Back in the early twentieth century, organic chemists explored hundreds of aromatic compounds, searching for better antiseptics. They landed on 2-phenylphenol almost by accident during a push to synthesize more effective germicides. Once the material hit the laboratory benches, scientists across Europe and North America experimented with it, chasing lower production costs and improved stability in harsh environments. By mid-century, manufacturers took notice, rolling out commercial versions for farms, hospitals, and factories. The post-war boom really cemented its role: industrial-scale producers improved distillation techniques, which helped purify the compound in bulk. In my student days, I handled 2-phenylphenol during basic organic practicals, and our instructors talked about its legacy in sanitation protocols. Its steady rise didn't waver. Even now, the development of cleaner synthetic pathways and stricter environmental standards keep tweaking how folks make and use it.

2-Phenylphenol stands as a white or off-white crystalline powder, often bought in drums or smaller containers, based on the user’s scale. The chemical gives off a distinct, medicinal aroma and tends to settle quickly when mixed with water—making it suitable for surface treatments. Most people recognize it from its use in disinfectants and some fruit coatings, but the compound sits behind the scenes in libraries, clinics, and packing warehouses. Since the molecule is less volatile than strongly chlorinated phenols, it stays put longer after application. This feature drew attention from producers of protective surface products. Folks in pest management, sanitation, and industrial coatings find the compound dependable due to its long history and consistent test outcomes. Daily-life encounters rarely lead to dangerous exposure unless someone misuses concentrated forms.

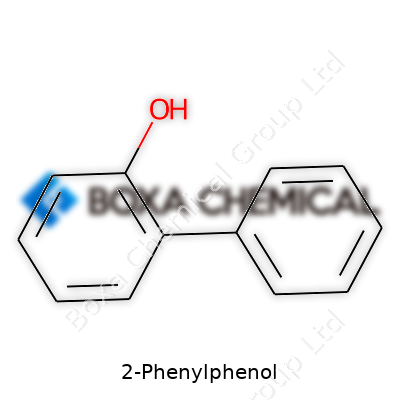

2-Phenylphenol displays a melting range around 56-58°C and boils at roughly 285°C. The material stays insoluble in water but dissolves well in ethanol, ether, and chloroform. The molecule, C12H10O, carries a phenolic hydroxyl group attached to a biphenyl skeleton, which boosts its reactivity toward oxidizing agents. The solid appears slightly glossy under strong light and shows a bitter taste—though direct ingestion is unwise. Under regular conditions, it doesn’t break down or oxidize fast. Exposure to strong acids or bases, though, degrades it into less stable materials. Shelf-life rarely troubles it in sealed packaging.

Producers typically offer 2-phenylphenol with purity exceeding 99%. Labels specify the CAS number (90-43-7), batch code, net weight, manufacture date, and distributor contacts. Some regulatory frameworks require hazard icons for skin and eye risk. On larger drums, labeling rules add specific handling and storage directions, with language matching international transport guidelines. Manufacturers follow quality checks for melting point, residue on ignition, heavy metal content, and assay by HPLC or titration. Strict batch records help buyers trace lots if questions arise about contamination or deviation from the stated purity level. Labels may include pictograms for environmental hazards in regions with tighter discharge restrictions.

Most industrial producers synthesize 2-phenylphenol by coupling benzene with phenol through Friedel–Crafts alkylation. Aluminum chloride acts as the catalyst, pulling electrons to favor the ortho orientation on the phenol. The reaction often unfolds in controlled, inert atmospheres because aluminum chloride reacts violently with moisture. After reaction, the mix goes through a neutralization step with dilute acid to remove leftover catalyst. Solution separation and fractional distillation follow to purify the product. Small-lab approaches use similar chemistry, though safety protocols become even more critical due to the violent nature of the catalyst.

2-Phenylphenol carries a hydroxyl group that opens the door for numerous chemical tweaks. Acylation adds protective groups to improve material stability or tune solubility. Nitration leads to derivatives with altered toxicity and microbicidal power. Hydrogenation and halogenation allow researchers to probe structure–activity relationships. Under oxidative conditions, the molecule can yield biphenyl quinones—compounds of interest in dye and antioxidant research. Even today, fine chemical producers keep exploring alternative modifications to evolve its practical toolkit.

People call 2-phenylphenol by many names, depending on its market or region. In agricultural circles, it often appears as “ortho-phenylphenol” or “OPP.” Some safety data sheets tag it as “biphenylol” or “o-biphenylol.” In Europe, buyers may encounter “Dowicide” or “Preventol” brands. The variety in naming traces the compound’s diverse acceptance across global trade routes. This patchwork of names confuses some first-time buyers, especially when reading older research or regulatory lists, so double-checking chemical identifiers always helps.

Handling 2-phenylphenol calls for eye protection, gloves, and good ventilation. Prolonged skin or eye exposure can lead to irritation. Industrial guidelines, including those set by OSHA, list it as a moderate hazard for direct contact but rarely cause lingering injury unless mishandled. In studies, the material doesn't easily vaporize under working conditions, which lowers inhalation risk. Spills clean up well with absorbent material and should go to chemical waste. Waterways and storm drains need to stay clear of even small residues, due to moderate aquatic toxicity. Emergency procedures recommend washing exposed skin thoroughly and seeking help if irritation persists.

Sanitizers, fruit and vegetable washes, library fungicides, and household disinfectants make heavy use of 2-phenylphenol. Pesticide manufacturers coat citrus fruit, apples, and pears to prevent post-harvest spoilage, especially in transit to docks or grocery stores. The compound keeps mold and bacteria at bay on shipping containers, sorting bins, and retail displays. Transport workers, especially in food logistics, regularly check surface concentrations with spot tests. Hospitals and clinics use diluted forms to wipe down tools and benches, as the material keeps working when surfaces stay wet for extended periods. In public libraries and museums, the compound preserves rare book collections by holding back fungal growth. Over the years, paint producers and adhesive manufacturers have dabbled with it as a biocide in water-based formulations.

Chemists and toxicologists keep probing the best ways to fine-tune the molecule for higher germicidal action and lower residual risk. The last decade brought efforts to develop greener syntheses, swapping out hazardous catalysts for milder, reusable alternatives. Environmental agencies around the world want manufacturers to develop protocols that slash run-off and capture any volatile byproducts. Some academic labs now attach sugar or alkyl chains to tweak solubility in water, aiming for use on sensitive surfaces and food products. Toxicological studies track the breakdown pathways, hoping to understand any metabolites left after environmental exposure. In my professional reading, the scale of collaboration between chemical engineers, environmental scientists, and regulatory experts stands out, especially in major pesticide-exporting countries.

Scientists have spent decades reviewing how 2-phenylphenol interacts with animal and human tissue. Studies show low acute toxicity for mammals in doses typically encountered during commercial use, but extended or unusual exposures increase irritation and, in some rare cases, allergic reactions. When used on fruits, washing with water and common surfactants removes nearly all surface residues. Regulators keep tabs on tolerable daily intake for populations most exposed—farm workers, food processors, and cleaning staff. Animal studies run for multiple generations haven't flagged alarming risk at attributed workplace doses, but aquatic organisms can see disruption at much lower levels. Recent reports focus on breakdown products in soil and water, which can linger if not promptly neutralized. Because food safety laws in many countries take a conservative stance, products with 2-phenylphenol get regular reevaluation as toxicology databases expand.

Producers face mounting pressure to trim waste and limit any ecological fallout. Green chemistry labs now experiment with catalysts that shrink dangerous emissions, while recycling processes close the loop on every gram manufactured. Research teams push for less persistent derivatives, hoping to keep the biocidal punch but cut environmental half-lives. Public health officials keep scouring the data for any signs of shifting risk–benefit balances in consumer products. Next-generation surface coatings may entwine the molecule in deeper matrices to slash migration into treated goods. Scientists also watch for microbial resistance, just as they do with antibiotics, since overuse could dent long-term usefulness. In the coming decade, balancing worker safety, food shelf life, and minimal environmental impact drives the research agenda—all under the watchful gaze of agencies, advocacy groups, and an educated public demanding better answers and bolder safety standards.

2-Phenylphenol sounds like a niche chemical, but chances are it's already quietly slipped into your life. Visit the produce section at the supermarket. The glossy fruits, especially imported citrus, get their shine from wash solutions containing this compound. The reason: it keeps mold and bacteria off oranges and lemons during storage and transit. Retailers want unblemished fruit, and many shoppers reach for the fruit that looks least likely to spoil at home.

Find a cleaning aisle in the same store. Look closely at the labels of some household disinfectant sprays and wipes. Certain formulas tout “antibacterial” or “hospital-grade” protection, and that’s where 2-Phenylphenol earns its place. Hospitals, offices, and even restaurants count on this substance to attack germs on hard surfaces and equipment.

Public health outcomes depend heavily on sanitation. The world watched disease outbreaks spread via contaminated surfaces, not just foodborne illnesses but viral threats as well. Disinfecting agents like 2-Phenylphenol step in with broad-spectrum power. Fewer bacteria on kitchen counters or medical gear means less risk to families and healthcare staff. On the farm, mold can ruin citrus crops and wipe out profit as quickly as a bad hailstorm. Fungicides like this step in as a line of defense for growers. The cost of losing half a crop could ripple through food supply chains and even drive prices up at the checkout.

Once a tool is trusted, the temptation to overuse it grows. This chemical may linger on fruit skin, though common washing at home strips most traces away. There remains some worry about residues, especially for people eating large amounts of treated produce. Regulatory groups, including the World Health Organization, set strict limits for these residues. Still, the question surfaces: do consumers care what lines their apples and oranges? Are alternatives, like advanced storage methods or biopreservatives, just as effective?

Some cleaning staff react after touching products containing this chemical. Not as many people are sensitive to it as to bleach, but skin and eye irritation is an occasional hazard. Ventilation and gloves help, yet the routine use in shared workspaces means someone may always be exposed. Tracking these reactions shouldn’t fall just to the manufacturers. Employers and regulators need to listen and update safety guidance as new information comes out.

2-Phenylphenol solves real problems for food safety and sanitation. At the same time, society can’t ignore the pressure to use less chemical intervention in daily life. Stores could offer more uncoated or organic fruit selections. Businesses and hospitals might rotate among different cleaning agents to reduce chemical exposure and slow down germ resistance. As a parent, I’ve scrubbed fruit, weighed the odds, and decided once in a while to buy unwaxed produce from the local farmer. In any setting, asking what’s on your food and in your home products opens the door to better choices. Everyone benefits when industries respond to these questions transparently, with clear, evidence-backed information available to the public. The conversation about 2-Phenylphenol isn’t only about risk, but about keeping the power of choice in the hands of those who need it every day.

2-Phenylphenol often shows up in places most people wouldn’t think to look, from the surface of fruit stored for supermarkets to bathroom cleaners and hospital disinfectants. This compound kills mold, tackles bacteria, and even wards off spoilage on lemons and oranges during long journeys from farm to fork. The average person may never realize how commonly it pops up.

As someone with allergies and skin sensitivities, I always keep an eye out for ingredients in household products. Over the years, I’ve learned that 2-Phenylphenol can cause irritation for certain people. The U.S. Environmental Protection Agency (EPA) backs this up. Short-term exposure sometimes bothers the skin, eyes, or respiratory system. Most grocery shoppers never notice since residue levels on food get measured and regulated heavily. That said, stories of skin rashes from direct contact aren’t so rare, especially among workers who handle disinfectant wipes, sprays, or produce coatings day in and day out.

The World Health Organization (WHO) and the U.S. Food and Drug Administration (FDA) both say it’s not a carcinogen at the typical residues seen on food. OSHA also sets work safety levels, because repeated or heavy use carries its risks. Cases in factories and packing plants highlight the need for gloves and good ventilation. As long as safety guidelines get followed, problems rarely reach the public, but that’s only part of the picture.

People care about what goes into the cleaners they use at home and what ends up on their fruit salad. Even though experts agree that 2-Phenylphenol breaks down quickly and doesn’t build up in the body, the idea of chemical coatings on fresh produce gives many pause. It’s not just about actual risk—it’s about trust and choice. A label tucked away isn’t the same as clear, up-front disclosure at the grocery store.

Better transparency can bridge this trust gap. More stores now take the lead by explaining how produce gets treated, and what the labels really mean. Organic certifications, for example, strictly prohibit 2-Phenylphenol and related chemicals. Those who want to avoid it can often do so, but only if information is available.

In homes that rely on disinfectants for cleaning, using gloves helps prevent skin irritation. Proper rinsing and following manufacturers’ instructions matters more than most realize. With fruit, a good wash under running water removes most residue. For those especially sensitive or concerned, peeling citrus fruit before eating provides further peace of mind.

At the workplace, protective gear and well-maintained ventilation keep risks manageable. Regular safety training ensures no one gets exposed due to carelessness or lack of information.

Safer substitutes keep hitting the market, and some companies already focus on plant-based disinfectants in place of traditional chemicals. As more people push for clean labels and gentle ingredients, research and regulations continue to shift. Fact-based decisions and open communication help keep everyone safe—at home, at work, and at the grocery store.

Stepping into a lab, 2-Phenylphenol would probably draw a few glances. Its crystals flash white or nearly white, and the lack of color can catch people off guard considering how potent the compound actually is. Any chemist handling it quickly finds that it carries a mild, almost floral odor, nothing sharp or overwhelming—just a gentle reminder of the aromatic rings in its structure.

At around 57 to 59 degrees Celsius, those neat white crystals start giving way to a clear liquid. The melting point matters for handling and storage, and it helps manufacturers decide how to process and ship the material. The boiling point sits up at about 305 degrees Celsius. Factories working with it need strong ventilation and solid safety measures because once heated up, it can move into vapor form, which people working nearby need to know about. The boiling point also impacts which applications make the most sense in chemical syntheses or disinfection.

Some folks might try adding it straight into a water solution expecting a quick dissolve, but 2-Phenylphenol refuses. It barely dissolves in water, with a solubility of less than 0.1 g per 100 mL. That trait pushes companies to look for alternatives, most often organic solvents. It blends pretty well with alcohol, acetone, ether, and chloroform, which signals its suitability for industrial uses or lab extractions. Certain cleaning products or preservatives avoid water carriers for this reason and instead use alcohol-based solvents or oil suspensions.

Experimenting with 2-Phenylphenol, one takes note of its resilience at ambient conditions. Dry, tightly sealed, and away from intense sunlight, it’ll stay stable for quite a while. Direct flames and strong oxidizers still present real risks. The compound’s low volatility at room temperature means you won’t usually find the lab filled with its scent or dealing with rapid losses to the atmosphere. That gives a sense of security for storage, but storing it badly could turn safety into a guessing game.

Pour out a sample, and you’ll find it denser than water, at about 1.25 g/cm³. Spills, if not addressed, won’t float—they’ll stick to surfaces or sink in mixed liquids. Anyone cleaning up needs to remember that. The density also means equipment needs regular checks for buildup, especially when dealing with slurries or recirculating systems in industrial setups.

2-Phenylphenol’s properties give it roles in disinfectants, fungicides, and preservative products. The low water solubility leads some producers to push for more environmentally sensitive alternatives or improved handling processes. Reliable solvents remain a must for those making concentrated solutions, and solid PPE—think gloves, masks, goggles—keeps workplace exposure to a minimum. Regular testing for residue and vapor, plus careful disposal, helps companies handle risks before they get out of hand. Anyone working with this compound stays mindful of these physical traits, since knowing the limits can be the difference between efficient, safe use and surprise mishaps.

Anyone who’s ever handled cleaning agents or certain disinfectants has probably come across 2-Phenylphenol. This white or light-colored powder works as a preservative and cleaner, found in homes and industries. Its widespread use often hides the real risks. Mishandling chemicals, even the familiar ones, sometimes seems harmless—until a spill or reaction catches you off guard.

Experience with chemical supplies in a small maintenance workshop taught me that trusting manufacturer containers too much can bring trouble. Cardboard deteriorates in damp spaces. Lids get swapped or loosened. Once, a mild leak from an improperly sealed pail led to harsh fumes filling the back room, sending a co-worker home with a headache. A clear chemical like 2-Phenylphenol may seem indifferent to its surroundings, but air, light, and moisture all stir up risks over time. The powder can clump, degrade, or interact with whatever it meets.

Direct experience shows crowded utility rooms invite problems. Storing 2-Phenylphenol somewhere damp or stuffy almost always leads to trouble. Aim for dry and cool spots. Temperatures that swing between hot and cold encourage condensation, which breaks down powders quickly. On a few commercial sites I’ve visited, containers set by exterior walls or near open windows seemed to age faster and sometimes smelled harsher, especially after rain or humidity spikes.

Storing bulk or small amounts in solid plastic or glass containers works best. Resealable lids keep out both moisture and dust. Ordinary boxes or bins, no matter how sturdy, fail to block fumes sneaking into the air. Over time, inhalation—even in small quantities—brings headaches and possible breathing problems. Lockable cabinets with good circulation don’t just tick off a safety box: they genuinely make the workplace more liveable.

True safety means paying attention to what you store nearby. Strong acids and bases stored next to 2-Phenylphenol guarantee disaster with the slightest mix-up. My time working in a community hospital’s janitorial supply room showed countless unlabeled bottles and open pails—one accidental spill and you get a chemical soup that’s a nightmare to clean up. Keep 2-Phenylphenol isolated from other volatile substances and combustibles. Shelves should bear clear, unfaded labels.

Reading a date-stamped label or clear hazard sign should become a habit. Rotating stock, checking for damaged packaging, and updating logs go much farther than an occasional glance. Small efforts here add up. Once, an undetected crack in an old bottle ruined a week’s supply of nearby stock in a grocery backroom. People tend to forget—chemicals aren’t forgiving.

Leftovers, outdated stock, or accidental spills happen. Keep a standard clean-up kit nearby: gloves, absorbent material, and a safe disposal plan. Leaving containers half-used or unsealed means chemicals evaporate, leak, or spill—costing real money and health. Local fire codes and environmental laws back these steps for good reason. No shortcut makes up for a lack of planning.

Reliable storage for 2-Phenylphenol starts with informed respect, not just rule-following. Personal experience, regular oversight, and basic common sense prevent most problems. A few extra minutes spent on storage pay off, keeping your space—and everyone in it—safe from unexpected headaches, messes, or worse.

2-Phenylphenol often pops up on labels for disinfectants, preservatives, and fungicides. You might spot it listed as an active ingredient in household cleaners or even find traces left behind on citrus fruits. It works as a reliable germ-killer, which makes it valuable to industries and consumers alike. Despite its benefits, too few people talk about what this chemical does to the body under frequent or careless exposure.

Years back, I helped on an orange farm during a summer job. We used solutions to wash the fruit, aiming to knock out mold before shipment. Only later did I pay attention to warnings about using gloves and working in well-ventilated areas. Shoppers who pick up lemons or limes at the grocery store might not realize that 2-phenylphenol—under the guise of food-grade preservative—lingers on that shiny skin.

People who use household cleaners with 2-Phenylphenol on a daily basis, especially in closed spaces, could face higher risks. Janitors, farmers, and workers at food processing plants get the most exposure, but everyone chipping away at stubborn grime with disinfectant has some chance of absorbing or inhaling this chemical.

Research has shown that skin, eyes, and the respiratory system often react to this substance. Chronic skin contact may lead to irritation, itching, or rashes. Breathing in heavy fumes irritates the nose and throat and causes coughing or breathing troubles. In recorded cases, eye splashes produce prompt redness or burning sensation.

Digging deeper, animal studies found that high doses affected the liver, kidneys, and even showed signs of carcinogenicity. The International Agency for Research on Cancer put 2-phenylphenol in Group 2B—possibly carcinogenic to humans. Evidence for cancer risk in people who encounter it is still murky, but that uncertainty leaves me feeling cautious, not dismissive.

Young children tend to put hands in their mouths after touching surfaces, which means any residue on kitchen counters or tables could find its way into their bodies. For people with asthma or other lung trouble, airborne particles only complicate breathing. Eye protection and gloves quickly go from nice-to-have to must-haves for those working around concentrated solutions.

Reading a bottle’s fine print often helps you dodge unnecessary dangers. Wearing gloves and opening windows while cleaning goes a long way to keep risk low. If you buy citrus fruit, washing peels under running water before eating or zesting can knock off most of the residue. At work, companies ought to substitute safer options where possible and train people to handle dangerous chemicals with respect, not indifference.

Regulators have a role. Reevaluating acceptable use, updating labeling rules, and requiring clearer warnings can help regular people stay safer. Medical research always needs support, both to learn what real-world risks look like and to shape better guidelines down the road.

After handling chemicals like 2-phenylphenol, hand washing matters more than ever. The habit takes little effort but shields against unseen threats. Community education can spark real change by helping the public spot these hazards before harm occurs. A little vigilance makes a difference, whether you clean offices or buy oranges for lunch.

| Names | |

| Preferred IUPAC name | 2-phenylphenol |

| Other names |

o-Phenylphenol Orthophenylphenol o-Biphenylol 2-Hydroxybiphenyl |

| Pronunciation | /tuː-ˈfiːnəl-ˈfiːnɒl/ |

| Identifiers | |

| CAS Number | 90-43-7 |

| Beilstein Reference | 1209226 |

| ChEBI | CHEBI:31772 |

| ChEMBL | CHEMBL14147 |

| ChemSpider | 13856152 |

| DrugBank | DB13822 |

| ECHA InfoCard | 03d4505e-a248-4162-90b8-8c369d9a996e |

| EC Number | 201-993-5 |

| Gmelin Reference | 82280 |

| KEGG | C06577 |

| MeSH | D010575 |

| PubChem CID | 6973 |

| RTECS number | SX3150000 |

| UNII | 1N8EUY8F07 |

| UN number | UN3077 |

| Properties | |

| Chemical formula | C12H10O |

| Molar mass | 170.21 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.25 g/cm3 |

| Solubility in water | 1.2 g/L (20 °C) |

| log P | 3.3 |

| Vapor pressure | 0.001 mmHg (25°C) |

| Acidity (pKa) | 9.58 |

| Basicity (pKb) | 9.58 |

| Magnetic susceptibility (χ) | -16.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.613 |

| Viscosity | 17 mPa·s (20 °C) |

| Dipole moment | 2.33 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 150.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -4.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4707.7 kJ/mol |

| Pharmacology | |

| ATC code | D08AE02 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS09 |

| Signal word | Danger |

| Hazard statements | H302, H315, H318, H410 |

| Precautionary statements | P264, P280, P305+P351+P338, P337+P313 |

| Flash point | 113°C |

| Autoignition temperature | 170 °C (338 °F; 443 K) |

| Lethal dose or concentration | LD50 oral rat 2700 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 2700 mg/kg |

| NIOSH | ZE2450000 |

| PEL (Permissible) | 5 mg/m3 |

| REL (Recommended) | 0.2 mg/L |

| IDLH (Immediate danger) | 250 mg/m3 |

| Related compounds | |

| Related compounds |

Phenol Biphenyl o-Cresol 2-Phenylphenol sodium salt 2,4-Dichlorophenol |