The chemical industry has a long history of tinkering with the simple benzene ring to create versatile compounds, and 3-chlorophenol stands as a product of this pursuit. Chemists began synthesizing chlorinated phenols in the late 19th and early 20th centuries as the demand for antiseptics, disinfectants, and dye intermediates grew. By the mid-1900s, industries found new value in these compounds, particularly with the rise of plastics, herbicides, and pharmaceuticals. The chlorination of phenolic compounds was never just academic; it answered real needs, driven by agriculture and public health. Over the decades, as regulation and environmental awareness advanced, industries saw the importance of safe handling and rational use, and 3-chlorophenol’s place became more clearly defined by its utility and risks.

3-Chlorophenol, a chlorinated derivative of phenol, brings together the recognizable phenolic odor with a broad utility toolbox. It presents as a colorless to pale yellow crystalline solid, though older batches may appear straw-colored due to aging or minor impurities. Used widely as an intermediate, this compound doesn’t stand alone—its value relies on being part of something larger: disinfectant formulations, dye stocks, and raw material for synthetic flavoring agents. Notorious in environmental circles due to its persistence and odor, this chemical gets more scrutiny than its sibling molecules, yet it maintains a stronghold in processes that require tailored reactivity and specific chemical footprints.

Looking at the core data, 3-chlorophenol offers a melting point near 32°C, which means at room temperature, the compound can solidify easily, complicating transport in cooler climates unless storage containers remain warm. Its boiling point hovers just above 213°C; volatility during lab work or manufacturing deserves attention, given the distinctive and pungent phenolic scent. Solubility tells another story: only moderate miscibility with water but far better solubility in organic solvents such as ether and alcohol. This solvent-friendly nature makes extraction and reaction easier in many applications. The molecule’s phenolic hydrogen activates the ring toward further substitution, yet the chlorine atom on the meta-position adjusts reactivity, making selective synthesis both possible and sometimes tricky.

For suppliers and end-users alike, technical specifications matter beyond purity alone, though standard grades often meet or exceed 98% on dry basis. Companies involved in pharmaceutical synthesis or electronics need even higher purity, with trace metal and halide levels tightly controlled. Labeling requirements fall under global chemical guidelines: the Globally Harmonized System (GHS) demands pictograms for toxicity and environmental hazard, clear instructions about storage and accidental release, and batch-specific identifiers for traceability. Handling protocols are not window dressing—they form a core part of regulatory compliance, and any deviation risks both worker safety and local environmental standards.

Production relies mostly on direct chlorination of phenol in controlled reactions, with catalysts and temperature dictating the ratio of ortho, meta, and para substitution products. Obtaining the meta isomer, 3-chlorophenol, calls for either careful manipulation of process parameters or a two-step synthesis where phenol undergoes sulfonation followed by chlorination and subsequent desulfonation. Such techniques reflect the balancing act between selectivity and yield; every plant operator recognizes the importance of process control. Some producers adopt catalytic hydrogenation or oxidative dechlorination to recycle unwanted byproducts, reducing waste and cutting costs.

Once on hand, 3-chlorophenol serves as a springboard for a range of chemical modifications. It reacts readily in electrophilic aromatic substitution, opening doors to further halogenation, nitration, or even Friedel-Crafts alkylation for specialty intermediate synthesis. In the pharmaceutical industry, skilled chemists exploit its reactivity to create ethers, esters, and other derivatives serving as part of drug candidates or active ingredients. Oxidation and reduction reactions provide additional tracks, supporting research into bioactive molecules or agrochemical leads. Even at the bench scale, the molecule stands out for its predictable behavior and manageable side products.

In the world of chemicals, naming conventions sometimes trip up even seasoned scientists. 3-Chlorophenol may show up as m-chlorophenol, meta-chlorophenol, or 3-hydroxychlorobenzene on datasheets and shipping manifests. The diversity of names points less to confusion than to broad adoption across fields—one industry prefers the systematic name, another leans on traditions set decades ago. For regulatory tracking and global trade, companies refer to standardized identifiers such as CAS Registry Numbers, easing the work of customs agents and safety auditors.

Chlorinated phenols raise flags for health and environmental impact, and 3-chlorophenol is no exception. Occupational safety revolves around strict controls: sealed handling systems, eye protection, gloves, and, for large-scale operations, closed-loop ventilation. Users pay close attention to proper waste management as accidental releases or poor disposal threaten local rivers and soil. The material’s toxicity to aquatic organisms puts pressure on disposal practices—wastewater treatment plants require specialized filters and advanced oxidation steps. For community health, regulatory bodies set workplace exposure limits and track spills under hazardous substance protocols.

From antiseptics and disinfectants to intermediates for dyes and pesticides, 3-chlorophenol has a reach that cuts across several sectors. While manufacturing of herbicides and fungicides soaks up significant tonnage, specialty applications persist: aromatic polymers, specific pharmaceuticals, and even flavoring agents (in trace, tightly controlled amounts). As urbanization and changing lifestyles shift disease and pest threats, global demand sees periodic rebounds, with agricultural surges fueling spikes. In research settings, 3-chlorophenol enables the synthesis of complex organic structures, supporting both academic curiosity and industry-driven exploration.

A substantial share of current research centers on process innovation and risk mitigation. Teams explore green chemistry alternatives to reduce hazardous byproducts, aiming for catalytic systems that operate at lower energy inputs and generate fewer wastes. Academic inquiry probes deep into reaction mechanisms, seeking clues to unlock better selectivity and yield. In toxicology, researchers look for breakdown pathways—how the molecule degrades in wastewater, what metabolites form in living bodies, or which bioremediation methods offer hope for real cleanup. Patents reflect renewed interest in functional group conversions, leveraging 3-chlorophenol for next-generation pharmaceuticals and crop protection agents.

Toxicologists have long focused on the risks posed by chlorinated phenols. Exposure through skin or inhalation carries acute dangers: irritation, systemic toxicity, and in high doses, damage to the kidneys or liver. Environmental scientists, too, labor over the persistence of 3-chlorophenol in soil and surface waters—plants, fish, and invertebrates all show sensitivity at surprisingly low thresholds. These risks force sustained investment in personal protective equipment and process controls. Long-term toxicity studies link chronic exposure to organ failure and, in some cases, developmental toxicity in animals. This research carries weight in regulatory decisions, shaping both workplace standards and effluent guidelines.

Global industrial trends point to a future where safety and efficiency drive demand for better ways to work with 3-chlorophenol. Regulations around discharge and residuals will tighten, pushing users to embrace closed-loop manufacturing and greener organic synthesis pathways. Advances in catalysis hold promise, with recyclable metal complexes targeting selective chlorination and downstream conversions. Digital tracking and real-time monitoring grow more common as producers seek to reassure local authorities and international partners that their processes meet the highest standards. The race for new antimicrobial and plant protection compounds keeps labs busy around the world, with 3-chlorophenol serving as one stepping stone among many. Companies that invest in cleaner, safer technology will shape the profile of this chemical for the next generation.

3-Chlorophenol doesn’t often come up in daily conversation, but its fingerprint shows up in places many folks wouldn’t expect. Pull apart the lives of industrial cleaners, healthcare workers, lab chemists, and even workers on farmsteads, and you’ll spot traces of this chemical in the toolkit. I once spent a summer job in a plant nursery that took mold prevention seriously—3-Chlorophenol had a place on our storage shelf, locked and labeled, so it wouldn't land in the wrong hands. It carried a strong smell and a stronger warning. Its uses stretch wider than many would guess, but that also brings a load of responsibility.

Hospitals rely on compounds with punch. Disinfectant products built with 3-Chlorophenol target bacteria and fungi on hard surfaces—counters, surgical tools, bathroom tiles. That antimicrobial action isn’t just about surface gleam; it’s about stopping infections in their tracks. Schools, food factories, and even tattoo parlors use cleaners that tap into this same power. The bite comes from chlorination. Microbes don’t stand much chance, but the residue and fumes have to get handled with care.

The story doesn’t stop at cleaning. Step inside a chemical plant, and you’ll find 3-Chlorophenol used to make dyes, medicines, and other chemicals. Paint labs sometimes turn to it while mixing stabilizers, and pesticide manufacturers mix it into the formulas for insecticides and herbicides. Take agricultural fungicides as an example: farms and vineyards need weapons against mold and rot. I once watched an agronomist explain how trace amounts in controlled environments could save acres of crops from spoilage, if managed wisely.

3-Chlorophenol lends itself to making drug building blocks. The pharmaceutical world works with it during the synthesis of antiseptics and local anesthetics. Its presence rarely ends up in the pill cabinet at home, but it shapes the active ingredients on the production line. This is the part that makes regulators squint closely. They want to know that residue doesn’t sneak its way from lab bench to pill bottle.

The trouble with a chemical weapon is how tightly it needs controlling. The same chemical that knocks out mold or bacteria in a hospital raises questions about human and environmental health. Prolonged or careless exposure to 3-Chlorophenol can bring a heap of trouble—skin irritation, breathing problems, and even long-term toxicity if it spills or seeps into groundwater. Regulatory agencies in the US and Europe treat it with the caution it deserves.

Solutions start with smart handling and solid education. Every workplace I’ve stepped into that deals with potent disinfectants makes safety gear and handling protocols a top priority—gloves, masks, and proper ventilation aren’t up for debate. Clean-up teams and manufacturing lines follow strict waste disposal measures to stop environmental releases. The chemical industry also puts in research hours, working on greener alternatives that keep bacteria at bay without side-stepping public health or environmental safety. Open lines between science, law, and the people on the ground remain key. Mistakes with substances like this take years to clean up.

Responsible use matters. It’s not just rules on a sheet or check marks on a clipboard. It takes workers, scientists, and communities that speak up, double-check labels, and stay curious about what’s going into cleaners, medicines, and sprays. With chemicals like 3-Chlorophenol, a little awareness stretches a long way—and that makes a difference far beyond the lab.

Working with 3-Chlorophenol means taking real risks. This compound releases a sharp odor that hints at how dangerous it can get, even in small amounts. Over the years, I’ve seen how quick it can irritate skin or sting the eyes. Records from the National Institute for Occupational Safety and Health show repeated exposure leads to symptoms like dizziness, headaches, and damage to organs. Even a moment of contact can cause chemical burns that take weeks to fade. There’s no reason to roll the dice just for convenience.

Gloves form the first line of defense. Not just any latex or vinyl will cut it—nitrile or neoprene gloves do the job. Don’t forget chemical splash goggles with wraparound protection. Standard safety glasses might let vapors sneak past. Cover as much skin as possible with a proper lab coat or even better, an impervious apron. A face shield protects if there’s even a hint of splash risk. Many argue about comfort versus safety in the lab, but a chemical burn on the cheek settles that debate fast.

One thing I learned early: never trust the open air to clear out toxic fumes. Use a certified chemical fume hood. These aren’t luxury lab equipment; they are mandatory whenever 3-Chlorophenol leaves a sealed container. Modern ventilation systems don’t replace a fume hood—too many lab accidents prove this point. If working outside a proper hood, chances rise for inhalation or environmental spill, even with a window open.

Every bottle of 3-Chlorophenol needs a cool, dry spot, far from sunlight or any heat source. The cap should always close tight, and never reuse old, unlabelled containers. Store it alongside other hazardous organics, away from anything with acids or oxidizers. Too many close calls start with someone storing incompatible chemicals side by side.

Spills happen fast—buffering them with absorbent pads and having neutralizing agents on standby saves a lot of trouble. Handle small volumes at a time to limit the risk. Working with a buddy helps; there’s no substitute for another pair of eyes ready to catch a mistake or help in an emergency. Once, I saw a colleague collapse just from sniffing a whiff that lingered after an unnoticed spill. Alone, the outcome might have been much worse.

Pouring 3-Chlorophenol into the drain or trash isn’t just illegal—it’s reckless. Hazardous waste needs to go in thick-walled, clearly marked containers. Many municipalities run take-back programs or partner with certified chemical waste handlers. Fines for improper disposal run high, not to mention lasting damage to community water supplies. I always double-check local regulations before sending out any waste—mistakes here create health problems for whole neighborhoods.

Even with every precaution, accidents still happen. Emergency showers and eye wash stations should sit within arm’s reach of any work area. Knowing their exact location, and how to use them, saves precious seconds. If someone gets splashed, get them under running water immediately, and call medical help. Time wasted searching for a first aid kit can leave scars that last a lifetime. I once watched a young tech lose weeks of recovery time just because the eyewash station got blocked by storage crates.

Handling chemicals like 3-Chlorophenol never feels routine. Proper training, honest communication about hazards, and peer accountability form the backbone of a strong safety culture. Double-checking each other never gets old; it keeps everyone honest. A single careless act can change lives. So, stay alert, wear the right gear, follow every procedure, and take pride in going home healthy every night.

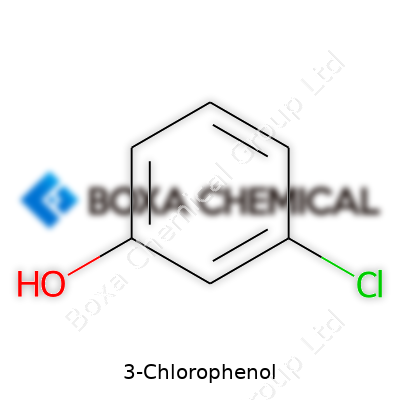

3-Chlorophenol belongs to a group known as chlorinated phenols. Each one looks similar, but the position of the chlorine atom changes how they behave. In 3-Chlorophenol, the chlorine atom attaches to the third carbon of a benzene ring. The formula is simple: C6H5ClO. For most people, this number isn’t just a jumble of letters—it reveals a lot about how the molecule acts and why you’d find it in certain products.

Anyone who’s handled basic organic chemistry models remembers the hexagonal shape that pops up everywhere—the benzene ring. 3-Chlorophenol has six carbons forming this stable core, with a single chlorine atom on the third carbon, and a hydroxyl group (–OH) on the first carbon. The numbers show up as “meta-position” because the chlorine skips one spot after the hydroxyl. This arrangement shapes everything from how it dissolves in water to the way it interacts with other chemicals. Some of us got our first whiff of its sharp smell in high school labs because it acts as both a disinfectant and an intermediate in making pharmaceuticals.

Details in molecular structure can make or break chemical performance. With 3-Chlorophenol, the placement of the chlorine changes its reactivity. That single atom can lead to very different toxicity compared to, say, 2-Chlorophenol or 4-Chlorophenol. Some companies use 3-Chlorophenol when they want a molecule that isn’t too aggressive but still punches through tough stains or bacteria. It finds its way into antiseptics, dyes, and sometimes pesticides. Those working around these compounds often talk about the care needed because even small changes in placement can cause unexpected reactions.

Talking about chemicals like this isn’t just for chemistry fans. 3-Chlorophenol shows up in polluted rivers and often raises alarms in water monitoring reports. In my early days of working with groundwater remediation, the sharp chemical scent in certain wells signaled phenols in the water. This compound doesn’t break down quickly. Studies from the EPA highlight its persistence and potential to harm aquatic organisms even at low levels. Wastewater plants struggle to filter out phenols, leading to ongoing challenges for municipalities that sit near industrial discharge points.

Controlling the impact of 3-Chlorophenol starts with stronger regulations around discharge and improved technology for breaking down phenols before they reach the environment. The industry has started to look at advanced oxidation methods, using ozone or ultraviolet light, which break down chlorinated phenols more effectively than traditional filtration. I’ve seen local treatment facilities move to such approaches, but these come at a higher cost, especially for small towns. It’s an area where public pressure—along with careful monitoring—keeps the conversation alive. On a personal level, using fewer products with aggressive disinfectants and making sure proper disposal happens can limit unintended release into the environment. Knowledge of the chemical’s structure isn’t just academic; it guides decisions that ripple outward to people and the planet.

3-Chlorophenol isn’t just another chemical on the shelf. Working with chemicals for years, I’ve learned that mishandling substances like this creates dangerous situations in seconds. 3-Chlorophenol brings risks: it’s highly flammable, harmful if inhaled or absorbed, and can irritate the skin and eyes. That adds up to a chemical you always want to treat with more respect than complacency. Improper storage leads to leaks, fires, or worse—emergencies nobody wants in their facility or lab. The peace of mind from getting storage right isn’t just about following the rules. It means your team finishes their shift safely and your workplace meets the standards good professionals expect.

This chemical should be kept in a cool, dry spot. High temperatures increase vapor pressure in the container, heightening flammability and the risk of container rupture over time. Humid conditions promote corrosion around storage vessels, especially if metal is involved. Glass offers a reliable option, and certain high-density plastics can work, but rusty or degraded containers shouldn’t be in use. Storing it away from sunlight is a must—UV light not only degrades the compound but can induce pressure changes or unexpected reactions. I’ve witnessed labels curl and warning marks fade on containers left in sunlit storage, which causes trouble down the road during inventory checks or inspections.

Ventilation takes priority in storage design. Even slow leaks can fill closed spaces with noxious vapor. Anyone opening a storage closet gets a faceful of hazardous fumes, no matter how careful they are, if the air exchange isn’t adequate. Flammable vapors floating in the air spell disaster if there’s a spark or static. Storing 3-Chlorophenol in flame-resistant chemical storage cabinets, built with ventilation ports designed for chemical fumes, provides real protection. The best set-ups include spill containment trays or secondary containers, so even if a bottle tips, the chemical won’t spread across the floor.

Chemical compatibility charts remain a constant reference on my wall. 3-Chlorophenol doesn’t belong anywhere near oxidizing agents such as peroxides or strong acids. If these materials touch, a violent reaction will follow. Store it on a separate shelf, ideally divided by a physical barrier, from reactive substances. If your setup groups everything together “for convenience,” eventually someone pays for the shortcut with an emergency response. Separate lockers, clear labeling, and color-coded bins provide insurance against such mistakes.

Clear labeling makes everyone’s job easier, from newcomers to long-time staff. I use lab-grade markers for labels and include the chemical name, concentration, and hazard warnings. Expiry dates cut down on old, unpredictable chemicals. Training staff to recognize the hazard symbols and keep safety data sheets nearby fosters a safety culture that goes beyond compliance. Gloves, goggles, and sometimes respirators belong standard for anybody who opens a container.

I’ve seen facilities skip steps or cut corners, often because “nothing’s happened before.” That mindset doesn’t hold up under scrutiny. Routine inspections, documentation, and strict adherence to established protocols carry serious weight. A single incident costs time, health, and legal headaches. Raising the standard for storage keeps people safe, products stable, and reputations intact. Secure storage for 3-Chlorophenol is never optional. It’s a promise to the team and to the wider community that safety stands above convenience.

3-Chlorophenol comes up in quite a few conversations about industrial safety and environmental health. This chemical finds its way into workplaces where disinfectants, pesticides, and antiseptics get made. Most people probably don’t run into pure 3-Chlorophenol on a walk in the park, but those working with wood preservatives, dyes, or pharma might do so. It can also leak out as a byproduct in certain water treatment facilities.

If anyone breathes in or touches 3-Chlorophenol, the body almost always reacts quickly. Headaches, dizziness, and a sharp burning in the throat point to trouble. Splash it on the skin, and someone could feel itching, redness, or even blisters. Eyes can burn or water, sometimes painfully. I think back to a time at an industrial site where a simple slip-up sent a whiff of industrial solvent across the shop. Folks coughing and rubbing their eyes were my first clue that even a small dose packs a punch.

Over months or years, 3-Chlorophenol exposure can start to dig in. It doesn’t quit at short-term symptoms. For workers in manufacturing or agriculture, or people living near contaminated sites, repeated low-level contact can break down parts of the liver and kidneys. Nobody wants chemicals chipping away at vital organs. Some studies highlight increased cancer risk, specifically in the bladder and lymphatic system. Growth problems and nervous system issues can hit children harder if pollution turns up in their water supply.

Chemicals like this often find new routes in accidents and spills, but routine releases matter too. A leaky tank or careless disposal can dump 3-Chlorophenol into soil or streams. Smells kick up because this compound evaporates easily. If the air carries it, people miles away, not just workers, breathe it in. In places where water purification gets sloppy and chlorinated waste builds up, this chemical may show up in the tap.

Problems won’t fade by pretending risks don’t exist. Workers deserve safety training—if you know what can hurt you, you’re less likely to handle things blindly. Good gloves, eye shields, and thick clothing block many health hits before they start. Employers should run heavy-duty ventilation and keep showers handy. The right emergency plan means that if a spill spills, everyone knows the drill. Factories that test the air get a clearer picture of safe levels.

Outside the workplace, communities and regulators can demand regular water and soil screening. People living near high-risk industries need honest updates about the chemicals drifting their way. Strict storage and disposal measures keep chemicals locked in, not leaking out. Laws set limits that work only if regulators check in and enforce the rules.

Moving away from legacy chemicals into safer substitutes takes patience and investment. Safer alternatives can sometimes do the same job, with less fallout. Public pressure helps—neighbors pushing for transparency or cleaner local industries can motivate real change. At home, filter systems rated for chlorinated organics stand as one more layer of defense.

Staying informed matters. Clear communication between doctors and patients, community groups and officials, or shift workers and foremen brings hidden threats to the surface. Health isn’t something to bargain with for a little convenience. People stay healthier when industry, government, and neighborhoods all value prevention over clean-up.

| Names | |

| Preferred IUPAC name | 3-Chlorophenol |

| Other names |

m-Chlorophenol m-Cl-Phenol 3-Hydroxychlorobenzene m-Chlorohydroxybenzene Phenol, 3-chloro- |

| Pronunciation | /ˌθriːˈklɔːrəˌfiːnɒl/ |

| Identifiers | |

| CAS Number | 108-43-0 |

| Beilstein Reference | 1209226 |

| ChEBI | CHEBI:34109 |

| ChEMBL | CHEMBL15936 |

| ChemSpider | 682 |

| DrugBank | DB02671 |

| ECHA InfoCard | 100.004.601 |

| EC Number | 3.1.1.296 |

| Gmelin Reference | 84253 |

| KEGG | C01574 |

| MeSH | D002756 |

| PubChem CID | 6959 |

| RTECS number | CAS642-88-6 |

| UNII | 8KQ21L1P23 |

| UN number | 2021 |

| Properties | |

| Chemical formula | C6H5ClO |

| Molar mass | 128.56 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | phenolic |

| Density | 1.36 g/cm³ |

| Solubility in water | 20 g/L (20 °C) |

| log P | 1.96 |

| Vapor pressure | 0.47 mmHg (25 °C) |

| Acidity (pKa) | 8.39 |

| Basicity (pKb) | 15.0 |

| Magnetic susceptibility (χ) | -69.5×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.551 |

| Viscosity | 2.35 mPa·s (25 °C) |

| Dipole moment | 1.73 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 107.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -107.5 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3516.3 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06 |

| Pictograms | GHS05,GHS06 |

| Signal word | Warning |

| Hazard statements | H301, H311, H331, H315, H319, H373 |

| Precautionary statements | P260, P264, P271, P273, P280, P301+P312, P302+P352, P304+P340, P305+P351+P338, P310, P330, P337+P313, P362+P364, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-0-Acute Toxic |

| Flash point | 79 °C (174 °F; 352 K) |

| Autoignition temperature | 605°F (318°C) |

| Explosive limits | Explosive limits: 1.7% to 12% |

| Lethal dose or concentration | LD50 oral rat 695 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 3-Chlorophenol: "695 mg/kg (rat, oral) |

| NIOSH | CN8400000 |

| PEL (Permissible) | 5 ppm |

| REL (Recommended) | 0.5 mg/L |

| IDLH (Immediate danger) | 50 ppm |

| Related compounds | |

| Related compounds |

Phenol 4-Chlorophenol 2-Chlorophenol 3-Bromophenol 3-Iodophenol 3-Fluorophenol |