People first drew up the rough outlines of brominated phenolic chemistry near the turn of the 20th century. Synthetic work from early European labs focused on simple phenols and halogenated derivatives, and the development of 2,4,6-Tribromophenol (TBP) followed this path. By the middle of the last century, demand for flame retardant materials in building and electronics grew, and research into brominated organic compounds began to increase sharply. Chemists leaned on the relatively forgiving reactivity of phenol with bromine under mild conditions, producing compounds like TBP efficiently. The industry's appetite for plastics continued to grow, and TBP stepped up as both an intermediate and an end-use product in a range of flame-retardant technologies. In practical terms, factories and research outfits started pumping out metric tons of the stuff, and it wasn’t long before its unique properties—and associated risks—became understood.

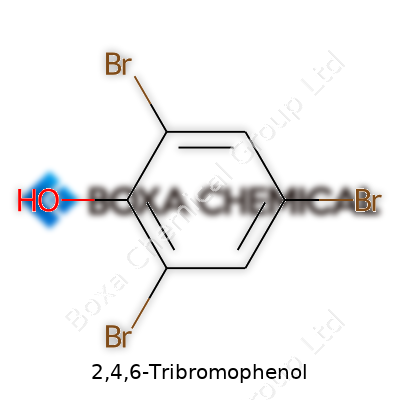

2,4,6-Tribromophenol, recognized under the CAS number 118-79-6, presents itself as a pale white to off-white crystalline solid. It gives a sharp, slightly medicinal odor and finds its way into applications touching electronics, textiles, and biocides. In industry, folks use it most heavily as a reactant for fabricating other brominated compounds, especially flame retardants and plastic additives. It also shows up in fungicidal treatments and wood preservatives, thanks to its chemical backbone, which resists microbial attack. Research labs and chemical suppliers both stock this material in multiple purities, usually packaged in air-tight containers to ward off ambient moisture. Its importance comes from a mixture of reactivity, relatively straightforward handling, and a proven track record as an industrial unlock for safer materials.

TBP sits on the bench as a crystalline powder with a melting point around 95–97ºC and a boiling point over 270ºC under normal pressure. It barely dissolves in water but loves organic solvents such as ethanol, ether, and chloroform. Thanks to its high degree of bromination, it carries a density above 2.7 g/cm³, packing more molecular weight for the buck. TBP shows strong reactivity because the triple bromine substitution on the ring alters its electron distribution; this makes it less susceptible to oxidation but very eager to act as a synthon in coupling and condensation reactions. The compound’s stability at elevated temperatures also means it resists degradation in polymers and coatings—one reason plastics manufacturers keep coming back to it.

Chemical distributors typically ship TBP labeled with hazard pictograms, UN numbers, and safety warnings about handling and storage. Standard purity levels run from 98% upwards, plenty clean for industry and most lab work. People working with the substance check for foreign particulates, color, and moisture content. Specifications spell out acceptable impurity thresholds, focusing on related bromophenols, residual bromine, and water content; these specs matter because impurity levels alter downstream reaction efficiency and safety. Labels include manufacturer details, batch numbers, date codes, and recommended storage at cool, dry, and well-ventilated places.

Most TBP comes from direct bromination of phenol, a process almost every commercial chemist has tackled in one form or another. In its basic setup, phenol mixes with elemental bromine or a bromine-liberating reagent. The reaction usually runs in water or an organic solvent, often with a mild base to draw off the hydrogen bromide byproduct. Temperature control is critical. Too much heat pushes the reaction to unwanted side products; too little, and yields drop. After completion, workers isolate TBP by filtration or crystallization, followed by washing and drying processes that matter for the purity and performance of the product.

The unique ring structure of TBP opens several doors for functionalization. Coupling reactions, notably those involving aryl halide chemistry, leverage the activated ortho-bromo positions, pushing TBP into the ranks of designer molecular building blocks. Nucleophilic substitution and condensation expand its relevance, letting chemists swap out the -OH or add to the ring at open slots. Reacting it further with strong bases makes for sodium or potassium salts, tweaks often requested for custom polymer applications. People running research on environment-friendly chemistry have even tried debromination routes, seeking ways to reclaim or upcycle spent TBP in industrial waste.

In trade books and chemical catalogs, TBP answers to many names. Regulars will call it 2,4,6-Tribromophenol, but it also goes by TBP, phenol, tribromo-, phenol, 2,4,6-tribromo-, and sometimes 2,4,6-TBP just for brevity. The language reflects the practical, no-nonsense nature of chemical commerce. Globally, product registrations might list its name in multiple scripts, ensuring that plants, customs, and field workers can all identify the material in a pinch. The naming conventions tie into international transport and regulatory compliance, keeping people on the same page across supply chains.

Handling TBP requires focus and proper gear. The compound acts as a skin and respiratory irritant. Inhalation or contact can set off acute reactions, so gloves and masks aren't optional. Workers rely on established Material Safety Data Sheets and follow national regulatory rules, such as OSHA’s standards in the U.S. or REACH in Europe. Waste management and spill protocols stand front and center, because TBP’s persistence in the environment raises red flags in safety training. Lab and plant managers use closed systems or local exhaust to keep fumes away, with eye-wash stations and first aid kits close by just in case. Storage calls for airtight seals, low humidity, and clear labeling—a small price to pay for safety.

You’ll spot TBP most often where fire resistance counts for more than appearance. It strengthens resins, coatings, and high-performance plastics meant for electronics housings and household insulation. Many folks in the wood treatment sector appreciate TBP’s biocidal punch, which preserves lumber from rot and termites. The chemical’s reactivity lets it play chameleon, taking on life as precursor to a range of brominated flame retardants and fungicides. In textile finishing, TBP's value lies in its robust behavior—holding up to multiple industrial washings while still providing rear-guard flame protection. Agrochemical and marine coatings fields have both put TBP to work, leveraging its technical and biological features where standard treatments would otherwise fall short.

Chemists and material scientists keep exploring ways to make TBP cleaner, safer, and greener. With environmental regulators keeping a close eye on persistent organic pollutants, research outfits now chase greener synthesis routes, cutting down on waste and energy usage. Some teams have tested bio-catalyzed bromination or alternative solvents, searching for lowered toxicity and more sustainable processes. Universities and startups dive into TBP’s utility in advanced electronics, looking for molecular tweaks that bring new flame retardant standards or improved polymer properties. Every advance means higher safety margins or lower environmental footprints on plastics and composites.

Studies show TBP sticks around longer than many simple organics, raising issues in both workplace and ecological contexts. Toxicology research digs deep into how chronic exposure impacts organs or hormonal systems in mammals. TBP can accumulate in water or soil, endangering aquatic life and making its way up the food chain. Some lab assays point to mild carcinogenicity, though results shift based on test conditions. Regulators across Asia, Europe, and the Americas base occupational exposure limits on these findings. Developing better monitoring and remediation tech remains a big focus, as folks weigh TBP’s indispensable utility against its demonstrated risks.

The chemical’s fate will turn on safer synthesis, resource recovery, and new uses in high-value markets. Sustainable chemistry movements press manufacturers to choose raw materials and processes with smaller ecological footprints, driving interest in reuse tech and degradable flame retardants. Industry might see TBP linked to new biodegradable polymers, or treated with additives that limit its leaching and persistence. Digital controls and sensor systems in modern plants promise to reduce emissions, bringing TBP handling more in line with community health priorities. In applied science, the next frontier for TBP-based compounds may come in electronics, coatings, or smart textiles—attracting investment where safety and performance go hand in hand.

2,4,6-Tribromophenol looks like an obscure chemical to most people, sitting in the background of industrial supply chains and only known to a handful of specialists. On paper, it’s a white, crystalline substance. In real life, it has a footprint that stretches from electrical goods to the conservation of shipping materials. Working in environmental consulting, I came across it during a factory audit and soon realized how many everyday items cross paths with this compound, even if people never see it on a label.

The main job for 2,4,6-Tribromophenol comes from its flame-retardant properties. It gets blended into plastics, resins, and circuit boards. Picture an appliance like a hairdryer or a TV, maybe even your old desktop monitor. Many of these items depend on chemicals like this to slow down fire if something overheats. In the real world, a few extra seconds in a fire can save a lot of lives and property. Brominated flame retardants often carry the heavy load in these situations. Fact: in one study, about a quarter of consumer plastics carried some type of brominated fireproofing compound.

Another job falls in the world of preservation. 2,4,6-Tribromophenol keeps mold and fungus out of wood, textiles, and paper. Shipping crates, pallets, stored fabrics, and even some specialty papers receive this treatment. Mold grows fast when there’s a little heat and humidity, so exporters and importers often look for strong chemicals to stretch shelf life and meet regulations. As a field inspector for a major logistics company, I often saw this chemical in warehouses storing tropical hardwood, especially lumber headed for countries with tough pest-control standards.

Industrial chemists use 2,4,6-Tribromophenol as a raw material to make other complex molecules, including some antiseptics, photographic chemicals, and flame-retardant ethers. Chemists like synthesizing from a stable, well-understood structure. Over the years, a lot of routine chemical engineering rests on the back of such intermediates. According to market reports, demand for this product often rises or falls with changes in electronics or construction, two sectors tied to infrastructure and economic cycles.

Jobs bring responsibilities. One big concern: brominated chemicals, including this one, don’t break down fast in the environment. Some studies link them to hormone changes in wildlife—especially aquatic species that live downstream from plants, or in harbors that leach materials from treated wood. In my own work tracking water samples near old dockyards, residues from chemicals like this lingered long after their intended use. Health experts believe chronic exposure may pose risks, especially during the manufacture and recycling of electronics or furniture.

Safer alternatives to brominated flame retardants are already in development, using phosphorus or even natural compounds from minerals and plants. Recyclers and manufacturers can also improve their safety culture by fitting plants with proper scrubbers, monitoring airborne dust, and separating chemical-laden scrap before recycling. For wood and textiles, less-toxic biocides and controlled storage conditions help cut dependence on chemicals like 2,4,6-Tribromophenol. As governments tighten regulations, companies find practical ways to switch chemicals, protect workers, and reduce leaks to soil and water.

I’ve seen plenty of chemical safety sheets, and honestly, many get tossed aside for being dull. But 2,4,6-Tribromophenol deserves real attention. This brominated phenol packs a punch, both in its applications and its health risks. If you breathe it in, swallow it, or let it soak through your skin, you’re setting yourself up for trouble. Eyes and skin start itching. Lungs burn. Stomach flips. Don’t just brush these effects off as typical—this compound can do damage over years of repeated use.

Relying on hope and a lab coat won’t cut it. Nitrile or neoprene gloves create a solid shield. Forget the thin single-use ones; they barely stand up to the compound. Splash-proof goggles stand between you and lingering eye irritations. A tight lab jacket prevents skin exposure, and a proper fitted respirator offers protection from fine dust. Cotton clothes alone just trap the powder. The phrase “dress for the job” takes on new weight around this stuff.

Ventilation stops fumes and dust from hanging around. Hoods or well-designed extraction systems mean less chance of breathing in airborne particles. These aren’t just investment pieces—they save on healthcare bills down the line. Rooms without working exhausts end up as silent hazards turning a simple handling job toxic.

This isn’t like flour or sugar on a kitchen counter. Any spill should get handled with a dedicated spill kit. Loose powder travels quickly. Wet down spills before cleaning to prevent dust clouds. A HEPA vacuum works best—never sweep or use compressed air. Rags, gloves, or cleaning supplies should never go back in ordinary trash. Use marked containers, and get hazmat-trained people to handle disposal. These details matter, and anyone who’s ever had to clean up a poorly managed lab knows what a nightmare leftover residues become.

You cannot count on luck—not over months or years. If it gets in your eyes, rinse for a good 15 minutes and see a doctor. For skin, take off any contaminated clothing right away, then wash up thoroughly. Breathing problems or stomach aches after an accident mean you should seek medical help, even if symptoms fade at first. Reporting exposures to supervisors and medical staff lets your workplace adapt and put in extra controls where accidents keep happening. Training sessions help, but real stories of accidents drive the message home far more effectively.

2,4,6-Tribromophenol shouldn’t end up on breakroom tables or mixed with food and drink. I’ve seen accidents where cross-contamination sent people to urgent care. Label everything, store it away from acids and heat, and use double containment. Lock it up if you’ve got high-traffic labs or shared workspaces. More eyes on the supply means fewer mistakes and less temptation for shortcuts.

No single rule works for every spot. The places that stay safe usually combine vigilant staff, clear rules, and well-stocked safety gear. Regular inspections catch bad habits before they escalate. Anyone handling 2,4,6-Tribromophenol can speak up if they spot shortcuts or missing equipment, and leadership has to respond. Routine doesn’t mean careless. Chemicals like this reward careful, consistent handling with long-term good health—not just for the worker, but for everyone nearby.

2,4,6-Tribromophenol has the chemical formula C6H3Br3O. The name hints at its structure—a benzene ring, three bromine atoms, and a single hydroxyl group. Every corner of that formula has a story. The three bromines attached to positions 2, 4, and 6 of the benzene ring tell us how this molecule behaves in the real world, not just in a textbook.

Seeing a formula as dry data loses the bigger picture. Working with chemicals in a college lab, handling compounds like this pushed me to learn more about safety than just memorizing acid-base reactions. That’s because 2,4,6-Tribromophenol doesn’t act like plain phenol. The bromine substitutions change not just the reactivity but also the molecule’s effect on living things and the environment. According to the European Chemicals Agency, this compound can persist in nature, building up over time, and may even show up in unexpected places like household goods or ocean sediments.

Adding those three bromines isn’t just for fun. Brominated phenols like this one find use in flame retardants and wood preservatives. In manufacturing, the environmental impact gets overlooked for the immediate benefit. In high school, I volunteered at a science museum where discarded electronics, loaded with brominated compounds, ended up on display as examples of both innovation and pollution. Once released, these molecules don’t just vanish. They stick around, entering everything from soil to our water supplies.

Scientists from the Journal of Hazardous Materials have found residues of 2,4,6-tribromophenol in export timber or near e-waste recycling zones. Such findings show how easily a chemical’s formula translates into real-world consequences. The World Health Organization lists phenolic compounds—including brominated ones—among substances that can cause acute and chronic health issues depending on the dose and duration of exposure.

Knowing what C6H3Br3O stands for matters. It’s a wake-up call for folks developing new materials or managing waste. My own experience in environmental science classes always circled back to one thing: every synthetic chemical, no matter how useful, has a pathway in nature. We can’t ignore the persistence of 2,4,6-Tribromophenol just to make fireproof coatings or preserve timber. Waste handling programs, stronger workplace safety practices, and alternative green chemistry solutions help limit harm. Industry innovators like the Green Chemistry movement stress replacing toxic halogenated compounds with benign substitutes whenever possible. That work takes commitment, but it pays off through safer workplaces and healthier communities.

If you’re handling chemicals or studying them, don’t let a formula’s simplicity fool you. Programs that track and recycle halogenated compounds matter just as much as tightening regulations. Anyone who has cleaned up after a chemical spill knows one small action can ripple out to protect an entire ecosystem. Every detail, from those three bromine atoms to how the waste is managed, deserves attention. Otherwise, the environment will remind us later.

2,4,6-Tribromophenol—a mouthful for anyone outside the chemistry lab—is a common ingredient in flame retardants and wood preservatives. Over the years, I’ve seen more of these chemicals end up in household products, from furniture to electronics. Most people never think about the complicated names listed far down the label, but the reality behind them deserves closer attention.

In daily life, exposure can happen by touching treated wood, inhaling dust indoors, or, less often, through water near factories using this compound. Research has shown it doesn’t just stay where it’s put. Scientists have tracked 2,4,6-Tribromophenol in the air and in water, and even in food packaging. I remember a study where fish in rivers near manufacturing plants carried traces of it in their bodies. That puts people who eat those fish at risk, often without knowing it.

Animal studies point to effects on the liver and thyroid. The liver gets called in to process unwelcome chemicals, but can get damaged in the process. There’s concern about this substance messing with hormone systems—the thyroid, in particular, can throw the whole body off if it doesn’t work right. The International Agency for Research on Cancer hasn't labeled it as a known carcinogen yet, but the evidence isn’t reassuring either.

It doesn’t break down easily in the environment. Once it gets into soil or waterways, it hangs around. I found out that some brominated compounds travel up the food chain, showing up in animals far from the original source. There’s evidence linking persistent, bioaccumulative chemicals like this to declining bird and fish populations. As someone who enjoys fishing and hiking, watching clean streams get polluted feels personal. We can’t undo the harm easily once these chemicals enter the system.

Because 2,4,6-Tribromophenol resists breakdown, it’s even been detected in remote areas, much farther from factory sites than most folks would expect. That speaks to how much we underestimate the spread of industrial pollutants. Microorganisms in soil struggle to degrade it, so it sticks around for years, sometimes decades.

The easiest way to cut risk is to limit use. Flame retardants save lives, but safer alternatives exist. Regulators in Europe have tightened oversight over brominated flame retardants, pushing industries toward less persistent chemicals. When California strengthened its flammability rules, some manufacturers swapped out heavy chemicals for safer ones. Clear guidelines and enforcement make a difference, especially when companies know customers are paying attention.

Consumers have power, too. Choosing products with fewer chemical treatments isn’t always easy, but asking questions at the store goes a long way. I’ve started looking up Material Safety Data Sheets for things I bring into my home—couches, electronics, kids’ toys—just to get a sense of what’s going in the house.

On the wastewater side, treatment plants equipped to filter out persistent pollutants can trap more of these chemicals before they return to rivers and lakes. Supporting local and national efforts for cleaner water makes a direct impact. Real change comes from a mix of personal choices, public awareness, and policies that demand better from manufacturers.

The story of 2,4,6-Tribromophenol serves as a reminder that what’s good for fire safety today shouldn’t cost us clean air, water, and health tomorrow. The push for safer chemicals keeps moving, powered by people who educate themselves and companies willing to innovate.

2,4,6-Tribromophenol barely makes headlines, but folks who work in labs, factories, or even customs offices know it deserves respect. Used in flame retardants, wood preservatives, and some pharmaceuticals, this white powder isn’t just another shelf-filler. It brings serious health and environmental risks if ignored. A whiff in a storeroom or a spill near the sink can mean headaches, skin rashes, or much bigger trouble down the line.

Keeping this chemical stored right isn’t about following some checklist. Heat, light, and moisture transform harmless tasks into disasters. Strong chemicals don’t need much encouragement to start reacting. Dry, cool, and well-ventilated sites stop the stuff from decomposing or leaking fumes. Use airtight containers made of materials that don’t corrode. Seal them tight. Glass, high-grade plastics, and steel work well if checked for signs of wear. Containers should carry crystal-clear hazard labels—no faded tape or handwritten scrawl—so nobody grabs the wrong jar in a rush.

Storing near acids or strong alkalis? Bad plan. 2,4,6-Tribromophenol can break down or create toxic byproducts. A dry, locked cabinet, kept away from sunlight and incompatible chemicals, solves a lot of problems before they start. Spill kits, gloves, and goggles stay nearby for quick defense, not jammed deep in the storeroom. Folks who work with it could face months of itchy skin or chest pain if splash protection goes missing.

No chemical sticks around forever. Drips, unused stocks, and leftovers build up. Pitching this stuff down a drain is out of the question. Local water systems can’t handle persistent organic pollutants—not even close. Once this compound gets into rivers or soil, it lingers. Wildlife pays the price, and eventually, so do people.

Anything you plan to toss—solid or liquid—needs proper hazardous waste disposal. That’s not overkill. Agencies like the EPA, and health regulators in Europe and Asia, lay out strict steps for chemicals that harm living things at low levels. Incineration works best when done at high temperatures in specialized facilities. These burners destroy toxic molecules before they escape.

Mixing waste types turns disposal into a guessing game. Use solid, puncture-resistant containers for powder. Separate liquids. Tag everything. Anyone moving these containers should have safety training, not just a friendly smile and a strong back. Waste haulers check logs, not trust people’s memory if something leaks on the way out.

Whole-city bans aren’t coming for 2,4,6-Tribromophenol any time soon, but science has tightened regulations. In 2022, the Stockholm Convention tracked emerging pollutants, pushing countries to monitor storage and treatment. China, the EU, the US—no one gets a pass. Stashing drums in a musty basement doesn’t cut it.

If someone finds a stash in a school or workshop, the right move is to call experts or waste contractors—never DIY it. Community trainings, clear safety sheets, and regular inspections build habits. A culture of taking responsibility helps keep accidents out of the headlines and out of neighbors' drinking water.

Guidelines come from hard-learned lessons, not paperwork. Safe storage and disposal protect workers and the ecosystem, one container at a time. Practical care, honest labeling, and prompt waste treatment matter every day, not just after something goes wrong. Knowing the risks helps make smarter decisions, reduces health claims, and cuts cleanup costs later.

| Names | |

| Preferred IUPAC name | 2,4,6-tribromophenol |

| Other names |

Phenol, 2,4,6-tribromo- 2,4,6-TBP TBP 2,4,6-Tribromophenol Phenol, tribromo- tribromophenol |

| Pronunciation | /ˌtraɪˌbroʊmoʊfəˈnoʊl/ |

| Identifiers | |

| CAS Number | 118-79-6 |

| Beilstein Reference | 1209228 |

| ChEBI | CHEBI:34718 |

| ChEMBL | CHEMBL45824 |

| ChemSpider | 12174 |

| DrugBank | DB04476 |

| ECHA InfoCard | 100.004.096 |

| EC Number | 4.1.1.65 |

| Gmelin Reference | 7789 |

| KEGG | C01858 |

| MeSH | D014253 |

| PubChem CID | 15968 |

| RTECS number | SJ8225000 |

| UNII | 0L77T2HY6H |

| UN number | UN2811 |

| CompTox Dashboard (EPA) | DTXSID3020408 |

| Properties | |

| Chemical formula | C6H3Br3O |

| Molar mass | 330.81 g/mol |

| Appearance | White crystalline powder |

| Odor | odorless |

| Density | 3.42 g/cm³ |

| Solubility in water | slightly soluble |

| log P | 3.9 |

| Vapor pressure | 0.00012 mmHg (25°C) |

| Acidity (pKa) | 6.3 |

| Basicity (pKb) | 13.9 |

| Magnetic susceptibility (χ) | -81.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.659 |

| Viscosity | 1.027 Pa.s (90°C) |

| Dipole moment | 2.8 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 341.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −88.4 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -3022.4 kJ/mol |

| Pharmacology | |

| ATC code | D08AE01 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and eye irritation, may cause respiratory irritation, may cause damage to organs through prolonged or repeated exposure, toxic to aquatic life with long lasting effects |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-0-0 |

| Flash point | Flash point: "173 °C |

| Autoignition temperature | 355 °C |

| Lethal dose or concentration | LD₅₀ (rat, oral): 2,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): 5,000 mg/kg (oral, rat) |

| NIOSH | TU9100000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.5 mg/m3 |

| Related compounds | |

| Related compounds |

2,4,6-Trichlorophenol 2,4,6-Triiodophenol 2,4-Dibromophenol 2,6-Dibromophenol 4-Bromophenol Phenol |