene ring absorbs well, drawing attention in spectroscopic studies. Unlike some relatives, it doesn’t oxidize in air as quickly, giving it longer shelf life in polymer labs or paint factories.

Producers selling 4-Methoxyphenol have to nail down certain specs. Lab-grade batches often clock purity at or above 99%, and industrial batches demand low moisture—sometimes under 0.5%—to keep performance consistent. Material safety data sheets call out its CAS number (150-76-5), listing flammability and health warnings clearly in compliance with OSHA and EU REACH rules. Bottles ship with hazard pictograms: exclamation marks for irritant properties, flames for combustibility, and clear batch numbers for traceability. Accurate weight, batch composition, country of origin, and expiration dates give users everything they need to handle this compound safely.

One common method to whip up 4-Methoxyphenol—demethylation of anisole’s para position via oxidation, or direct methylation of hydroquinone using dimethyl sulfate or methyl iodide in basic media. Laboratory chemists often choose the latter for predictable yields, and in big reactors, manufacturers tend to prefer methylation because it scales cheaply and recycles reagents efficiently. Purification involves cooling to precipitate the product, filtration, and then distillation under reduced pressure. Quality checks nail down purity by thin-layer chromatography, high-performance liquid chromatography, and melting point analysis. Every step, from glass beaker to drum-scale reactor, feels steeped in a century of practical know-how—there are few surprises left, at least in terms of basic synthesis.

The story of 4-Methoxyphenol doesn’t end with its vanilla appearance on a production line. This molecule stands out for its chemical flexibility. Nucleophilic substitution on its methoxy group opens the door to bigger and more complex molecules. Electrophilic aromatic substitution happens with speed at the ortho and para positions, letting synthetic chemists shape dyes, pharmaceuticals, and antioxidants. 4-Methoxyphenol takes on bromination, sulfonation, and acylation—each reaction generating something a bit different, useful in ink, medicine, or fine chemical labs. Its tendency to stabilize free radicals gives it a starring role in inhibiting unwanted chain reactions, a trait much sought after in polymer science and paints where color and texture can make or break a product’s value.

Anyone leafing through a lab catalog or bulk chemical supplier’s list finds a pile of aliases: MEHQ, Hydroquinone Monomethyl Ether, 4-Hydroxyanisole. Some operations slap proprietary names on their drums—Rölite MEHQ, ParaMeth, or Methoxyphen. The overlaps reflect decades of trade, mergers, academic quirks, and trademark registrations. Reading safety literature demands attention to these synonyms, since they all point to the same core structure and, often, the same set of risks and handling needs.

Operations that keep workers and products safe treat 4-Methoxyphenol with the respect it earns. Goggle-wearing, glove-donning, and good ventilation keep skin and airways safe. Industrial operations that weigh out tankfuls stack local exhaust hoods and process automation on top to prevent vapor buildup and dust clouds. Storage in amber bottles or drums wards off photodegradation. National and international regulations slot 4-Methoxyphenol in lists of hazardous substances, so shipping and handling standards run under rules like OSHA, REACH, and GHS. Safety training walks workers through first aid for accidental spills, fire hazards, and decontamination protocols. Users keep proper records on use, exposure, and disposal, with hazardous waste shipped to licensed handlers. Nothing fancy—just good, diligent safety culture born of hard lessons.

You spot 4-Methoxyphenol wherever chemistry meets commerce. Polymer plants need it to stabilize acrylates, styrenes, and other reactive monomers. Photographic firms prize its antioxidant effects, stopping color developers from spoiling. Cosmetic researchers look at it as a skin-lightening agent, though regulatory cracks have started to show in that application because of safety concerns. Ink and dye makers put it into formulations that resist oxidation, yielding brighter, more durable colors. The molecule’s reach goes even further: in rubber manufacturing, as a stabilizer for latex emulsions, and in select flavor and fragrance formulas, thanks to its smooth aromatic profile.

Inside R&D labs, scientists dig for new ways to tune 4-Methoxyphenol’s behavior. Modified derivatives—halogenated, nitrated, or longer chained—open up new families of antioxidants, UV filters, and pharmaceutical intermediates. Analytical labs keep testing mixtures where trace MEHQ matters for stability, taste, or safety. As green chemistry grows, engineers hunt for less toxic methylating agents and recyclable solvents to cut process waste and exposure. Academic groups map out the electron-donating effects of the methoxy group, testing model reactions for bigger, more ambitious synthesis plans. All this energy points to a molecule with more road ahead than behind—small changes to its structure can yield big gains in performance or safety for tomorrow’s products.

Researchers in toxicology keep a close eye on exposure risks. Direct contact with 4-Methoxyphenol can cause irritation, redness, and even allergic reactions for sensitive skin; inhaling dust can rattle lungs. Chronic exposure in animal studies links to pigment changes and, in rare cases, organ toxicity, especially in the liver and kidneys. Regulatory agencies in Europe and North America set occupational exposure limits, backed by long-term health surveys and patch testing in workers. Labels warn against dumping into waterways, since aquatic organisms struggle with even low concentrations. Clinical reports remind every handler: gloves and masks aren’t just paperwork—they’re a frontline barrier when working with powders or hot solutions.

As manufacturing upgrades and sustainability demands sharpen, the future of 4-Methoxyphenol hangs on safer process chemistry and better end-user protection. Chemists in industry look for ways to recycle or neutralize spent product before shipping waste off-site. Increasing demand for biocompatible, green stabilizers prompts researchers to compare synthetic phenols and their natural cousins. Automation in production could shrink human exposure even further, cutting accidental contact and measured emissions. Researchers testing next-generation antioxidants and anti-aging formulas in biotechnology keep modifying this core molecule, opening new commercial and medical uses. In a field that never sits still, a simple aromatic ether like 4-Methoxyphenol shows how the old standards adapt and grow, provided their risks and strengths stay under close watch.

4-Methoxyphenol, known in labs as MEHQ or Hydroquinone Monomethyl Ether, plays a bigger role in daily life than most folks realize. I got curious about this compound after hearing chemists talk about it at a university open house. Some people treat chemical names like a warning sign, but after learning how this compound fits into real-world products, it started to make sense why we keep hearing more about it.

If you work anywhere near plastic manufacturing, you might know the headache of runaway polymerization. Liquid monomers—think acrylics or styrene—like to clump together given the tiniest spark. Out of control, that process can turn a factory into a hot mess. Companies started mixing in MEHQ as a stabilizer to keep things under control. MEHQ stands guard, stopping premature polymerization and making it possible to store and transport those reactive building blocks safely. Without it, entire batches might spoil during shipment. Factories save serious cash and cut down on hazardous waste because this compound lets them manage those risks.

The story of 4-methoxyphenol doesn’t stop at industrial plastics. Anyone who’s picked up a bottle of hair dye has probably encountered this compound without knowing it. MEHQ acts as an antioxidant in cosmetics and skincare products, protecting sensitive ingredients from breaking down while they sit on store shelves. Hair color developers especially run into trouble with air exposure. MEHQ helps preserve formulas and stop unwanted reactions, so customers don’t get an unpleasant surprise.

I’ve met people with sensitive skin worried about every new chemical in a product. Good regulation makes a difference. The FDA and European Chemicals Agency pay close attention, keeping MEHQ’s concentration within safe limits. This lets companies use it to extend shelf life, all while looking after users’ health.

Anyone working with pharmaceuticals knows air and light don’t play nice with delicate drugs. MEHQ steps in here, as well. You’ll find it used to stabilize active ingredients so medicines reach patients still effective. What stood out to me: research papers keep calling MEHQ a “sacrificial” antioxidant. It willingly reacts first, getting consumed in the process and protecting the important parts.

Not every story about chemicals brings comfort. Misuse or overexposure to MEHQ can lead to skin irritation, especially for people working with it every day in factories. That’s why the government demands clear labeling and sets workplace exposure rules. I heard a safety specialist mention that a good mask, gloves, and some ventilation go a long way for those on the shop floor. Knowing that the risks have managed boundaries makes me feel better about MEHQ’s spot in products we use.

Calls for greener chemistry push for new alternatives to these stabilizers. Some research groups explore plant-based antioxidants, but MEHQ remains tough to replace. For now, the best approach might be smart handling and close monitoring. Responsible manufacturing and honest conversation make a difference. Recognizing this compound’s value, keeping exposure in check, and searching for smarter alternatives strike the right balance for industries and consumers.

4-Methoxyphenol, sometimes called hydroquinone monomethyl ether, pops up on the shelves of many laboratories. Its job list covers everything from stabilizing certain monomers to playing a part in chemical synthesis. But the convenience hides some real risks if you don’t treat it with respect. I learned early on, after a cracked pair of gloves and a rough reaction, that this isn’t the sort of compound you handle with a coffee in hand and a distracted mind.

This chemical can irritate the skin and eyes pretty quickly. Inhaled dust or fumes can bother throats and lungs. Accidents involving organics don’t always make a scene, but overexposure leads to headaches, nausea, dizziness, and sometimes worse if you’re not listening to your body. Skin contact can sneak up — maybe an itch, maybe a red rash or even blisters. Eyes hit with even a little splash feel the sting, and anyone who’s worked through that knows it’s no small annoyance.

I learned to check gloves before pulling a new bottle out of storage. You want nitrile or neoprene instead of the cheap latex types. Aprons and lab coats aren’t just for show. Splashes can happen fast, and the extra layer gives you time to wash chemicals off before they do real damage.

The eyes need their own defense. Safety goggles are non-negotiable. I once skipped them in a rush and paid with burning eyes for an hour. It only takes one missed step to regret it. Respiratory protection only comes into play if you’re making dust or fumes. Good ventilation does most of the work — solid ducting or a real fume hood, not just cracking a window.

4-Methoxyphenol belongs in a cool, dry spot away from sunlight and sources of ignition. Tight caps, sturdy containers, and clear labeling keep mishaps to a minimum. Storing it next to acids or oxidizers courts trouble. I’ve seen colleagues learn that lesson the hard way. Take five minutes to set things up right and you’re less likely to spend hours dealing with a spill.

Spills demand attention, not panic. I grab absorbent materials, gloves, and a mask before tackling cleanup. Small spills get mopped up and sealed in a proper waste container. Larger incidents mean it’s time for the safety officer and a bigger cleanup crew. Eye wash stations and showers should be within reach. In labs I’ve worked in, drills keep everybody sharp about how to find these emergency rinses even with eyes shut tight.

I’ve learned not to cut corners, not just for yourself but for the people working nearby. Label everything clearly, share your knowledge, and don’t assume everyone knows the same protocols. Group safety only works when experienced hands remind new colleagues where things go wrong and how to fix them. Good training sticks. I still remember the instructor who punctured a glove on purpose in front of the class to show how quickly skin contact can happen. It stuck with all of us.

Science moves ahead by learning from mistakes. Adopting regular training, keeping current with safety data sheets, and sharing hard-earned lessons help everyone work smarter. Digital inventory tracking has helped avoid surprise shortages or dangerous overstock. Open communication within teams and a willingness to review near-misses encourage a culture where speaking up is valued. Trusting these systems means safer labs, and that benefits not just the researcher but the whole community.

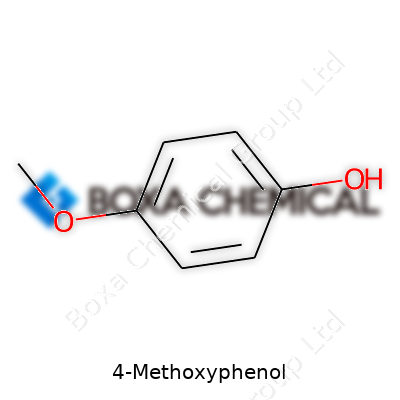

Walk into any pharmacy or chemistry lab, you'll spot dozens of containers with names that don’t roll off the tongue. One of these, 4-Methoxyphenol, carries usefulness that goes beyond what most people imagine. Its chemical formula reads as C7H8O2. If you picture its structure, a benzene ring sits at the core, one side hosting a methoxy group (-OCH3) at the para position, the opposite holding a hydroxyl group (-OH). In chemistry, para position means the two groups stand opposite each other on the benzene ring, which, in this molecule, means positions 1 and 4.

Many years in the lab have taught me that molecules with small tweaks in structure can behave wildly differently. 4-Methoxyphenol helps keep photographic developers stable and stops them from going bad, so it found a solid place in photography before the digital age changed things. It also works as an antioxidant in cosmetics and personal care products, protecting formulas from spoiling due to exposure to oxygen. You’ll spot it in some skin whitening creams acting as a skin lightener, where its molecular shape lets it interfere with the processes that create pigment.

The remarkable part is that these features don’t show up by luck. The methoxy group helps make it more fat-soluble, so it moves easily across cell membranes, and the phenol part allows participation in reducing reactions. Together, these groups push the molecule to become a scavenger for free radicals. This isn’t just lab talk: free radicals speed up the aging of skin by damaging cells, so halting them means smoother creams that bring real benefits.

Chemical safety counts for a lot. I’ve seen plenty of new researchers get caught off guard by chemicals that seem harmless on paper. 4-Methoxyphenol isn’t especially toxic in small doses—it’s used in tiny amounts for cosmetics or pharmaceuticals. But it can cause skin irritation and allergic reactions, so gloves and good ventilation matter in the lab. Some countries watch over its use in skin-lightening products because of concerns about misuse and potential long-term effects.

Environmental responsibility needs attention too. As manufacturing expands, more by-products find their way into water streams. This compound breaks down in the environment, but carelessness in disposal can add unnecessary chemical load to our water systems. Proper containment, prudent disposal, and following regulatory frameworks protect both lab workers and the wider ecosystem.

No single molecule answers every need. Companies aiming for better skin care or industrial additives should keep searching for alternative antioxidants that carry lower risks—both for people and for the environment. Some have moved towards plant-based polyphenols or vitamin E derivatives, which handle many of the same jobs without causing as many worries about toxicity.

Detailed understanding of molecules like 4-Methoxyphenol helps shape safer consumer products, better lab practices, and smarter regulations. Every bottle in a lab or on a shelf reflects thousands of hours of research, not just in finding something that works but also something that won’t do harm over time. That’s worth every bit of deliberate consideration and care we can give.

Many folks working with chemicals might know 4-Methoxyphenol under different names, like Mequinol or p-hydroxyanisole. This compound pops up in labs, factories, and even in some cosmetic formulations. By experience, letting your guard down on proper storage can turn a tool into a headache fast. Chemicals react to light, air, temperature, and moisture. Each variable has a knack for triggering problems if ignored.

4-Methoxyphenol easily oxidizes in the presence of air and light, which starts a chain of chemical changes that may lead to degradation or risks like container rupture. Years back, I heard stories about bottles left near heaters. Instead of a fine white powder, the contents turned brown and formed lumps, proving with no uncertainty that conditions matter. Most chemical suppliers print warnings on labels for a reason—no one wants fires, ruined stock, corroded labels, or, worse, a trip to the emergency room.

Long-term value and safety grow directly from storing this compound in a cool, dry spot. Room temperature never means in the direct path of sunlight, nor next to any heat source, including radiators or the sunny side of a window sill. If you’re using one of those classic brown (amber) glass bottles, stick with that. Amber glass absorbs light, and this simple choice slows down degradation.

Air tightness makes a huge difference. Oxygen starts up a slow decay process, turning useful chemicals into nothing more than hazardous waste. I recommend resealing inserts promptly and ensuring a solid cap. Silica gel packs or other desiccants come in handy for keeping moisture away because clumped powders aren’t just messy—they can increase the risk of uneven reactions if the compound finally gets used. Humidity not only messes with quality but may create an environment for mold or corrosion on the cap and thread, which is unwelcome even just from a maintenance standpoint.

Segregation from incompatible substances is another real concern. Strong acids, bases, or other oxidizers stored close together create chances for unexpected reactions. Reading material safety data sheets for linked risks ranks higher than relying on institutional memory, as even seasoned professionals can forget details.

I’ve learned that no “special” cabinet exists for every item. General chemical storage rules apply, but those with a lot of experience prefer airtight amber containers on shelves well below eye level, away from foot traffic and heat. Labels should show purchase and expiry dates. Regular inventory checks prevent accidental use of degraded or expired samples, which helps everyone down the line. Staff training, clear labeling, and updated handling SOPs stop “casual mistakes.” No one in my teams has regretted labeling bottles with big, bold “Protect from Light & Air” warnings.

No plan holds up unless it covers the day something goes wrong. Even a tiny spill calls for gloves and, where possible, a fume hood to limit exposure. Waste containers should lock tightly, and nothing should ever get left to evaporate into workspaces. Many labs choose designated waste streams to handle expired 4-Methoxyphenol, keeping it far from household or general lab trash.

Overall, keeping 4-Methoxyphenol at its best comes down to respect for the chemical and for your team. Simple, thoughtful practice trumps careless shortcuts every time.

4-Methoxyphenol pops up in more places than people might expect. I once volunteered in a chemistry lab where bottles labeled with unfamiliar names sat on every shelf; this chemical, also called hydroquinone monomethyl ether (MEHQ), was a stabilizer in polymer production and served as an antioxidant in a range of products. It’s trusted for its ability to keep reactions under control, and manufacturers rely on it—yet its potential downsides don’t get close to the headlines they should.

A person who works with MEHQ soon learns there’s a sting in the air and a slight burn if you spill a drop. The main health risk comes from skin contact and inhaling vapors. The U.S. National Library of Medicine points to its role as a skin and respiratory irritant. This has matched what I’ve seen—red hands, mild coughing, irritation in sensitive folks. Repeated or high exposure could set off dermatitis, and in rare cases, more serious reactions. Eye protection and gloves aren’t just a good idea—they keep hospital visits off your calendar.

MEHQ gets used in some skin-lightening creams. It blocks melanin. Topical misuse, especially in high concentrations, can damage skin, trigger allergies, and compromise natural UV protection. The World Health Organization has flagged this type of chemical use as risky in cosmetics, leading to restrictions in various countries.

No clear evidence links typical workplace levels to cancer or systemic diseases. The U.S. Occupational Safety and Health Administration (OSHA) has not classified MEHQ as a carcinogen, but little long-term safety data exist. Chronic low-level exposure remains a blind spot. I’ve known lab colleagues who never noticed a problem until a random allergy test years later turned up a sensitivity, which speaks to the silent risks.

Once MEHQ makes its way into wastewater, there’s a risk for aquatic ecosystems. A 2018 study published in Ecotoxicology and Environmental Safety found that MEHQ harms aquatic life, affecting fish and algae even at low concentrations. It doesn’t break down rapidly in water, leaving the door open for accumulation. Disposing of it as regular lab waste isn’t safe. I remember the scramble once, during a spill, to keep drains covered and contact environmental health specialists. Their response emphasized—this isn’t something to take lightly.

Most municipal water treatments aren’t designed for exotic organics like MEHQ. That means traces could find their way into rivers and drinking water if industry doesn’t handle disposal responsibly. Environmental guidelines from the European Chemicals Agency stress the need for strict containment and disposal procedures.

Industry transparency counts. Manufacturers have a duty to warn, offer clear instructions, and provide personal protective equipment recommendations. Substituting MEHQ with less hazardous stabilizers where possible could go a long way. For labs and factories, spill kits and proper ventilation systems make a big difference. Clear labeling and training proved their worth more than one nervous afternoon during my time on the bench.

At home, steer clear of cosmetics with ingredients you can’t easily look up and verify as safe. Regulators gain ground by updating safety reviews and enforcing limits on the quantities used. We need more research, too—if chronic exposures are still a question mark, targeted studies could save headaches and lawsuits down the line. If everyone who handled or regulated MEHQ took these steps, the chemical’s risks to people and the environment could shrink, instead of lurking unseen for years.

| Names | |

| Preferred IUPAC name | 4-Methoxyphenol |

| Pronunciation | /ˌfɔːˌmɛθ.ɒk.siˈfiː.nɒl/ |

| Identifiers | |

| CAS Number | 150-76-5 |

| Beilstein Reference | 1209247 |

| ChEBI | CHEBI:17721 |

| ChEMBL | CHEMBL1401 |

| ChemSpider | 682 |

| DrugBank | DB03816 |

| ECHA InfoCard | 100.005.342 |

| EC Number | 205-769-8 |

| Gmelin Reference | 81142 |

| KEGG | C01651 |

| MeSH | D015746 |

| PubChem CID | 722 |

| RTECS number | SL8225000 |

| UNII | K0A3UF671V |

| UN number | 2811 |

| Properties | |

| Chemical formula | C7H8O2 |

| Molar mass | 124.14 g/mol |

| Appearance | White crystalline solid |

| Odor | slight phenolic |

| Density | 1.117 g/cm³ |

| Solubility in water | slightly soluble |

| log P | 1.34 |

| Vapor pressure | 0.01 mmHg (25°C) |

| Acidity (pKa) | 10.2 |

| Basicity (pKb) | 10.20 |

| Magnetic susceptibility (χ) | -62.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.542 |

| Viscosity | 3.266 mPa·s (25 °C) |

| Dipole moment | 1.69 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 99.3 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -134.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3255 kJ/mol |

| Pharmacology | |

| ATC code | D02AE02 |

| Hazards | |

| Main hazards | May cause fire; harmful if swallowed, inhaled, or absorbed through skin; causes skin and eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. May cause an allergic skin reaction. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P270, P271, P272, P273, P280, P301+P310, P303+P361+P353, P304+P340, P305+P351+P338, P306+P360, P308+P311, P312, P321, P330, P337+P313, P362+P364, P370+P378, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 2-2-0 |

| Flash point | 79 °C |

| Autoignition temperature | 280°C |

| Explosive limits | 3.6% - 29% |

| Lethal dose or concentration | LD50 oral rat 1600 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral-rat 1600 mg/kg |

| NIOSH | JN8225000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 4-Methoxyphenol: 5 mg/m³ |

| REL (Recommended) | 0.5-1% |